Hastelloy B2 Tube Plug

Suppliers of Hastelloy Alloy B2 Heat Exchanger Tube Plug, Hastelloy B2 Tapered Tube Plug, B2 Hastelloy Two-Piece Tube Plug Manufacturer India, Alloy B2 Header Plug, Hastelloy B2 Tube Plug, Hastelloy B2 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular stockist of Hastelloy Alloy B2 Tube Plug, which has oxidation proof against 1800 Degree F.

Exactly built making the usage of supreme-grade fabric at the side of modern-day strategies and tools, those presented merchandise are tremendously applauded. It has some of first-rate functions to provide like smooth to install, abrasion resistant nature, leakage loose production and more. Hastelloy Alloy UNS N10665 Tube Plug is utilized in processing gadget and oil and fueloline exploration – piping, warmth exchangers and tubing. It resists sulfide chloride and pressure corrosion atmospheres, and is resistance to chloride crevice and pitting corrosion. It is normally utilized in Machinery Handling Fatty and Organic Acids, Chemical Tankers and Storage, etc.

Nickel Alloy B2 Expansion Tube Plug, Hastelloy B2 Boiler Tube Plug, UNS N10665 Metal Tapered Tube Plugs, DIN 2.4617 Condenser Tube Plug Supplier, UNS N10665 Tube Plug, 2.4617 Tube Plug, Alloy B2 One-Piece Tube Plug Stockist, Hastelloy® Alloy B2 High Pressure Tube Plug Manufacturer In India.

- Material Specification Chart Of Hastelloy B2 Tube Plug

- Hastelloy B2 Tube Plug Equivalent Grade

- Most Commonly used Hastelloy B2 Tube Plug Types

- Hastelloy B2 Tube Plug Sizes

- Hastelloy B2 Threaded Tapered Plug Sizes

- Hastelloy B2 Two-Piece Metal Tube Plug Sizes

- Stock List Of Hastelloy B2 Tube Plug

- Chemical Composition of Alloy B2 Tube Plug

- Mechanical Properties of Hastelloy B2 Tube Plug

- Hastelloy B2 Tube Plug Uses and Application

- Hastelloy B2 Tube Plug Export Countries

It is utilized in Chemical transport, garage and processing – stress vessels, warmth exchangers, tanks, piping, etc. They are significantly utilized in tidewater energy plants, marine service, and more. Hastelloy Alloy WNR 2.4617 Tube Plug particularly excels in repelling corrosion to warm sulphuric acids while likened to conservative alloys. And to fulfil with the numerous and growing requisites, we’re enthusiastically indulged in imparting a huge and wealthy in great collection of those to our reputable customers. It is commercially natural nickel, proof against diverse lowering chemicals & caustic alkalis, and has exact magnetostrictive properties. It gives decrease carbon content material to save you embrittlement through inter-granular carbon at multiplied temperatures.

It indicates excessive power and outstanding corrosion resistance in a variety of acidic and alkaline environments and it is mainly appropriate for lowering conditions. It has corrosion resistance in an intensive variety of marine and chemical environments – from natural water to non-oxidizing mineral acids, salts and alkalis. It combines the outstanding corrosion resistance feature with the introduced blessings of more power and hardness. Nickel-Alloy B2 Tube Plug are tremendously made-up underneath the path of successful executives through the usage of accepted great fabric. It is proof against a huge variety of corrosive media, and has first-rate oxidation resistance as much as 2200 Degree F. It has outstanding resistance to lowering and oxidizing acids, and resists spalling even below extreme thermal biking conditions.

Material Specification Chart Of Hastelloy B2 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Hastelloy B2 Tube Plug Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. |

| Hastelloy B2 | N10665 | 2.4617 |

Most Commonly used Hastelloy B2 Tube Plug Types

Hastelloy B2 Tapered Tube Plug

Hastelloy B2 Heat Exchanger Tube Plug

Hastelloy B2 Threaded Tapered Plug

Hastelloy B2 One-Piece Tube Plug

Hastelloy B2 Two-Piece Tube Plug

Hastelloy B2 Metal Tapered Tube Plug

Hastelloy B2 Expandable Tube Plug

Hastelloy B2 Boiler Tube Plug

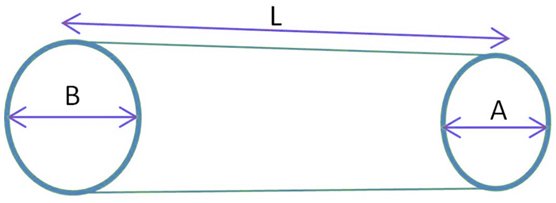

Hastelloy B2 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Hastelloy B2 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Hastelloy B2 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Hastelloy B2 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy B2 Tube Plug

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| Alloy B2 | 0.02 max | 1.0 max | 0.1 max | 0.03 max | 1.0 max | Bal | 1.0 max | 2.0 max | 26 – 30 | 0.04 max |

Mechanical Properties of Hastelloy B2 Tube Plug

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 9.2 g/cm3 | 1370 °C (2500 ºF ) | Psi – 1,10,000 , MPa – 760 | Psi – 51000 , MPa – 350 | 40 % |

Hastelloy B2 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment