ASTM A182 Alloy Steel F22 Tube Plug

Suppliers of Alloy Steel F22 Heat Exchanger Tube Plug, Alloy Steel F22 Header Plug, Alloy Steel A182 F22 Tapered Tube Plug, Alloy Steel F22 Tube Plug, ASTM A182 F22 Alloy Steel Two-Piece Tube Plug Manufacturer India, Chrome Moly F22 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular trader of Alloy Steel ASTM A182 F22 Tube Plug, which are used as had to hold the top- or bottom-of-pipe level.

They are recounted for max performance, excessive tensile strength, corrosion & temperature resistant and longer provider life. It is an alloy without a bore and is used to close off a piping gadget or vessel opening. It additionally allows smooth get admission to vessels or piping structures for inspection purposes. Alloy Steel ASME SA 182 F22 Tube Plug are utilized in many, unique fields, which includes the transport (pipelines, ships) of petroleum, gas, water, etc. It is used to seal the give up of pipes structures and save you glide, making it smooth to behaviour stress tests. They are smooth to paintings round as they permit handy get admission to pipes.

ASME SA 182 F22 Alloy Steel One-Piece Tube Plug Stockist, UNS K21590 Metal Tapered Tube Plugs, Alloy Steel ASTM A182 F22 Boiler Tube Plug, ASTM A182 F22 Alloy Steel Expansion Tube Plug, CrMo A182 F22 High Pressure Tube Plug, DIN 1.7380 Condenser Tube Plug Supplier, 1.7380 Tube Plug Manufacturer In India.

- Material Specification Chart Of ASTM A182 Alloy Steel F22 Tube Plug

- ASTM A182 Alloy Steel F22 Tube Plug Equivalent Grade

- Most Commonly used ASTM A182 Alloy Steel F22 Tube Plug Types

- Alloy Steel ASTM A182 F22 Tube Plug Sizes

- Alloy Steel ASTM A182 F22 Threaded Tapered Plug Sizes

- ASTM A182 F22 Alloy Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy Steel A182 F22 Tube Plug

- Chemical Composition of ASTM A182 F22 Alloy Steel Tube Plug

- Mechanical Properties of Alloy Steel A182 F22 Tube Plug

- Alloy Steel ASTM A182 F22 Tube Plug Uses and Application

- ASTM A182 Alloy Steel F22 Tube Plug Export Countries

It offer highest quality glide characteristics, without wallet or sharp corners, growing much less frictional resistance, no stress loss, much less turbulence, and so on. They are used anyplace liquids, gases, chemical compounds and different fluids are created, processed, transported, or used. It is frequently utilized in Sugar Industries, Chemical Plants, Fertilizer Plants, Pharmaceutical, Railway Coaches, Refrigeration, Metallurgical Industries, etc. ASTM A182 Alloy Steel F22 Tube Plug is likewise utilized in Oil & Gas Industries, Decorative, Dairies & Food Products, Instrumentation, Power Plants, Heat Exchangers, Pulp & Paper Mills. It is as properly utilized in Food Industries, Ornamental, Energy Industries, Ships, Fabrication, Automobile Industries, Sanitary / Plumbing, Boilers, Space, Textile Machinery.

It is made at once from a phase of seamless pipe material, through making use of warmness and stress to convert pipe at once into an elbow or different shape. It lets in for an alternate in pipe length to satisfy hydraulic glide necessities of the gadget or adapt to present piping of a unique length. ASME SA 182 Alloy Steel F22 Tube Plug are especially utilized in unique industries, which includes upstream (exploration and production), midstream (transportation through ships, pipeline, rail, trucks; garage and wholesale) and downstream (refining into fuels or chemical compounds; advertising and distribution).

Material Specification Chart Of ASTM A182 Alloy Steel F22 Tube Plug

| Standard | ASTM A182 / ASME SA182 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

ASTM A182 Alloy Steel F22 Tube Plug Equivalent Grade

| Grade | DIN | UNS | EN |

| ASTM A182 Gr. F22 | 1.7380 | K21590 | 2-1/4Cr-1/2Mo-Vd |

Most Commonly used ASTM A182 Alloy Steel F22 Tube Plug Types

Alloy Steel F22 Tapered Tube Plug

Alloy Steel F22 Heat Exchanger Tube Plug

Alloy Steel F22 Threaded Tapered Plug

Alloy Steel F22 One-Piece Tube Plug

Alloy Steel F22 Two-Piece Tube Plug

Alloy Steel F22 Metal Tapered Tube Plug

Alloy Steel F22 Expandable Tube Plug

Alloy Steel F22 Boiler Tube Plug

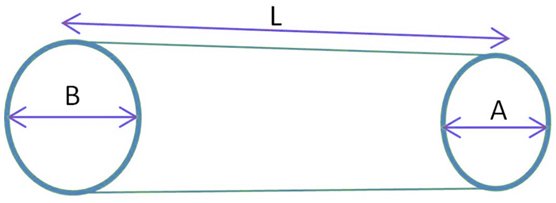

Alloy Steel ASTM A182 F22 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy Steel ASTM A182 F22 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A182 F22 Alloy Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A182 F22 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A182 F22 Alloy Steel Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F22 | 0.05 – 0.15 | 0.3 – 0.6 | 0.5 | 0.045 | 0.03 | 0.8 – 1.25 | 0.044 – 0.65 |

Mechanical Properties of Alloy Steel A182 F22 Tube Plug

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|

| 205 | 415 | 20 |

Alloy Steel ASTM A182 F22 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment