Stainless Steel 316 / 316L Needle Valve

Stainless Steel 316 Compression Needle Valve, Suppliers of SS 316 Hydraulic Needle Valve, SS 316L Integral Bonnet Needle Valve, 316 SS High Pressure Needle Valve Manufacturer, Stainless Steel 316L Needle Valve At Factory Price In India.

Vintex Steel & Engg. Co. is a standard trader of Stainless Steel 316 / 316L Needle Valves, It is the maximum broadly and maximum flexible used metal, handy in a broader series of products, finishes and paperwork than any other. A thoughtful of the traits of those Stainless Steel UNS S31600 Needle Valves gives a top notch base for likening individuals of the austenitic own circle of relatives of steels. A 316/316L Needle Valve has a relatively small orifice with a long, tapered seat, and a needle-shaped plunger on the end of a screw, which exactly fits the seat. These 316/316L Needle Valves are an ideal option for isolating or throttling applications.

316 SS Union Bonnet Needle Valve, SS 316L Instrumentation Needle Valve, 316 SS Panel Mount Needle Valve, 316L SS Miniature Needle Valve Stockist, SS 316 Miniature Needle Valve, 1.4401 Needle Valve, UNS S31603 Forged Needle Valve, DIN 1.4404 Hex Needle Valve Supplier, 1/2 Inch Stainless Steel 316 Needle Valve, UNS S31600 Needle Valve Manufacturer In India.

- Material Specification Chart Of SS 316 / 316L Needle Valve

- Stainless Steel 316 / 316L Needle Valve Equivalent Grade

- Most Commonly used Stainless Steel 316 / 316L Needle Valve Types

- Dimension Chart Of SS 316 / 316L Needle Valve

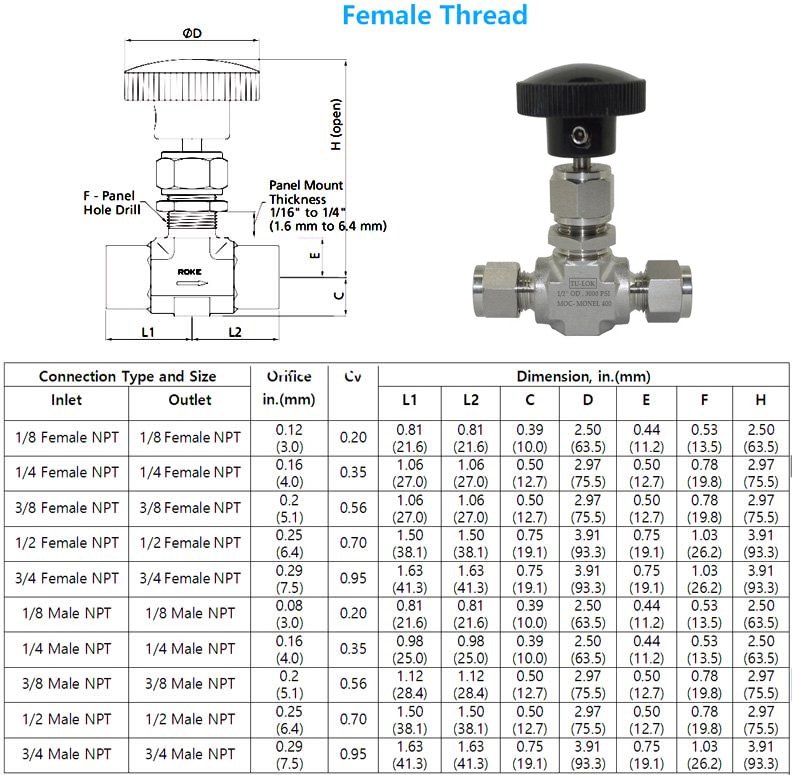

- SS 316 / 316L Female Thread Needle Valve Dimensions Chart

- Stock List Of Stainless Steel 316 / 316L Needle Valve

- Chemical Composition of SS 316 / 316L Needle Valve

- Mechanical Properties of Stainless Steel 316 / 316L Needle Valve

- Stainless Steel 316 / 316L Needle Valve Uses and Application

- Stainless Steel 316 / 316L Needle Valve Export Countries

We manufacture custom precision Stainless Steel 316 Needle & Gauge Valves. We are incorporated with government labs and ISO certifications that show our quality. Stainless Steel UNS S31603 Needle Valves has hovering resistance and temperatures to plenty of corrosive atmospheres. It gives desirable mechanical homes and an incredible resistance in lots of corrosives. It offers particularly ductile mechanical homes throughout an extensive temperature range. Stainless Steel WNR 1.4401 Needle Valves are used on the whole for elements requiring incredible corrosion and robust magnetic homes.

We offer these Needle Valves with an extensive range of specifications according to size, connection types, working pressure range as well as temperature capacity. They also are utilized in coping with and production sodium hydroxide above three hundred Degree C. Stainless Steel WNR 1.4404 Needle Valves are frequently utilized in lead wires, battery additives, transducers, sparking electrodes, and warmth exchangers. It has Moderate Strength Titanium, Excellent Cold Formability, Excellent Weld ability, and Excellent Resistance to High Oxidation. These types of valves are often used in bleed valves with conjunction block. These valves are available for customers in different shapes, forms and in different specifications as per the requirement.

Material Specification Chart Of SS 316 / 316L Needle Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Stainless Steel 316 / 316L Needle Valve Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316 | 1.4401 / 1.4436 | S31600 | SUS 316 | 316S31 / 316S33 | – | Z7CND17‐11‐02 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Most Commonly used Stainless Steel 304 / 304L Needle Valve Types

SS 316 / 316L Screwed End Needle Valve

SS 316 / 316L Tube End Needle Valve

SS 316 / 316L Socket Weld Needle Valve

SS 316 / 316L Angle Needle Valve

SS 316 / 316L Hexagonal Needle Valve

SS 316 / 316L 3 Way Needle Valve

SS 316 / 316L Union Bonnet Needle Valve

SS 316 / 316L Panel Mounted Needle Valve

SS 316 / 316L Forged Needle Valve

SS 316 / 316L Miniature Needle Valve

SS 316 / 316L High Pressure Needle Valve

SS 316 / 316L Bar Stock Needle Valve

Dimension Chart Of SS 316 / 316L Needle Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

SS 316 / 316L Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of Stainless Steel 316 / 316L Needle Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Stainless Steel 316 / 316L Needle Valve

- UNS S31603 Socket Weld End Needle Valve

- 316 Stainless Steel Angle Needle Valve

- 316 Stainless Steel High Pressure Needle Valve

- SS 316 Hydraulic Needle Valve Supplier

- Stainless Steel 316 1rs4 Needle Valve

- 316L Stainless Steel Flanged Needle Valve

- Stainless Steel 316 Flow Control Needle Valves

- DIN 1.4404 Threaded Needle Valve

- Stainless Steel SUS 316L 3 Way Needle Valve

- SS 316L Female Thread Needle Valve

- SS 316 Needle Valve

- 316 SS Screwed End Needle Valve Exporter

- SS 316L Integral Bonnet Needle Valve Stockist

- Stainless Steel 316 1/2 Inch Needle Valve

- Stainless Steel 316L Needle Valve

- 316L Stainless Steel 1/4 Needle Valve

- 316L Stainless Steel Compression Needle Valve

- SS 316 Forged Needle Valve Distributor

- AISI 316L Union Bonnet Needle Valve

- 316 Stainless Steel Screwed Bonnet Valve

- 316 Stainless Steel Hex Needle Valves

- UNS S31603 Needle Valve

- 316 SS Male Needle Valve Manufacturer

- SS 316L Round Body Needle Valve

- DIN 1.4401 Bar Stock Needle Valve

- Grade 316L SS Miniature Needle Valve

- Stainless Steel 316L Panel Mount Needle Valve

- Stainless Steel 316 Industrial Needle Valve Price

- UNS S31600 Female Male Needle Valves

- 316L Stainless Steel 90 Deg Angled Needle Valve

- 316L Stainless Steel Straight Needle Valve

- SS 316 Single Port Gauge Needle Valve Dealer

- SS 316L Instrumentation Needle Valve

- Stainless Steel 316 Multi Port Gauge Needle Valve

Chemical Composition of SS 316 / 316L Needle Valve

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 316 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| SS 316L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

Mechanical Properties of Stainless Steel 316 / 316L Needle Valve

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless Steel 316 / 316L Needle Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment