ASTM A105 Carbon Steel Tube Plug

Suppliers of Carbon Steel A105 Heat Exchanger Tube Plug, Carbon Steel A105 Header Plug, Carbon Steel A105 Tapered Tube Plug, ASTM A105 Carbon Steel Two-Piece Tube Plug Manufacturer India, Carbon Steel Tube Plug, CS A105 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a widely known manufacturer of Carbon Steel ASTM A105 Tube Plug, which is powerful to steam and seawater at hovering temperatures.

Based on a discipline corrosion evaluation, it become decided on because the favored material of production for the off-fueloline quench elbow of a business chlorinated organics. It is a maximum flexible nickel-chromium-molybdenum-tungsten alloy with advanced resistance to each uniform and localized corrosion as nicely to a huge kind of combined business chemical substances. Carbon Steel ASME SA 105 Tube Plug is commercially unalloyed wrought Nickel by equal features however by low content material of carbon for to save you embrittlement with the aid of using inter-granular carbon at excessive temperatures.

ASTM A105 CS Metal Tapered Tube Plugs, CS A105 Condenser Tube Plug Supplier, Carbon Steel A105 Boiler Tube Plug, ASME SA 105 Carbon Steel One-Piece Tube Plug Stockist, CS A105 High Pressure Tube Plug, ASTM A105 Carbon Steel Expansion Tube Plug, Carbon Steel A105 Tube Plug Manufacturer In India.

- Material Specification Chart Of ASTM A105 Carbon Steel Tube Plug

- Most Commonly used ASTM A105 Carbon Steel Tube Plug Types

- Carbon Steel ASTM A105 Tube Plug Sizes

- Carbon Steel ASTM A105 Threaded Tapered Plug Sizes

- ASTM A105 Carbon Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Carbon Steel A105 Tube Plug

- Chemical Composition of ASTM A105 Carbon Steel Tube Plug

- Mechanical Properties of Carbon Steel A105 Tube Plug

- Carbon Steel ASTM A105 Tube Plug Uses and Application

- ASTM A105 Carbon Steel Tube Plug Export Countries

It merges the exquisite corrosion resistance characteristic by the extra benefits of higher hardness and energy. It has corrosion resistance in an intensive series of chemical and marine atmospheres – from unalloyed water to non-oxidising mineral salts, alkalis and acids. ASTM A105 Carbon Steel Tube Plug indicates exquisite corrosion resistance and excessive energy in an array of alkaline and acidic atmospheres and it is especially suitable for decreasing paperwork. It has incredible resistance to strain corrosion cracking and has corrosion resistant as much as 1800 Deg F. It repels spalling as nicely beneath strict thermal biking paperwork and are efficaciously proof against chlorine-ion SCC.

It has admirable resistance to oxidizing and decreasing acids and is pretty proof against a considerable series of corrosive media. It has high-quality oxidation resistance approximately 2200 Deg F and has hovering creep-rupture potency. ASME SA 105 Carbon Steel Tube Plug became used notably for the filaments of old-fashion incandescent mild bulbs, however those were phased out in lots of countries. It is a greyish-white lustrous steel, that’s a strong at room temperature. It is a mild grey or whitish steel this is gentle sufficient to be reduce by means of a hacksaw and ductile sufficient to be drawn into twine or extruded into diverse shapes. It is commercially unalloyed nickel, proof against some of decreasing caustic and chemical substances alkalis, and has high-quality magnetostrictive attributes.

Material Specification Chart Of ASTM A105 Carbon Steel Tube Plug

| Standard | ASTM A105 / ASME SA105 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Most Commonly used ASTM A105 Carbon Steel Tube Plug Types

Carbon Steel A105 Tapered Tube Plug

Carbon Steel A105 Heat Exchanger Tube Plug

Carbon Steel A105 Threaded Tapered Plug

Carbon Steel A105 One-Piece Tube Plug

Carbon Steel A105 Two-Piece Tube Plug

Carbon Steel A105 Metal Tapered Tube Plug

Carbon Steel A105 Expandable Tube Plug

Carbon Steel A105 Boiler Tube Plug

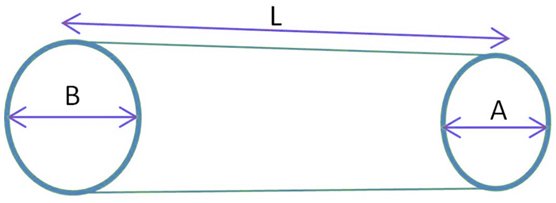

Carbon Steel ASTM A105 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Carbon Steel ASTM A105 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A105 Carbon Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A105 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A105 Carbon Steel Tube Plug

| Element | C | Mn | P | S | Si | Cu | Ni | Cr | Mo | V |

| ASTM A105 | 0.35 max | 0.60–1.05 | 0.035 max | 0.040 max | 0.10–0.35 | 0.40 max | 0.40 max | 0.30 max | 0.12 max | 0.08 max |

Mechanical Properties of Carbon Steel A105 Tube Plug

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |

Carbon Steel ASTM A105 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment