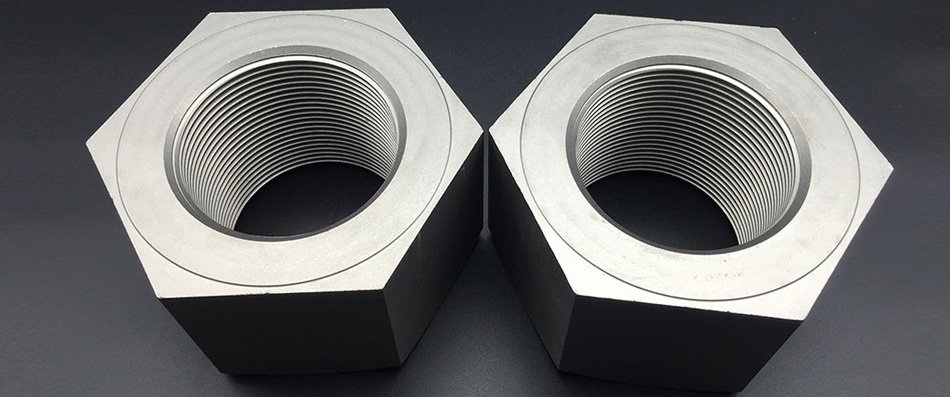

Duplex Steel UNS S31803 Hex Nuts

Duplex Steel S31803 Hexagon Nuts, Duplex Steel UNS S31803 Slotted Hex Nuts, Duplex Stainless Steel 2205 Hex Head Nut, Duplex Steel S31803 Industrial Hex Nuts, Suppliers of Duplex Steel S31803 Hex Nut, SAF 2205 Heavy Hex Nuts At Factory Price In India.

Vintex Steel & Engg. Co. is one of the noticeable exporter of Duplex S31803 Hex Nuts, which are by far drastically utilized in heavy gauge welded components.

The molybdenum offers Hex Nuts higher standard corrosion resistant properties, mainly better resistance to pitting and crevice corrosion in chloride environments. Concentrations of salt in seawater can range in Hex Nuts, and splash zones can motive concentrations to growth dramatically from the spray and evaporation. Duplex Steel UNS S32205 Hex Nuts are austenitic steels that include molybdenum, which will increase their resistance to many chemical corrodes and marine environments. It is the decrease carbon model and is immune from sensitization; therefore, it’s far very often utilized in heavy gauge welded components.

Duplex S32205 Machine Hex Nuts, Duplex 2205 Finished Hex Nuts, Duplex Stainless Steel S31803 Long Hex Nut Stockist, ASTM A182 F51 Hex Nuts Supplier, Duplex Stainless Steel 2205 Coupling Nuts, 1.4462 Heavy Hex Nuts, SAF 2205 Heavy Hexagon Nuts, Duplex Steel S32205 Hex Jam Nuts, UNS S31803 Hexagonal Nylon Lock Nut Manufacturer In India.

- Material Specification Chart Of Duplex Steel S31803 Hex Nuts

- Duplex Steel 2205 Hex Nuts Equivalent Grade

- Most Commonly used Duplex Steel S31803 Hex Nuts Types

- Duplex Steel S31803 Hex Nuts Available Standards

- Size Chart of Duplex Steel S31803 Hex Nuts

- Dimensions of Duplex Stainless Steel 2205 Hex Nuts

- Dimensions of Duplex Steel S31803 Heavy Hex Nuts

- Weight Chart Of Duplex Steel 2205 Hex Nuts

- Stock List Of Duplex Steel S31803 Hex Nuts

- Chemical Composition of Duplex Steel S31803 Hex Nuts

- Mechanical Properties of Duplex Steel S31803 Hex Nuts

- Duplex Steel S31803 Hex Nuts Uses and Application

- Duplex Steel S31803 Hex Nuts Export Countries

Duplex Steel Grade 2205 Hex Nuts is drastically used within the oil and fueloline and chemical industries for its fee powerful corrosion resistance and simplicity of fabrication. It is an excessive carbon amendment and advanced to be used in expanded temperature carrier. The austenitic shape of Hex Nuts additionally offers this grade super toughness, even right all the way down to cryogenic temperatures. This filler steel of Hex Nuts is the same, besides that the allowable carbon content material has been confined to the better part of the latter range. It resists oxidation in non-stop carrier at temperatures as much as 1150 Degree C supplied decreasing sulphur gases aren’t gift.

Typical Applications Hex Nuts is utilized in fluidised mattress combustors, kilns, radiant tubes, tube hangers for petroleum refining and steam boilers. The excessive chromium and nickel contents of Hex Nuts offer similar corrosion resistance and advanced resistance to oxidation. Duplex Steel WNR 1.4462 Hex Nuts is a pretty alloyed austenitic stainless-steel used for excessive temperature application. Due to its excessive chromium and nickel content material, it’s far advanced in maximum environments. Also, excessive nickel and chromium contents of Hex Nuts impart super expanded temperature power and resistance to oxidation. It has true resistance to oxidation at temperatures of as much as 1904 Degree F) in intermittent carrier and 2102 Degree F in non-stop carrier. It is broadly utilized in environments in which sulfur dioxide fueloline is gift at excessive temperatures.

Material Specification Chart Of Duplex Steel S31803 Hex Nuts

| Grade | Duplex Steel 2205 (UNS S31803/S32205) |

|---|---|

| Size | Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes |

| Length | 3 mm to 200 mm |

| Hex Nuts | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard | DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads | Unless otherwise specified, the threads shall be rolled or cut and tapped horizontally or vertically |

| Test Certificate | as per EN 10204 / 3.1 Manufacturer Test Certificate |

| Additional Certifications | PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Production process | M24-M100: hot forging , M2-M24: Cold Froging, for custom-made connecting element machining and CNC |

| Head drive | Six-Lobe,Phillips,Phillips/Slot, Slotted etc |

| Surface Coating | Ptfe Coated Nuts Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating |

| finishing | Coatings & Finishes : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide, |

Duplex Steel 2205 Hex Nuts Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

Most Commonly used Duplex Steel S31803 Hex Nuts Types

Duplex Steel S31803 Slotted Hex Nut

- Duplex Steel S31803 Slotted Hex Nut

- S32205 Duplex Steel Hex Slotted Nuts

- UNS S31803 Slotted Castle Nuts

- UNS S32205 Heavy Hex Slotted Nut

- Duplex Steel 2205 Slotted Hex Nut

- 1.4462 Slotted Hex Nut

- SAF 2205 Slotted Hex Nut

Duplex Steel S31803 Heavy Hex Nut

- Duplex Steel S31803 Heavy Hex Nut

- S32205 Duplex Steel Heavy Hex Nuts

- UNS S31803 Heavy Hex Nuts

- UNS S32205 Heavy Duty Nuts

- Duplex Steel 2205 Heavy Hex Nut

- 1.4462 Heavy Hex Nut

- SAF 2205 Heavy Hex Nut

Duplex Steel S31803 Machine Hex Nut

- Duplex Steel S31803 Machine Hex Nut

- S32205 Duplex Steel Machine Hex Nuts

- UNS S31803 Machine Hex Nuts

- UNS S32205 Hex Machine Screw Nuts

- Duplex Steel 2205 Machine Hex Nut

- 1.4462 Machine Hex Nut

- SAF 2205 Machine Hex Nut

Duplex Steel S31803 Finished Hex Nut

- Duplex Steel S31803 Finished Hex Nut

- S32205 Duplex Steel Finished Hex Nuts

- UNS S31803 Finished Hex Nuts

- UNS S32205 Finish Hex Nuts

- Duplex Steel 2205 Finished Hex Nut

- 1.4462 Finished Hex Nut

- SAF 2205 Finished Hex Nut

Duplex Steel S31803 Long Hex Nut

- Duplex Steel S31803 Long Hex Nut

- S32205 Duplex Steel Long Hex Nuts

- UNS S31803 Long Hex Nuts

- UNS S32205 M6 Hex Coupling Nuts

- Duplex Steel 2205 Long Hex Nut

- 1.4462 Coupling Hex Nut

- SAF 2205 Long Hex Nut

Duplex Steel S31803 Hexagonal Nylon Lock Nut

- Duplex Steel S31803 Hexagonal Nylon Lock Nut

- S32205 Duplex Steel Hex Nylon Lock Nuts

- UNS S31803 Hex Nylon Lock Nuts

- UNS S32205 Hex Nylock Nuts

- Duplex Steel 2205 Hex Nylon Lock Nut

- 1.4462 Hex Nylock Nut

- SAF 2205 Nylon Insert Hex Lock Nut

Duplex Steel S31803 Hex Flange Nut

- Duplex Steel S31803 Hex Flange Nut

- S32205 Duplex Steel Flange Hex Nuts

- UNS S31803 Flange Lock Nuts

- UNS S32205 Hex Flange Nuts

- Duplex Steel 2205 Hex Flange Nut

- 1.4462 Hex Flange Nut

- SAF 2205 Flange Hex Nuts

Duplex Steel S31803 Hex Jam Nut

- Duplex Steel S31803 Hex Jam Nut

- S32205 Duplex Steel Hexagon Jam Nuts

- UNS S31803 Heavy Hex Jam Nuts

- UNS S32205 Hex Jam Nuts

- Duplex Steel 2205 Hex Jam Nut

- 1.4462 Hex Jam Nut

- SAF 2205 Hex Jam Nuts

Duplex Steel S31803 Hex Nuts Available Standards

| DIN Nuts | Hexagon Nuts |

|---|---|

| Din 315 Nuts | DIN 934 |

| Din 431 Nuts | BS 1768 |

| Din 555 Nuts | BS 1769 |

| Din 557 Nuts | BS 1083 |

| Din 562 Nuts | BS 3692 |

| Din 582 Nuts | ISO 4032 |

| Din 934 Nuts | ISO 4033 |

| Din 936 Nuts | ANSI B18.2.2 |

| Din 1587 Nuts | |

| Din 6923 Nuts |

Other Related Products

Size Chart of Duplex Steel S31803 Hex Nuts

| Nut Size (mm) |

Diameter* (mm) |

Height (mm) |

||

|---|---|---|---|---|

| Hex Nut | Jam Nut | Nylock Nut | ||

| 2 | 4 | 1.6 | 1.2 | |

| 2.5 | 5 | 2 | 1.6 | |

| 3 | 5.5 | 2.4 | 1.8 | 4 |

| 4 | 7 | 3.2 | 2.2 | 5 |

| 5 | 8 | 4 | 2.7 | 5 |

| 6 | 10 | 5 | 3.2 | 6 |

| 7 | 11 | 5.5 | 3.5 | |

| 8 | 13 | 6.5 | 4 | 8 |

| 10 | 17 | 8 | 5 | 10 |

| 12 | 19 | 10 | 6 | 12 |

| 14 | 22 | 11 | 7 | 14 |

| 16 | 24 | 13 | 8 | 16 |

| 18 | 27 | 15 | 9 | 18.5 |

| 20 | 30 | 16 | 10 | 20 |

| * This is the diameter across the flats. It is also the size of wrench to use. | ||||

Dimensions of Duplex Stainless Steel 2205 Hex Nuts

| DIA | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 |

| Pitch | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 |

| Across Flat (S) Max Min | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |

| Thickness (M) MaxMin | 3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 18 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 |

| 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 16.9 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | |

| Across corners (E) Min | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.35 | 26.75 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 |

| Minor Dia at thread (min) | 3.242 | 4.134 | 4.917 | 6.647 | 8.376 | 10.106 | 11.835 | 13.835 | 15.294 | 17.294 | 19.294 | 20.752 | 23.752 | 26.211 | 29.211 | 31.67 | 34.67 | 37.129 | 40.129 | 42.587 | 46.587 |

| Minor Dia at thread (max) | 3.422 | 4.334 | 5.153 | 6.912 | 8.676 | 10.441 | 12.210 | 14.210 | 15.744 | 17.774 | 19.774 | 21.252 | 24.252 | 26.771 | 29.771 | 32.27 | 35.27 | 37.799 | 40.799 | 43.297 | 47.297 |

Hex Nuts In mm Threads To IS 6623-1985 GRADES 8S & 10S

All dimensions in mm

| DIA | M16 | M20 | M22 | M24 | M27 | M30 | M36 |

| Pitch | 2 | 2.5 | 2.5 | 3 | 3 | 3.5 | 4 |

| Head Across Flat (B) Min | 26.16 | 33 | 35 | 40 | 45 | 49 | 58.8 |

| Head Across Flat (B) Max | 27 | 34 | 36 | 41 | 46 | 50 | 60 |

| Height (H) Min Max | 16.4 | 19.4 | 22.3 | 22.9 | 26.3 | 29.1 | 35 |

| 17.1 | 20.7 | 23.6 | 24.2 | 27.6 | 30.7 | 36.6 | |

| Across corners C min | 29.56 | 37.29 | 39.55 | 45.20 | 50.85 | 55.37 | 66.44 |

| Minor Dia at thread (min) | 14.235 | 17.694 | 19.694 | 21.202 | 24.252 | 26.761 | 32.270 |

| Minor Dia at thread (max) | 14.610 | 18.144 | 20.144 | 21.702 | 24.752 | 27.321 | 32.870 |

Dimensions of Duplex Steel S31803 Heavy Hex Nuts

| UNC Nut N/B | Max Across Corners | Min Across Corners | Max Thickness | Min Thickness | Max Across Flats | Max Across Flats |

|---|---|---|---|---|---|---|

| 3/8 | 20.2 | 19.4 | 9.6 | 8.7 | 17.5 | 17 |

| 7/16 | 22 | 21.1 | 11.2 | 10.2 | 19 | 18.5 |

| 1/2 | 25.6 | 24.6 | 12.8 | 11.8 | 22.2 | 21.6 |

| 9/16 | 27.5 | 26.3 | 14.4 | 13.4 | 23.8 | 23.1 |

| 5/8 | 31.2 | 29.8 | 16 | 14.9 | 27 | 26.2 |

| 3/4 | 36.7 | 35.1 | 19.3 | 18 | 31.8 | 30.8 |

| 7/8 | 42.2 | 40.4 | 22.5 | 21.2 | 36.5 | 35.4 |

| 1 | 47.7 | 45.6 | 25.7 | 24.3 | 41.3 | 40 |

| 1 1/8 | 53.2 | 50.8 | 28.9 | 27.4 | 46 | 44.6 |

| 1 1/4 | 58.6 | 56.1 | 31.8 | 30.1 | 50.8 | 49.2 |

| 1 3/8 | 64.2 | 61.4 | 35 | 33.3 | 55.6 | 53.8 |

| 1 1/2 | 69.6 | 66.6 | 38.2 | 36.4 | 60.3 | 58.4 |

| 1 5/8 | 75.2 | 71.8 | 41.5 | 39.5 | 65.1 | 63 |

| 1 3/4 | 80.6 | 77.1 | 44.7 | 42.6 | 69.9 | 67.6 |

| 1 7/8 | 86.2 | 82.3 | 47.9 | 45.8 | 74.6 | 72.2 |

| 2 | 91.6 | 87.6 | 51.1 | 48.9 | 79.4 | 76.8 |

| 2 1/4 | 102.6 | 98.1 | 57.2 | 54.7 | 88.9 | 86.1 |

| 2 1/2 | 113.6 | 108.6 | 63.6 | 61 | 98.4 | 95.2 |

| 2 3/4 | 124.6 | 119.1 | 70.1 | 67.2 | 108 | 104.4 |

| 3 | 135.6 | 129.6 | 76.5 | 73.5 | 117.5 | 113.7 |

Weight Chart Of Duplex Steel 2205 Hex Nuts

| Size | Finished Hex | Heavy Hex | Finished Jam | Heavy Hex Jam | Square | Heavy Square |

|---|---|---|---|---|---|---|

| 1/2″ | 3.750 | 6.540 | 2.620 | 4.000 | 5.780 | 7.870 |

| 5/8″ | 7.330 | 11.900 | 4.930 | 6.960 | 10.800 | 14.300 |

| 3/4″ | 11.900 | 19.300 | 7.700 | 11.000 | 15.400 | 23.500 |

| 7/8″ | 19.000 | 29.700 | 12.000 | 16.700 | 24.500 | 36.200 |

| 1″ | 28.300 | 42.500 | 17.600 | 23.500 | 36.300 | 51.500 |

| 1-1/8″ | 40.300 | 59.200 | 24.700 | 32.400 | 52.500 | 72.400 |

| 1-1/4″ | 54.300 | 78.600 | 36.100 | 45.800 | 70.600 | 95.500 |

| 1-3/8″ | 73.000 | 102.000 | 47.900 | 59.300 | 94.500 | 125.000 |

| 1-1/2″ | 94.300 | 131.000 | 60.900 | 74.800 | 122.000 | 161.000 |

| 1-5/8″ | 162.000 | 91.600 | ||||

| 1-3/4″ | 151.000 | 204.000 | 100.000 | 114.000 | ||

| 1-7/8″ | 241.000 | 134.000 | ||||

| 2″ | 224.000 | 299.000 | 140.000 | 165.000 | ||

| 2-1/4″ | 419.000 | 227.000 | ||||

| 2-1/2″ | 564.000 | 332.000 | ||||

| 2-3/4″ | 738.000 | 429.000 | ||||

| 3″ | 950.000 | 545.000 | ||||

| 3-1/4″ | 1194.000 | 651.000 | ||||

| 3-1/2″ | 1526.000 | 851.000 | ||||

| 3-3/4″ | 1812.000 | 1005.000 | ||||

| 4″ | 2180.000 | 1200.000 |

Test Certificates Of Duplex Steel S31803 Hex Nuts

- Mill Test Report

- Raw Materials Certificate

- EN 10204/3.1B

- Third Party Inspection Report

- 100% Radiography Test Report

Chemical Composition of Duplex Steel S31803 Hex Nuts

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 – 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Mechanical Properties of Duplex Steel S31803 Hex Nuts

| Tensile Strength, ksi | 0.2% Yield Strength, ksi | Elongation, % | Hardness [HRC] |

|---|---|---|---|

| 90 min | 65 min | 25 min | 293 max |

Duplex Steel S31803 Hex Nuts Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment