ASTM A182 Alloy Steel F9 Tube Plug

Alloy Steel F9 Header Plug, ASTM A182 F9 Alloy Steel Two-Piece Tube Plug Manufacturer India, Alloy Steel F9 Tube Plug, Alloy Steel A182 F9 Tapered Tube Plug, Suppliers of Alloy Steel F9 Heat Exchanger Tube Plug, Chrome Moly F9 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular exporter of Alloy Steel ASTM A182 F9 Tube Plug, which provide enduring welded friends for important functions.

The cautiously managed chemical compositions offer a big variety of bloodless paintings hardenability, permitting them to in shape for numerous packages with the aid of using direct drawing without intermediate annealing. Alloy Steel ASME SA 182 F9 Tube Plug can be used for an extensive kind of domestic and industrial packages and famous tremendous corrosion resistance. It has an excessive ease of fabrication, tremendous formability, and extremely good strength. It has an advanced diploma of tremendous drawing, ductility, spinning and forming properties. Mechanical properties, chemical composition, corrosion / oxidation resistance and weldability provide the greatest flexible overall performance alloys at relatively low cost.

Alloy Steel ASTM A182 F9 Boiler Tube Plug, UNS K90941 Metal Tapered Tube Plugs, 1.7386 Tube Plug, ASME SA 182 F9 Alloy Steel One-Piece Tube Plug Stockist, DIN 1.7386 Condenser Tube Plug Supplier, ASTM A182 F9 Alloy Steel Expansion Tube Plug, CrMo A182 F9 High Pressure Tube Plug Manufacturer In India.

- Material Specification Chart Of ASTM A182 Alloy Steel F9 Tube Plug

- ASTM A182 Alloy Steel F9 Tube Plug Equivalent Grade

- Most Commonly used ASTM A182 Alloy Steel F9 Tube Plug Types

- Alloy Steel ASTM A182 F9 Tube Plug Sizes

- Alloy Steel ASTM A182 F9 Threaded Tapered Plug Sizes

- ASTM A182 F9 Alloy Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy Steel A182 F9 Tube Plug

- Chemical Composition of ASTM A182 F9 Alloy Steel Tube Plug

- Mechanical Properties of Alloy Steel A182 F9 Tube Plug

- Alloy Steel ASTM A182 F9 Tube Plug Uses and Application

- ASTM A182 Alloy Steel F9 Tube Plug Export Countries

It has tremendous in an extensive variety of atmospheric environments and plenty of corrosive media. It has a few tremendous functions to provide which include Uniform thickness, Longer provider life, Corrosion, chemical and temperature resistance, etc. ASTM A182 Alloy Steel F9 Tube Plug are fairly valued within the marketplace because of easy texture, excessive tensile strength, correct dimensions and durability. It has a few tremendous functions which include sturdier in nature, nice finish, best checked, rust evidence and more. They are in particular synthetic the use of most efficient grade metal at our sound production facility. They are utilized in numerous engineering purposes, fencing, scaffolding, line pipes etc.

It refers to an electron beam welding, the usage of excessive-pace motion of the electron beam directed effect kinetic strength is transformed to warmth the work piece in order that the leaving the melt, the formation of the weld. It permits the handy disconnection of pipes for protection or fixture replacement. ASME SA 182 Alloy Steel F9 Tube Plug calls for solvent welding, soldering or rotation (threaded couplings), and a union permits smooth connection and disconnection. There are some of plug types: mechanical, pneumatic-disk, single-length pneumatic rubber, multi-length pneumatic and flow-through, and excessive-pressure. It has complete strains of aid and forging machinery, counting the most modern in die sinking equipment.

Material Specification Chart Of ASTM A182 Alloy Steel F9 Tube Plug

| Standard | ASTM A182 / ASME SA182 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

ASTM A182 Alloy Steel F9 Tube Plug Equivalent Grade

| Grade | DIN | UNS | EN |

| ASTM A182 Gr. F9 | 1.7386 | K90941 | 9Cr-1Mo |

Most Commonly used ASTM A182 Alloy Steel F9 Tube Plug Types

Alloy Steel F9 Tapered Tube Plug

Alloy Steel F9 Heat Exchanger Tube Plug

Alloy Steel F9 Threaded Tapered Plug

Alloy Steel F9 One-Piece Tube Plug

Alloy Steel F9 Two-Piece Tube Plug

Alloy Steel F9 Metal Tapered Tube Plug

Alloy Steel F9 Expandable Tube Plug

Alloy Steel F9 Boiler Tube Plug

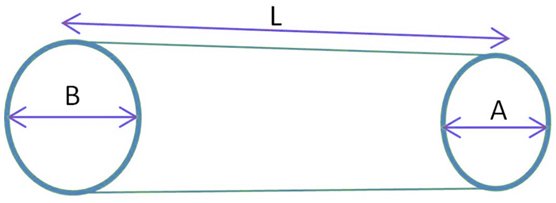

Alloy Steel ASTM A182 F9 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy Steel ASTM A182 F9 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A182 F9 Alloy Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A182 F9 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A182 F9 Alloy Steel Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F9 | 0.15 max | 0.3-0.6 | 0.5 – 1 | 0.03 | 0.03 | 8 – 10 | 0.9 – 1.1 |

Mechanical Properties of Alloy Steel A182 F9 Tube Plug

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|

| 380 | 585 | 20 |

Alloy Steel ASTM A182 F9 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment