ASME SA 210 Carbon Steel Tube Plug

Carbon Steel SA 210 Header Plug, Suppliers of Carbon Steel SA 210 Heat Exchanger Tube Plug, Carbon Steel A210 Gr A1 Tapered Tube Plug, ASME SA 210 Carbon Steel Two-Piece Tube Plug Manufacturer India, Carbon Steel A210 Grade A1 Tube Plug, CS SA 210 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a widely known distributor of Carbon Steel ASME SA 210 Tube Plug, which is as nicely famous notable for its standard corrosion resistance.

Characteristics of those merchandise are: Dimensional accuracy, Sturdy construction, Rust evidence and so on. It is excessive on requirement within the enterprise for its notable finish. It is synthetic through the use of first-rate grade of metallic and cutting-edge approaches in line by way of nicely-described enterprise norms and standards. Carbon Steel ASTM A210 Tube Plug are being disbursed and synthetic through the corporation which might be factory-crafted from the greatest great of uncooked metallic if you want to they may be extraordinarily hard-carrying and feature notably lengthy running life. It is specifically utilized in packages that encompass intermittent and non-stop carrier temperatures within the carbide precipitation variety of 800 Deg F to 1500 Degr F.

Carbon Steel A210 Gr A1 Tube Plug, ASTM A210 Gr C Carbon Steel One-Piece Tube Plug Stockist, ASME SA 210 Carbon Steel Expansion Tube Plug, CS A210 Grade C Condenser Tube Plug Supplier, CS SA 210 High Pressure Tube Plug, Carbon Steel SA 210 Boiler Tube Plug, ASME SA 210 CS Metal Tapered Tube Plugs Manufacturer In India.

- Material Specification Chart Of ASME SA 210 Carbon Steel Tube Plug

- Most Commonly used ASME SA 210 Carbon Steel Tube Plug Types

- Carbon Steel ASME SA 210 Tube Plug Sizes

- Carbon Steel ASME SA 210 Threaded Tapered Plug Sizes

- ASME SA 210 Carbon Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Carbon Steel SA 210 Tube Plug

- Chemical Composition of ASME SA 210 Carbon Steel Tube Plug

- Mechanical Properties of Carbon Steel SA 210 Tube Plug

- Carbon Steel ASME SA 210 Tube Plug Uses and Application

- ASME SA 210 Carbon Steel Tube Plug Export Countries

It is typically utilized in acid and fertilizer manufacturing equipment, application scrubber assemblies, etc. It covers hovering quantities of different elements, including nickel and molybdenum. ASTM A210 Carbon Steel Tube Plug is ferrite metallic that gives proper mechanical residences and excessive-temperature corrosion resistance. It is standard-cause martensitic stainless steels containing 11.five percentage chromium, which give proper corrosion resistance residences. It is an excessive-carbon metallic with a minimal chromium content material of 12 percentage. They are typically utilized in multiplied temperature chemical manner warmness exchanger tubes, and multiplied temperature steam carrier.

It is non-hardenable metallic containing instantly chromium, and belongs to the ferrite institution of steels. But, the hardenability of it could be decreased through the usage of non-stop optimistic feeds and leisurely speeds. ASME SA 210 Carbon Steel Tube Plug are specifically utilized in multiplied temperature atmospheres wherein resistance to sensitization is important, sequentially stopping intergranualr corrosion at inferior levels. It gives advanced pressure ruptures and creep residences which might also additionally likely as nicely be nicely-thought-out for exposures wherein intergranular and sensitization corrosion are concerns. It has notable welding features; and post-weld annealing isn’t always generally important to reinstate its notable overall performance in an intensive variety of corrosive environments.

Material Specification Chart Of ASME SA 210 Carbon Steel Tube Plug

| Standard | ASTM A210 / ASME SA210 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Most Commonly used ASME SA 210 Carbon Steel Tube Plug Types

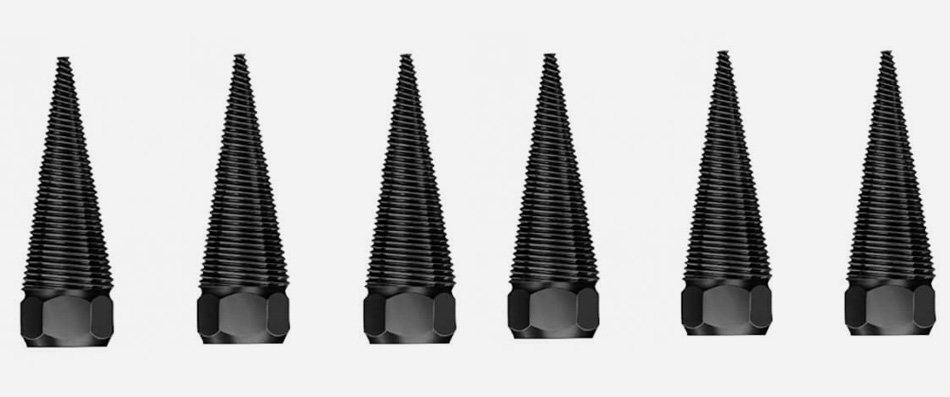

Carbon Steel SA 210 Tapered Tube Plug

Carbon Steel SA 210 Heat Exchanger Tube Plug

Carbon Steel SA 210 Threaded Tapered Plug

Carbon Steel SA 210 One-Piece Tube Plug

Carbon Steel SA 210 Two-Piece Tube Plug

Carbon Steel SA 210 Metal Tapered Tube Plug

Carbon Steel SA 210 Expandable Tube Plug

Carbon Steel SA 210 Boiler Tube Plug

Carbon Steel ASME SA 210 Tube Plug Sizes

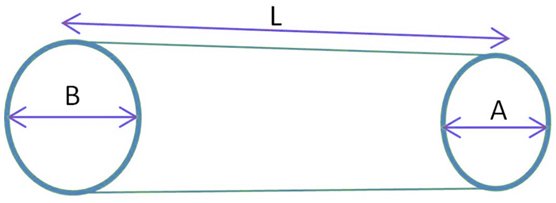

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Carbon Steel ASME SA 210 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASME SA 210 Carbon Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASME SA 210 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASME SA 210 Carbon Steel Tube Plug

| Element | Carbon | Manganese | Phosphorus | Sulfur |

| Grade A1 | 0.27 | 0.93 | 0.035 | 0.04 |

| Grade C | 0.35 | 0.29-1.06 | 0.035 | 0.035 |

Mechanical Properties of Carbon Steel SA 210 Tube Plug

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

| A1 | ≥415 | ≥255 | ≥30 |

| C | ≥485 | ≥275 | ≥30 |

Carbon Steel ASME SA 210 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment