ASTM A182 Alloy Steel F11 Tube Plug

Alloy Steel A182 F11 Tapered Tube Plug, Alloy Steel F11 Tube Plug, Alloy Steel F11 Header Plug, Suppliers of Alloy Steel F11 Heat Exchanger Tube Plug, ASTM A182 F11 Alloy Steel Two-Piece Tube Plug Manufacturer India, Chrome Moly F11 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular supplier of Alloy Steel ASTM A182 F11 Tube Plug, which had been first of all advanced to be used on small-length excessive strain piping.

Supported via way of means of the maximum wide-ranging product line within the marketplace and a large listing that makes all our merchandise willingly obtainable, we’re the as no. one dealer for the oil, chemical, energy, production and marine industries everywhere in the world. Alloy Steel ASME SA 182 F11 Tube Plug has a few incredible blessings including High tensile strength, High compressive strength, Range of corrosion safety structures, Wide variety of diameters and wall thickness, etc. They are clean to apprehend on the lengthy tapered hub that is going regularly over to the wall thickness from a pipe or fitting.

Alloy Steel ASTM A182 F11 Boiler Tube Plug, ASTM A182 F11 Alloy Steel Expansion Tube Plug, CrMo A182 F11 High Pressure Tube Plug, ASME SA 182 F11 Alloy Steel One-Piece Tube Plug Stockist, UNS K11597 Metal Tapered Tube Plugs, DIN 1.7338 Condenser Tube Plug Supplier, 1.7338 Tube Plug Manufacturer In India.

- Material Specification Chart Of ASTM A182 Alloy Steel F11 Tube Plug

- ASTM A182 Alloy Steel F11 Tube Plug Equivalent Grade

- Most Commonly used ASTM A182 Alloy Steel F11 Tube Plug Types

- Alloy Steel ASTM A182 F11 Tube Plug Sizes

- Alloy Steel ASTM A182 F11 Threaded Tapered Plug Sizes

- ASTM A182 F11 Alloy Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy Steel A182 F11 Tube Plug

- Chemical Composition of ASTM A182 F11 Alloy Steel Tube Plug

- Mechanical Properties of Alloy Steel A182 F11 Tube Plug

- Alloy Steel ASTM A182 F11 Tube Plug Uses and Application

- ASTM A182 Alloy Steel F11 Tube Plug Export Countries

They are used within the piping structures relying upon the fluid, cloth of production, connecting device etc. ASTM A182 Alloy Steel F11 Tube Plug is distinctly pricey due to its lengthy neck, however is desired for excessive pressure applications. We provide production centers to the ones of energy generation, chemicals, and chemical fertilizers. They are supplied in numerous types in kind and form, and their cloth too is various according by means of the sort of fluid and carrier environment. They are usually utilized in excessive strain and / or excessive temperature offerings above 800 Degree F (427 Degree C).

The purpose for that is that the touch surfaces do now no longer suit and there’s no gasket that has one kind on one facet and every other kind on the opposite facet. It is commonly within the form of a disc and is used to attach tubes collectively or to attach a pipe to a valve, tee, choke or different component. ASME SA 182 Alloy Steel F11 Tube Plug has a few remarkable capabilities to provide including durable, correct composition, sturdier and more. Extensively utilized in multiple sectors and industries for making various forms of materials, they’re especially factory-made via way of means of our professionals utilizing top class grade alloys.

Material Specification Chart Of ASTM A182 Alloy Steel F11 Tube Plug

| Standard | ASTM A182 / ASME SA182 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

ASTM A182 Alloy Steel F11 Tube Plug Equivalent Grade

| Grade | DIN | UNS | EN |

| ASTM A182 Gr. F11 | 1.7338 | K11597 | 1-1/4Cr-1/2Mo |

Most Commonly used ASTM A182 Alloy Steel F11 Tube Plug Types

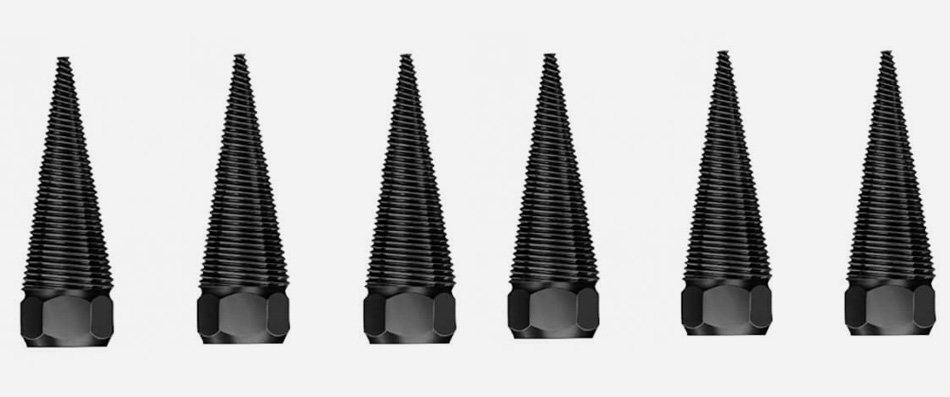

Alloy Steel F11 Tapered Tube Plug

Alloy Steel F11 Heat Exchanger Tube Plug

Alloy Steel F11 Threaded Tapered Plug

Alloy Steel F11 One-Piece Tube Plug

Alloy Steel F11 Two-Piece Tube Plug

Alloy Steel F11 Metal Tapered Tube Plug

Alloy Steel F11 Expandable Tube Plug

Alloy Steel F11 Boiler Tube Plug

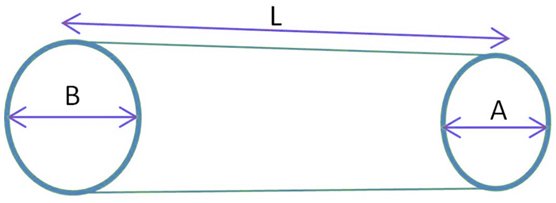

Alloy Steel ASTM A182 F11 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy Steel ASTM A182 F11 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A182 F11 Alloy Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A182 F11 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A182 F11 Alloy Steel Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F11 | 0.15 max | 0.3-0.6 | 0.5 – 1 | 0.03 | 0.03 | 1 – 1.5 | 0.044 – 0.65 |

Mechanical Properties of Alloy Steel A182 F11 Tube Plug

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|

| 205 | 415 | 20 |

Alloy Steel ASTM A182 F11 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment