Monel 400 / K500 Tube Plug

Monel 400 Tapered Tube Plug, Monel 400 Tube Plug, Alloy 400 Header Plug, K500 Monel Two-Piece Tube Plug Manufacturer India, Suppliers of Monel Alloy K500 Heat Exchanger Tube Plug, Monel K500 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular trading unit of Monel Alloy 400 / K500 Tube Plug, which has wonderful corrosion resistance in an intensive series of media.

It is austenitic nickel-chromium metallic and the higher content material of carbon elements an augmented yield and tensile strength. Monel Alloy UNS N04400 Tube Plug is most customarily utilized in Boilers, petroleum refineries, Condensers, Heat exchangers, and more. It is being presented by way of its advanced content material of carbon unearths makes use of at excessive temperatures. As well, it’s far used broadly within the refrigeration, chemical, meals and paper processing industries.

Monel Alloy UNS N05500 Tube Plug are used for bendy steel hose, bellows, tubing, spinning, and lots of different stainless functions. Mechanical properties, chemical composition, corrosion / oxidation resistance and weldability provide the greatest flexible overall performance alloys at relatively low cost. Facilitated with colossal business expertise and expertise on this commercial enterprise realm, we’re affianced in offering a huge plethora of this alloy, that’s frequently utilized in textile, pulp paper and chemical equipment, for corrosion resistance.

Monel K500 Boiler Tube Plug, UNS N04400 Tube Plug, UNS N05500 Metal Tapered Tube Plugs, DIN 2.4375 Condenser Tube Plug Supplier, Nickel Alloy 400 Expansion Tube Plug, 2.4360 Tube Plug, Alloy K500 One-Piece Tube Plug Stockist, Monel® Alloy 400 High Pressure Tube Plug Manufacturer In India.

- Material Specification Chart Of Monel 400 / K500 Tube Plug

- Monel 400 / K500 Tube Plug Equivalent Grade

- Most Commonly used Monel 400 / K500 Tube Plug Types

- Monel 400 / K500 Tube Plug Sizes

- Monel 400 / K500 Threaded Tapered Plug Sizes

- Monel 400 / K500 Two-Piece Metal Tube Plug Sizes

- Stock List Of Monel 400 / K500 Tube Plug

- Chemical Composition of Alloy 400 / K500 Tube Plug

- Mechanical Properties of Monel 400 / K500 Tube Plug

- Monel 400 / K500 Tube Plug Uses and Application

- Monel 400 / K500 Tube Plug Export Countries

Using state-of-the-art and superior strategies of fabrication, this presented variety is advanced with the aid of using awesome grade inputs underneath the supervision of skilled personnel. Monel Alloy WNR 2.4361 Tube Plug plays higher than different austenitic stainless steels because of the better alloying of nickel and molybdenum. It is frequently utilized in software scrubber assemblies, acid and fertilizer manufacturing equipment. It has a few splendid functions to provide together in company of reliable, rugged, powerful and more.

Additionally, Monel Alloy WNR 2.4375 Tube Plug has a few world-magnificence functions to provide together with excessive finish, longer life, reliable, and more. Using foremost magnificence primary fabric alongside superior tackles, gear and machinery; those presented are synthetic beneath the route of skilled personnel. It may be welded the usage of maximum of the resistance and fusion methods. They are used due to the fact they’re now no longer touchy to intergranular corrosion after heating within the carbide precipitation variety of 425-850 Degree C.

Material Specification Chart Of Monel 400 / K500 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Monel 400 / K500 Tube Plug Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Monel K500 | 2.4375 | N05500 | – | – | – | – | – |

Most Commonly used Monel 400 / K500 Tube Plug Types

Monel 400 / K500 Tapered Tube Plug

Monel 400 / K500 Heat Exchanger Tube Plug

Monel 400 / K500 Threaded Tapered Plug

Monel 400 / K500 One-Piece Tube Plug

Monel 400 / K500 Two-Piece Tube Plug

Monel 400 / K500 Metal Tapered Tube Plug

Monel 400 / K500 Expandable Tube Plug

Monel 400 / K500 Boiler Tube Plug

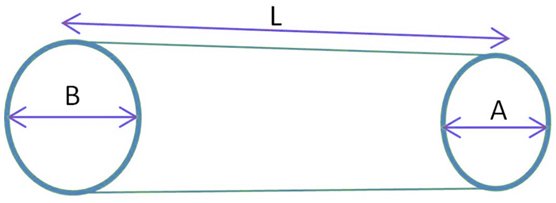

Monel 400 / K500 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Monel 400 / K500 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Monel 400 / K500 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Monel 400 / K500 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy 400 / K500 Tube Plug

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 0.010 max | 27.00 – 33.00 | 0.5 – 2 | 63.00 min |

Mechanical Properties of Monel 400 / K500 Tube Plug

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

| Monel K500 | 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

Monel 400 / K500 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment