Alloy 20 Needle Valve

Alloy 20 Integral Bonnet Needle Valve, Carpenter 20 High Pressure Needle Valve Manufacturer, Suppliers of Alloy 20 Hydraulic Needle Valve, Alloy 20 Compression Needle Valve, Inconel® alloy 20 Gauge Valve At Factory Price In India.

Vintex Steel & Engg. Co. is an exporter of Alloy 20 Needle Valves & Gauge Valves, which gives extended ductility in choppy segments. Content of these valves is comparable in molybdenum, chromium and nickel to a few austenitic steels. It is well-matched for deplete to a temperature of as much as 1500 Degree F for unremitting carrier in oxidizing atmospheres and round 1300 Degree F in corrosive atmosphere (including fuelling turbines). As the industry is having good years of working experience in the same sector since a long time, they are easily and effectively able to deal with the large numbers of clients on daily basis and take the order in bulk and perfectly fulfill all the desires of every buyer.

Alloy 20 Miniature Needle Valve, 1/2 Inch Alloy 20 Needle Valve, Alloy 20 Instrumentation Needle Valve, Inconel® alloy 20 Miniature Needle Valve Stockist, DIN 2.4660 Hex Needle Valve Supplier, 2.4660 Needle Valve, UNS N08020 Gauge Valve, UNS N08020 Forged Needle Valve, Carpenter 20 Panel Mount Needle Valve, Nickel Alloy 20 Union Bonnet Needle Valve Manufacturer In India.

- Material Specification Chart Of Alloy 20 Needle & Gauge Valve

- Alloy 20 Needle & Gauge Valve Equivalent Grade

- Most Commonly used Alloy 20 Needle & Gauge Valve Types

- Dimension Chart Of Alloy 20 Needle & Gauge Valve

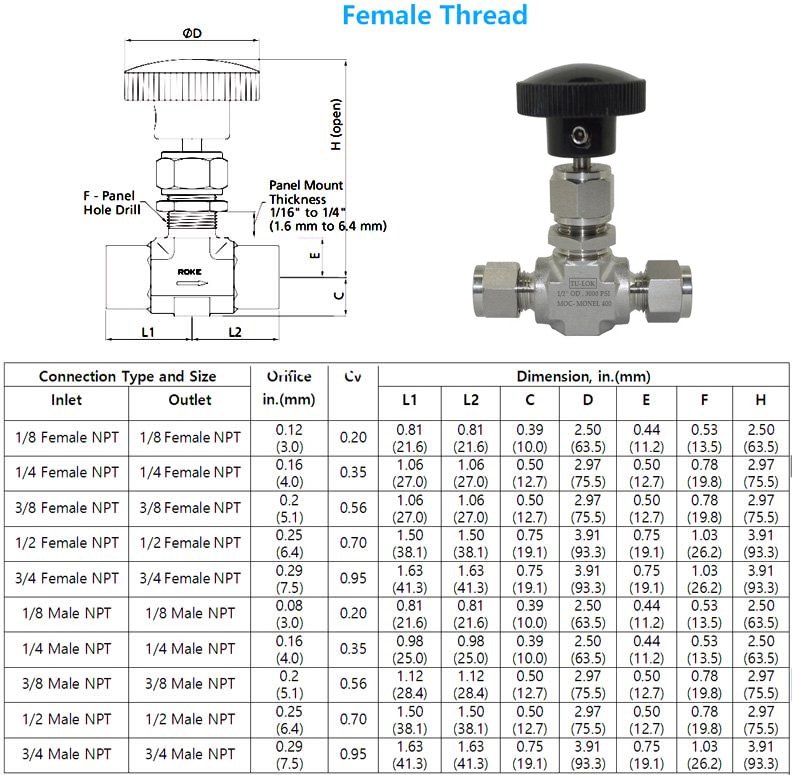

- Alloy 20 Female Thread Needle Valve Dimensions Chart

- Stock List Of Alloy 20 Needle & Gauge Valve

- Chemical Composition of Alloy 20 Needle & Gauge Valve

- Mechanical Properties of Alloy 20 Needle & Gauge Valve

- Alloy 20 Needle & Gauge Valve Uses and Application

- Alloy 20 Needle & Gauge Valve Export Countries

Alloy 20 High Pressure Needle & Gauge Valve are general function grade that is frequently supplied in the toughened but still machine able form for functions where elevated strength and restrained heat and corrosion resistance are being needed. It is utilized in plenty of affordable temperature and pressure packages in jet engines, like low stress turbines, shafts, afterburner elements and compressors. WNR 2.4660 Gauge Valves is frequently used for hydrocarbon and chemical processing machinery, marine engineering, shafts, fittings, valves, pumps, fasteners, and warmth exchangers. It is pretty identified for its corrosion resistant and extended energy properties. Conventional machining strategies used for iron primarily based totally alloys can be used right here in such valves. Alloy 20Cb3 Needle Valves has extraordinary corrosion resistance collectively with elevated energy and hardness. Additional utility region of these valves is in marine environments and different non-oxidizing chloride solutions.

Material Specification Chart Of Alloy 20 Needle & Gauge Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Alloy 20 Needle & Gauge Valve Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo |

Most Commonly used Alloy 20 Needle & Gauge Valve Types

Alloy 20 Screwed End Needle Valve

Alloy 20 Tube End Needle Valve

Alloy 20 Socket Weld Needle Valve

Alloy 20 Angle Needle Valve

Alloy 20 Hexagonal Needle Valve

Alloy 20 3 Way Needle Valve

Alloy 20 Union Bonnet Needle Valve

Alloy 20 Panel Mounted Needle Valve

Alloy 20 Forged Needle Valve

Alloy 20 Miniature Needle Valve

Alloy 20 High Pressure Needle Valve

Alloy 20 Bar Stock Needle Valve

Dimension Chart Of Alloy 20 Needle & Gauge Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Alloy 20 Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of Alloy 20 Needle & Gauge Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Alloy 20 Needle & Gauge Valve

- Alloy 20 Gauge Valve

- Inconel® alloy 20 Female Thread Needle Valve

- Alloy 20 Screwed End Needle Valve Exporter

- Alloy 20 High Pressure Needle Valve

- Alloy 20 Flow Control Needle Valves

- Carpenter 20 1/4 Needle Valve

- Alloy 20 Hydraulic Needle Valve Supplier

- Alloy 20 1rs4 Needle Valve

- DIN 2.4660 Threaded Needle Valve

- Inconel® alloy 20 Angle Needle Valve

- Alloy 20 Integral Bonnet Needle Valve Stockist

- Inconel® alloy 20 Compression Needle Valve

- Carpenter 20 Needle Valve

- Alloy 20 1/2 Inch Needle Valve

- Carpenter 20 3 Way Needle Valve

- UNS N08020 Socket Weld End Needle Valve

- Alloy 20 Flanged Needle Valve

- UNS N08020 Gauge Valve

- Nickel Alloy 20 Forged Needle Valve Distributor

- Alloy 20 Male Needle Valve Manufacturer

- UNS N08020 Female Male Needle Valves

- Inconel® alloy 20 90 Deg Angled Needle Valve

- Carpenter 20 Instrumentation Gauge Valve

- Alloy 20 Straight Needle Valve

- Alloy 20 Hex Needle Valves

- Inconel® alloy 20 Miniature Needle Valve

- DIN 2.4660 Bar Stock Needle Valve

- Inconel® alloy 20 Round Body Needle Valve

- Alloy 20 Industrial Needle Valve Price

- Alloy 20 Panel Mount Needle Valve

- Carpenter 20 Screwed Bonnet Valve

- Alloy 20 Multi Port Gauge Needle Valve

- Alloy 20 Union Bonnet Needle Valve

- Alloy 20 Single Port Gauge Needle Valve Dealer

Chemical Composition of Alloy 20 Needle & Gauge Valve

| Grade | Ni | C | Mn | P | S | Si | Cr | Nb | Mo | Cu |

| Alloy 20 | 32 – 38 | 0.02 max | 1 – 2 | 0.02 max | 0.005 max | 0.7 max | 19 – 21 | 0.1 – 0.3 | 2 – 3 | 3 – 4 |

Mechanical Properties of Alloy 20 Needle & Gauge Valve

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Alloy 20 Needle & Gauge Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment