Nickel Alloy 200 / 201 Needle Valve

Nickel Alloy 200 Integral Bonnet Needle Valve, Nickel Alloy 200 Compression Needle Valve, 201 Nickel High Pressure Needle Valve Manufacturer, Suppliers of Alloy 200 Hydraulic Needle Valve, Nickel 201 Needle Valve At Factory Price In India.

Vintex Steel & Engg. Co. is an accustomed manufacturer and stockist of Nickel Alloy 200 / 201 Needle Valves, which guarantees impeccable completing and is overall performance based.

Configuration of these valves consists of austenite swimming pools enclosed with the aid of using an unremitting ferrite stage. Nickel Alloy UNS N02200 Needle Valves are notably favored for excessive tensile strength, dimensional accuracy, corrosion & chemical resistance and durability. It is nitrogen more advantageous metallic advanced for fighting not unusual place corrosion problems encountered with the steels. It is utilized in zones wherein excessive pressures and temperatures, merged with excessive turbulence and velocities are extreme snags.

Nickel Alloy 200 Union Bonnet Needle Valve, Nickel 201 Panel Mount Needle Valve, UNS N02201 Forged Needle Valve, 201 Nickel Alloy Miniature Needle Valve Stockist, Alloy 201 Miniature Needle Valve, Nickel 200 Instrumentation Needle Valve, DIN 2.4066 Hex Needle Valve Supplier, 2.4068 Needle Valve, 1/2 Inch Nickel 200 Needle Valve, UNS N02200 Needle Valve Manufacturer In India.

- Material Specification Chart Of Nickel Alloy 200 / 201 Needle Valve

- Nickel Alloy 200 / 201 Needle Valve Equivalent Grade

- Most Commonly used Nickel 200 / 201 Needle Valve Types

- Dimension Chart Of Alloy 200 / 201 Needle Valve

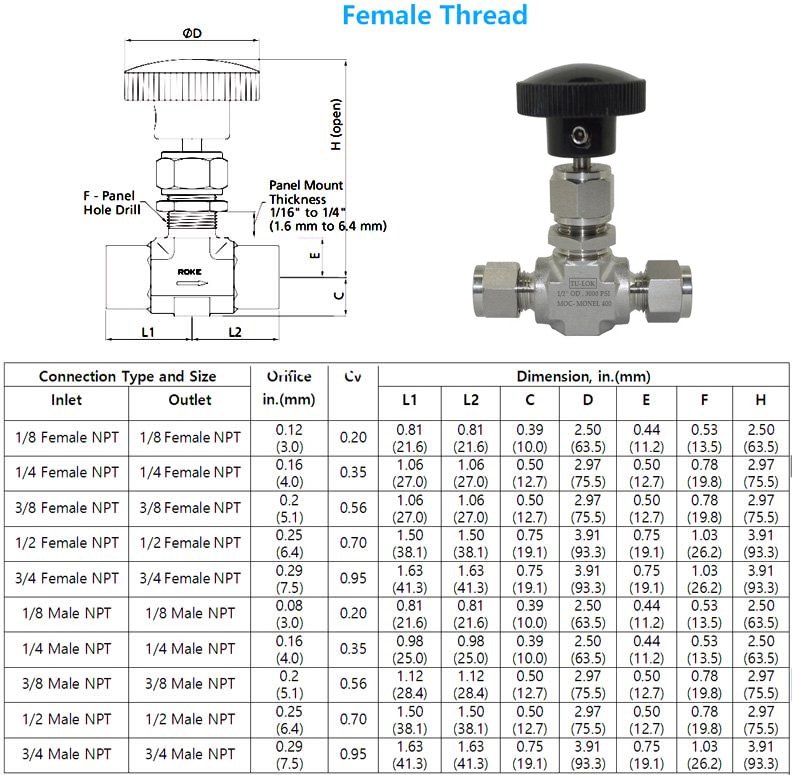

- Nickel 200 / 201 Female Thread Needle Valve Dimensions Chart

- Stock List Of Nickel Alloy 200 / 201 Needle Valve

- Chemical Composition of Nickel Alloy 200 / 201 Needle Valve

- Mechanical Properties of Nickel Alloy 200 / 201 Needle Valve

- Nickel Alloy 200 / 201 Needle Valve Uses and Application

- Nickel Alloy 200 / 201 Needle Valve Export Countries

They have great resistance to corrosion by means of the aid of using brackish water, sea water and clean water. It is usually utilized in offshore water systems, Sea water pipe work, Tubes for ships and electricity plants, fittings and sheathing for deliver hulls, pumps, valves, etc. We offer qualitative these Nickel Alloy 200 Miniature Needle Valves in different sizes and shapes that are being designed as per the national and international standard quality of raw materials. They are regularly used as machined and solid valve and pump components which can be applied for seawater services. Nickel Alloy WNR 2.4068 Needle Valves are utilized in regions wherein stainless-steel cannot be used because of chloride stress-corrosion cracking and in different components requiring excessive degrees of corrosion resistance. Nickel Alloy 201 High Pressure Needle Valves are also offered in customized length sizes and shapes to our esteemed clients. Nickel Alloy 201 Angle Needle Valves have some excellent low temperature properties and respond well to hardening by cold working.

Material Specification Chart Of Nickel Alloy 200 / 201 Needle Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Nickel Alloy 200 / 201 Needle Valve Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | – | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

Most Commonly used Nickel 200 / 201 Needle Valve Types

Nickel Alloy 200 / 201 Screwed End Needle Valve

Nickel Alloy 200 / 201 Tube End Needle Valve

Nickel Alloy 200 / 201 Socket Weld Needle Valve

Nickel Alloy 200 / 201 Angle Needle Valve

Nickel Alloy 200 / 201 Hexagonal Needle Valve

Nickel Alloy 200 / 201 3 Way Needle Valve

Nickel Alloy 200 / 201 Union Bonnet Needle Valve

Nickel Alloy 200 / 201 Panel Mounted Needle Valve

Nickel Alloy 200 / 201 Forged Needle Valve

Nickel Alloy 200 / 201 Miniature Needle Valve

Nickel Alloy 200 / 201 High Pressure Needle Valve

Nickel Alloy 200 / 201 Bar Stock Needle Valve

Dimension Chart Of Alloy 200 / 201 Needle Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Nickel 200 / 201 Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of Nickel 200 / 201 Needle Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Nickel Alloy 200 / 201 Needle Valve

- 200 Nickel Alloy Flanged Needle Valve

- Alloy 200 Female Thread Needle Valve

- Nickel Alloy 200 Hydraulic Needle Valve Supplier

- Nickel 201 Flow Control Needle Valves

- Nickel Alloy 200 1/4 Needle Valve

- 201 Nickel Alloy Compression Needle Valve

- DIN 2.4066 Threaded Needle Valve

- Nickel 200 1/2 Inch Needle Valve

- Nickel Alloy 200 Needle Valve

- Alloy 200 Integral Bonnet Needle Valve Stockist

- Nickel 200 High Pressure Needle Valve

- Nickel Alloy 201 Angle Needle Valve

- Nickel JIS NW 2200 3 Way Needle Valve

- Nickel 201 1rs4 Needle Valve

- UNS N02201 Socket Weld End Needle Valve

- Alloy 201 Screwed End Needle Valve Exporter

- Nickel Alloy 200 Needle Valve

- Nickel Alloy 200 Industrial Needle Valve Price

- 201 Nickel Alloy 90 Deg Angled Needle Valve

- Nickel Alloy 201 Miniature Needle Valve

- Nickel Alloy 200 Round Body Needle Valve

- 201 Nickel Alloy Screwed Bonnet Valve

- Nickel 200 Multi Port Gauge Needle Valve

- Nickel 200 Union Bonnet Needle Valve

- UNS N02200 Needle Valve

- Nickel Alloy 200 Forged Needle Valve Distributor

- Alloy 200 Instrumentation Needle Valve

- Nickel Alloy 200 Male Needle Valve Manufacturer

- UNS N02200 Female Male Needle Valves

- 201 Nickel Alloy Hex Needle Valves

- Nickel 201 Panel Mount Needle Valve

- DIN 2.4068 Bar Stock Needle Valve

- Alloy 201 Single Port Gauge Needle Valve Dealer

- 201 Nickel Alloy Straight Needle Valve

Chemical Composition of Nickel Alloy 200 / 201 Needle Valve

| Grade | Ni | Fe | Cu | C | Mn | S | Si |

| 200 | 99.0 min | 0.40 | 0.25 | 0.15 | 0.35 | 0.01 | 0.35 |

| 201 | 99.0 min | 0.40 | 0.25 | 0.02 | 0.35 | 0.01 | 0.35 |

Mechanical Properties of Nickel Alloy 200 / 201 Needle Valve

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200/201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

Nickel Alloy 200 / 201 Needle Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment