Nickel Alloy 200 Tube Fittings

Nickel Alloy 200 Male Elbow, Nickel 200 Single & Double Ferrule Tube Fittings, Suppliers of ASTM B366 Alloy 200 Female Connector At Factory Price In India.

Vintex Steel & Engg. Co. is an accredited stockiest of Nickel Alloy 200 Instrumentation Tube Fittings, which are as properly used for Line Pipe and Sour Service Line Pipes.

They Are Developed For Energy-Related Applications Involving Oil And Gas Drilling. It is frequently utilized in Transformers, Heat Exchangers, Oil Refineries, Brine Heaters, Space Research, Steel industry, Engineering projects, General Piping Industry, and more. It can face up to High Temperature and Pressure, Corrosion proof, Immaculate finish, Rigid & compacted design, Precise holes alignment, Dimensional accuracy, and more. They are having sturdy corrosion resistant properties, and locating use as residence pipes, for heating packages and others. Global necessities of our Nickel 200 Tube Fittings are non-popular as to the approach concerned in making, shaping and treating of metal. We are counted among the reckoned names within the industry, engaged in buying and selling big selection of Tube Fittings which are functionally superior in nature and are dimensionally accurate. It addresses welded and seamless metal line pipe for the pipeline transportation structures in herbal fuelling and petroleum industries.

Nickel 200 Tube To Union, UNS N02200 Tube Fittings, ASME SB366 Nickel Alloy 200 Bulkhead Elbow Stockist, DIN 2.4066 Union Elbow Supplier, Nickel Alloy 200 Male Connector Manufacturer In India.

- Material Specification Chart Of Nickel Alloy 200 Tube Fittings

- Nickel Alloy 200 Instrumentation Fittings Equivalent Grade

- Most Commonly used Nickel Alloy 200 Tube Fittings Types

- Nickel Alloy 200 Tube Fittings Pressure Rating

- Stock List Of Nickel Alloy 200 Instrumentation Fittings

- Chemical Composition of Alloy 200 Compression Tube Fittings

- Mechanical Properties of Nickel Alloy 200 Tube Fittings

- Nickel Alloy 200 Compression Fittings Uses and Application

- Nickel Alloy 200 Tube Fittings Export Countries

All those are greatly useful in effective manufacturing of Nickel 200 instrumentation Tube Fittings. This product is well known to form the passive layer and oxide when it is in contact with the oxidizing environment that leads an inner surface of the fitting to be unaffected by general corrosion. Our range of Instrumentation Fittings include Nickel 200 Tube Fittings, Nickel 201 Male Connectors, Nickel 200 Bulkhead Union, Nickel 201 Union Elbow, Nickel 200 Union Tee and more. We are manufacturers and suppliers of UNS N02200 Instrumentation Fittings that have a 0.15% Carbon content giving them excellent thermal and electrical properties, making them slightly different from their 200 version. We use pure quality Nickel 200, which helps us to maintain many quality features such as excellent corrosion resistance and higher mechanical strength.

Material Specification Chart Of Nickel Alloy 200 Tube Fittings

| Specifications | ASTM B366 / ASME SB366 |

|---|---|

| Size | 1/16 in. to 2 in. & 2mm to 50 mm. |

| Dimensional Range | 1/16 to 2 inches (imperial); 2 to 50 mm (metric) |

| Working Pressures | Upto 2000 to 6000 PSI |

| Thread Type | NPT – ASME B1.20.1, SAE AS71051 | ISO/BSP Parallel – ISO 228 | ISO/BSP Tapered – ISO 7, BS EN 10226-1 | SAE (Unified) – ASME B1.1 |

| End Connections | NPT, ISO/BP, SAE/MS, AN, weld ends, port connectors, sanitary flanges, tube adapters |

| Types | Tube to Union, Tube to Male, Tube to Female, Instrument Pipe Fittings, Accessories |

| Equivalent To | SWAGELOK, PARKER, DK-LOK, HOKE |

| Max Working Pressure | 8MPa | 1200psi Depending on The Tubing Material |

| Working Temperature | -40°C—250°C | -40°F—482°F Depending on The Tubing Material |

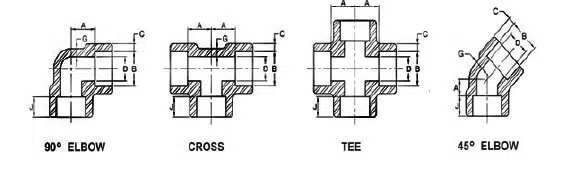

| Configurations | Straights, elbows, tees, crosses, caps, plugs, nuts and ferrules Chromatograph and Column End |

| Tube Fitting uses & application |

|

| Material Test Certificates (MTC) for Tube Fitting as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Nickel Alloy 200 Instrumentation Fittings Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

Most Commonly used Nickel Alloy 200 Tube Fittings Types

Nickel Alloy 200 Tube Fittings Pressure Rating

| NPT/ISO Pipe Size in. | Tube Fittings | |

|---|---|---|

| Male | Female | |

| psig (bar) | psig (bar) | |

| 1/16 | 11 000 (757) | 6 700 (461) |

| 1/8 | 10 000 (689) | 6 500 (447) |

| 1/4 | 8 000 (551) | 6 600 (454) |

| 3/8 | 7 800 (537) | 5 300 (365) |

| 1/2 | 7 700 (530) | 4 900 (337) |

| 3/4 | 7 300 (502) | 4 600 (316) |

| 1 | 5 300 (365) | 4 400 (303) |

| 1 1/4 | 6 000 (413) | 5 000 (344) |

| 1 1/2 | 5 000 (344) | 4 600 (316) |

| 2 | 3 900 (268) | 3 900 (268) |

| OD | OD Actual | Thread Designation – Nominal Size | Thread per inch | |

| (fraction inch) | (inches) | (inches) | NPT | BSP |

| 5/16 | 0.3125 | 1/16 | 27 | 28 |

| 13/32 | 0.405 | 1/8 | 27 | 28 |

| 35/64 | 0.540 | 1/4 | 18 | 19 |

| 43/64 | 0.675 | 3/8 | 18 | 19 |

| 27/32 | 0.840 | 1/2 | 14 | 14 |

| 1-3/64 | 1.050 | 3/4 | 14 | 14 |

| 1-5/16 | 1.315 | 1 | 11-1/2 | 11 |

| 1-21/32 | 1.660 | 1-1/4 | 11-1/2 | 11 |

| 1-29/32 | 1.900 | 1-1/2 | 11-1/2 | 11 |

| 2-3/8 | 2.375 | 2 | 8 | 11 |

| 2-7/8 | 2.875 | 2-1/2 | 8 | 11 |

| 3-1/2 | 3.5 | 3 | 8 | 11 |

| 4 | 4.0 | 3-1/2 | 8 | 11 |

| 4-1/2 | 4.5 | 4 | 8 | 11 |

| 5-5/8 | 5.563 | 5 | 8 | 11 |

| 6-5/8 | 6.625 | 6 | 8 | 11 |

Other Related Products

Test Certificates Of Nickel Alloy 200 Tube Fittings

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Nickel Alloy 200 Instrumentation Fittings

- DIN 2.4066 Push-Connect Tube Fittings

- Nickel Alloy 200 Hydraulic Fittings

- 200 Nickel Alloy Tube To Female Pipe

- Nickel Alloy 200 Tube Fittings

- Nickel 200 Flared Tube Fittings Exporter

- Nickel 200 Tube To Union

- UNS N02200 Imperial Tube Fittings

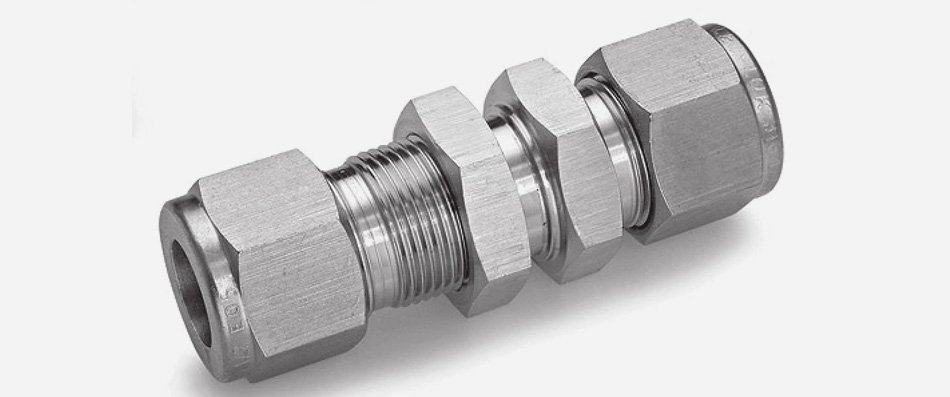

- Alloy 200 Double Ferrule Fittings Supplier

- Nickel Alloy 200 Swagelok Tube Fittings

- ASTM B366 Nickel Alloy 200 NPT Fittings

- Nickel Alloy JIS NW 2200 Male Connector

- Alloy 200 Single Ferrule Fittings Stockist

- Nickel Alloy 200 Parker Tube Fittings

- Nickel Alloy 200 Tube To Male Fittings

- Nickel Alloy 200 Ferrule Fittings

- Alloy 200 Instrumentation Fittings

- Nickel 200 Compression Tube Fittings

- Nickel Alloy 200 Tube Plug Dealer

- Nickel Alloy 200 Union Elbow

- UNS N02200 Bulkhead Elbow

- Nickel Alloy 200 Compression Tube Fittings

- Alloy 200 90 Deg Male Adapter

- DIN 2.4066 Union Cross

- UNS N02200 Male Adapter

- Nickel Alloy 200 Tube End Closure

- 200 Nickel Alloy Back Ferrule Fittings

- Nickel 200 Bulkhead Reducing Union

- Nickel Alloy 200 Female Connector

- 200 Nickel Alloy Reducing Union Tee

- Nickel 200 45 Deg Positionable Male Elbow

- ASME SB 366 Nickel Alloy 200 Female Branch Tee

- Nickel 200 Reducing Union Manufacturer

- Nickel 200 Bulkhead Union Distributor

- Nickel 200 Industrial Tube Fittings Price

Chemical Composition of Alloy 200 Compression Tube Fittings

| Grade | Ni | Fe | Cu | C | Mn | S | Si |

| 200 | 99.0 min | 0.40 | 0.25 | 0.15 | 0.35 | 0.01 | 0.35 |

Mechanical Properties of Nickel Alloy 200 Tube Fittings

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

Nickel Alloy 200 Compression Fittings Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment