Alloy 20 Tube Plug

Alloy 20 Tube Plug, Alloy 20 Header Plug, Suppliers of Incoloy® alloy 20 Heat Exchanger Tube Plug, Alloy 20 Tapered Tube Plug, Carpenter 20 Two-Piece Tube Plug Manufacturer India, Alloy 20 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular distributing unit of Alloy 20 Tube Plug, which is normally utilized in textile, chemical and pulp paper equipment, for corrosion resistance.

It is regularly used as a fabric of production as much as approximately 1500 Degree F. It has a better carbon content material making the metallic greater appropriate to be used in packages in which increased temperatures are present. However, a knowledge of the attributes gives a great base for evaluating contributors of the austenitic own circle of relatives of steels and a sensible base for figuring out the appropriateness of metallic in a given application. UNS N08020 Tube Plug additionally has an excessive diploma of ductility, great drawing, forming and spinning properties. It has some of world-magnificence attributes to offer like longer life, excessive finish, reliable, etc.

Alloy 20 Boiler Tube Plug, 2.4660 Tube Plug, Inconel® Alloy 20 High Pressure Tube Plug, UNS N08020 Tube Plug, Alloy 20 One-Piece Tube Plug Stockist, DIN 2.4660 Condenser Tube Plug Supplier, Nickel Alloy 20 Expansion Tube Plug, UNS N08020 Metal Tapered Tube Plugs Manufacturer In India.

- Material Specification Chart Of Alloy 20 Tube Plug

- Alloy 20 Tube Plug Equivalent Grade

- Most Commonly used Alloy 20 Tube Plug Types

- Alloy 20 Tube Plug Sizes

- Alloy 20 Threaded Tapered Plug Sizes

- Alloy 20 Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy 20 Tube Plug

- Chemical Composition of Alloy 20 Tube Plug

- Mechanical Properties of Alloy 20 Tube Plug

- Alloy 20 Tube Plug Uses and Application

- Alloy 20 Tube Plug Export Countries

It is normally utilized in fertilizer and acid manufacture equipment, application scrubber assemblages, etc. It acts nicely than different austenitic alloys due to the advanced alloying of molybdenum and nickel. Using superior and complicated strategies of manufacture, this presented array is industrialized via way of means of keeping great grade contributions below the control of finished workers. On the opposite hand, oxyacetylene welding isn’t always selected for this alloy. WNR 2.4660 Tube Plug may be welded via way of means of the usage of maximum of the fusion and resistance approaches. It has some of notable capabilities to offer like effective, reliable, rugged and greater.

It is a not unusual place reason austenitic alloy this is stabilised in contradiction of carbide precipitation and supposed to paintings within the carbide precipitation temperature. They are used for the purpose that they’re now no longer diffused to intergranular corrosion after heating within the carbide precipitation. It is an intermediate carbon austenitic stainless metallic, for hovering temp packages like warmth remedy equipment and furnace components. Alloy 20Cb3 Tube Plug has notable resistance to oxidation below non-stop temp to 2000 Deg F. It has an advanced content material of carbon making the alloy greater suitable to be used in features in which excessive temperatures are in attendance.

Material Specification Chart Of Alloy 20 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Alloy 20 Tube Plug Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo |

Most Commonly used Alloy 20 Tube Plug Types

Alloy 20 Tapered Tube Plug

Alloy 20 Heat Exchanger Tube Plug

Alloy 20 Threaded Tapered Plug

Alloy 20 One-Piece Tube Plug

Alloy 20 Two-Piece Tube Plug

Alloy 20 Metal Tapered Tube Plug

Alloy 20 Expandable Tube Plug

Alloy 20 Boiler Tube Plug

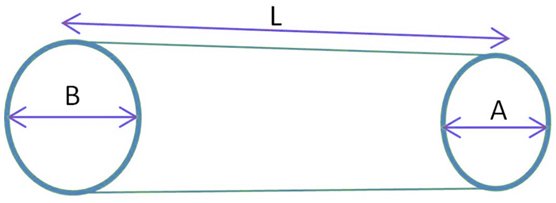

Alloy 20 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy 20 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Alloy 20 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Alloy 20 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy 20 Tube Plug

| Grade | Ni | C | Mn | P | S | Si | Cr | Nb | Mo | Cu |

| Alloy 20 | 32 – 38 | 0.02 max | 1 – 2 | 0.02 max | 0.005 max | 0.7 max | 19 – 21 | 0.1 – 0.3 | 2 – 3 | 3 – 4 |

Mechanical Properties of Alloy 20 Tube Plug

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Alloy 20 | 8.1 g/cm3 | 1443 °C (2430 °F) | Psi -80,000, MPa -551 | Psi – 35,000, MPa – 241 | 30 % |

Alloy 20 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment