Titanium Gr 2 / Gr 5 Tube Plug

Titanium Gr 2 Tube Plug, Titanium Gr 2 Tapered Tube Plug, Suppliers of Titanium Alloy Gr 5 Heat Exchanger Tube Plug, Ti Alloy Grade 2 Header Plug, Grade 5 Titanium Two-Piece Tube Plug Manufacturer India, Titanium Gr 5 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular supplying unit of Titanium Gr.2 / Gr.5 Tube Plug, which has higher excessive temperature electricity and mechanical strength.

It is basically a fashionable carbon grade with titanium stabilization and is comparable in precept to the maintenance. It is greater proof against preferred corrosion and pitting/crevice corrosion than the traditional chromium nickel austenitic steels. Titanium UNS R50400 Tube Plug may be regularly utilized in Pulp and Paper Equipment, Heat exchangers, Propeller shafts, Fittings, Dyeing Equipment, Exterior Architectural additives in Marine Coastal Areas, and more.

It is drastically used within the oil and fueloline and chemical industries for its price powerful corrosion resistance and simplicity of fabrication. The low carbon model is immune from sensitization (grain boundary carbide precipitation). Titanium UNS N56400 Tube Plug is drastically utilized in heavy gauge welded additives (over approximately 6mm). The decrease carbon content material minimizes deleterious carbide precipitation due to welding. We deliver those to loads of clients which include fabricators of strain vessels, business boilers and warmth exchangers.

Titanium Grade 2 Expansion Tube Plug, DIN 3.7035 Condenser Tube Plug Supplier, Titanium Gr 5 Boiler Tube Plug, UNS R50400 Metal Tapered Tube Plugs, 3.7165 Tube Plug, UNS R56400 Tube Plug, Ti Alloy Grade 5 One-Piece Tube Plug Stockist, Titanium Alloy Gr 2 High Pressure Tube Plug Manufacturer In India.

- Material Specification Chart Of Titanium Gr 2 / Gr 5 Tube Plug

- Titanium Gr 2 / Gr 5 Tube Plug Equivalent Grade

- Most Commonly used Titanium Gr 2 / Gr 5 Tube Plug Types

- Titanium Gr 2 / Gr 5 Tube Plug Sizes

- Titanium Gr 2 / Gr 5 Threaded Tapered Plug Sizes

- Titanium Gr 2 / Gr 5 Two-Piece Metal Tube Plug Sizes

- Stock List Of Titanium Gr 2 / Gr 5 Tube Plug

- Chemical Composition of Ti Alloy Gr 2 / Gr 5 Tube Plug

- Mechanical Properties of Titanium Gr 2 / Gr 5 Tube Plug

- Titanium Gr 2 / Gr 5 Tube Plug Uses and Application

- Titanium Gr 2 / Gr 5 Tube Plug Export Countries

Benefits of the use of those are that it has improved carbon content material warmness resistant qualities, more tensile yield strength, and more brief and longtime creep strength. By means of its better carbon content material, it has a few utility at expanded temperatures, as does stabilize this alloy. Titanium WNR 3.7035 Tube Plug has a few remarkable functions to provide together with ideal finish, rugged, excessive electricity and greater. They are really austenitic steels that incorporate molybdenum, which will increase their resistance to many chemical corrodes and marine environments.

It is the same old molybdenum bearing grade, in significance to among the austenitic steels. It gives a decrease carbon content material that minimizes carbide precipitation and improves weldability. It has remarkable resistance to oxidation beneath regular temperatures to 2000 Degree F. Titanium WNR 3.7165 Tube Plug is a medium carbon austenitic steel, for excessive temperature programs together with furnace components and warmth remedy equipment. It gives a few remarkable functions together with quite durable, rugged, low preservation and greater.

Material Specification Chart Of Titanium Gr 2 / Gr 5 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Titanium Gr 2 / Gr 5 Tube Plug Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 2 | 3.7035 | R50400 |

| Titanium Gr. 5 | 3.7165 | R56400 |

Most Commonly used Titanium Gr 2 / Gr 5 Tube Plug Types

Titanium Tapered Tube Plug

Titanium Heat Exchanger Tube Plug

Titanium Threaded Tapered Plug

Titanium One-Piece Tube Plug

Titanium Two-Piece Tube Plug

Titanium Metal Tapered Tube Plug

Titanium Expandable Tube Plug

Titanium Boiler Tube Plug

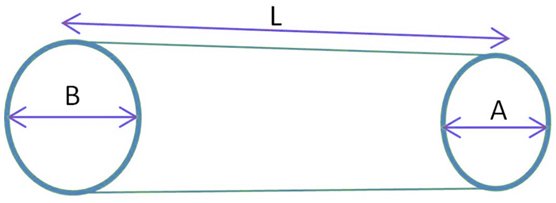

Titanium Gr 2 / Gr 5 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Titanium Gr 2 / Gr 5 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Titanium Gr 2 / Gr 5 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Titanium Gr 2 / Gr 5 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Ti Alloy Gr 2 / Gr 5 Tube Plug

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | – | – |

| Ti Grade5 | 90 min | – | 0.25 max | – | – | 0.2 max | 6 min | 4 min |

Mechanical Properties of Titanium Gr 2 / Gr 5 Tube Plug

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20 % |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Titanium Gr 2 / Gr 5 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment