ASTM A182 Alloy Steel F5 Tube Plug

Alloy Steel F5 Header Plug, ASTM A182 F5 Alloy Steel Two-Piece Tube Plug Manufacturer India, Suppliers of Alloy Steel F5 Heat Exchanger Tube Plug, Alloy Steel F5 Tube Plug, Alloy Steel A182 F5 Tapered Tube Plug, Chrome Moly F5 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular manufacturer of Alloy Steel ASTM A182 F5 Tube Plug, which is normally utilized in textile, chemical and pulp paper machinery, for corrosion resistance.

It is the grade of preference for programs within the temperature variety of as much as approximately 900 Degree C, combining excessive energy, resistance to scaling and section balance with resistance to next aqueous corrosion. Alloy Steel ASME SA 182 F5 Tube Plug is a not unusual reason austenitic alloy this is stabilised in contradiction of carbide precipitation and meant to paintings within the carbide precipitation temperature that tiers from 800 Deg F to 1500 Deg F. It has the same corrosion resistance and excessive energy however could make sturdier welds due to the low content material of carbon.

ASTM A182 F5 Alloy Steel Expansion Tube Plug, DIN 1.7362 Condenser Tube Plug Supplier, ASME SA 182 F5 Alloy Steel One-Piece Tube Plug Stockist, CrMo A182 F5 High Pressure Tube Plug, Alloy Steel ASTM A182 F5 Boiler Tube Plug, UNS K41545 Metal Tapered Tube Plugs, 1.7362 Tube Plug Manufacturer In India.

- Material Specification Chart Of ASTM A182 Alloy Steel F5 Tube Plug

- ASTM A182 Alloy Steel F5 Tube Plug Equivalent Grade

- Most Commonly used ASTM A182 Alloy Steel F5 Tube Plug Types

- Alloy Steel ASTM A182 F5 Tube Plug Sizes

- Alloy Steel ASTM A182 F5 Threaded Tapered Plug Sizes

- ASTM A182 F5 Alloy Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy Steel A182 F5 Tube Plug

- Chemical Composition of ASTM A182 F5 Alloy Steel Tube Plug

- Mechanical Properties of Alloy Steel A182 F5 Tube Plug

- Alloy Steel ASTM A182 F5 Tube Plug Uses and Application

- ASTM A182 Alloy Steel F5 Tube Plug Export Countries

It is a better chromium, nickel and molybdenum model of stainless designed mainly for accelerated energy and corrosion resistance. It can normally be utilized in Heat exchangers, Fittings, Dyeing Machinery, Propeller shafts, Exterior Architectural components in Marine Coastal Parts. ASTM A182 Alloy Steel F5 Tube Plug is greater proof against standard corrosion and pitting/crevice corrosion than the traditional chromium-nickel austenitic steels. It presents advanced creep, tensile energy and strain to rupture at excessive temperatures. The decrease content material of carbon reduces deadly carbide precipitation due to welding. It differs in company of the aid of using having a decrease carbon content material in addition to barely decrease yield and tensile strengths.

We supply this to various clienteles counting fabricators of stress vessels, warmth exchangers and business boilers. It is absolutely an austenitic alloy, in which it’s far as properly alloyed by means of the aid of boron and nitrogen content material in it. This molybdenum offers higher basic corrosion resistant properties, mainly better resistance to pitting and crevice corrosion in chloride environments. ASME SA 182 Alloy Steel F5 Tube Plug is used for excessive temperature programs including furnace components and warmth remedy equipment. Cyclic paperwork condense its oxidation resistance, and a thoroughgoing purposeful temperature of 1900 Deg F is generally cautioned if biking is complicated.

Material Specification Chart Of ASTM A182 Alloy Steel F5 Tube Plug

| Standard | ASTM A182 / ASME SA182 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

ASTM A182 Alloy Steel F5 Tube Plug Equivalent Grade

| Grade | DIN | UNS | EN |

| ASTM A182 Gr. F5 | 1.7362 | K41545 | 5Cr-1/2Mo |

Most Commonly used ASTM A182 Alloy Steel F5 Tube Plug Types

Alloy Steel F5 Tapered Tube Plug

Alloy Steel F5 Heat Exchanger Tube Plug

Alloy Steel F5 Threaded Tapered Plug

Alloy Steel F5 One-Piece Tube Plug

Alloy Steel F5 Two-Piece Tube Plug

Alloy Steel F5 Metal Tapered Tube Plug

Alloy Steel F5 Expandable Tube Plug

Alloy Steel F5 Boiler Tube Plug

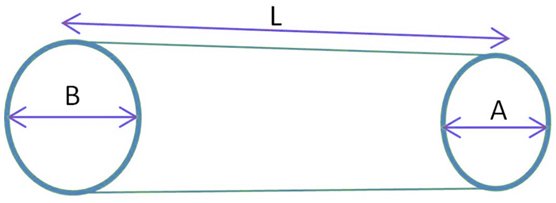

Alloy Steel ASTM A182 F5 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy Steel ASTM A182 F5 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A182 F5 Alloy Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A182 F5 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A182 F5 Alloy Steel Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F5 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4.0-6.0 | 0.44-0.65 |

Mechanical Properties of Alloy Steel A182 F5 Tube Plug

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|

| 275 | 485 | 20 |

Alloy Steel ASTM A182 F5 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment