ASTM A182 Alloy Steel F91 Tube Plug

Alloy Steel A182 F91 Tapered Tube Plug, Suppliers of Alloy Steel F91 Heat Exchanger Tube Plug, ASTM A182 F91 Alloy Steel Two-Piece Tube Plug Manufacturer India, Alloy Steel F91 Header Plug, Alloy Steel F91 Tube Plug, Chrome Moly F91 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular distributor of Alloy Steel ASTM A182 F91 Tube Plug, which has first-rate energy to weight ratio of any corrosion resistant material.

They are recognized for proof against fashionable corrosion, crevice corrosion, inter granular attack, pitting and strain corrosion cracking. It then come to be a part of a machine for transporting fluids (oil, gas, steam, chemicals, and so on) in a secure and green manner, over brief or lengthy distances. Alloy Steel ASME SA 182 F91 Tube Plug is designed to be welded at its end(s) to attach pipe(s) collectively and permit alternate in course or pipe diameter, or branching or ending. It agree to applicable cloth and dimensional specs and may be furnished whole with cloth certificates. They are available in some of qualities, diameters and wall thicknesses of the completed steels.

Alloy Steel A182 F91 Tapered Tube Plug, Suppliers of Alloy Steel F91 Heat Exchanger Tube Plug, ASTM A182 F91 Alloy Steel Two-Piece Tube Plug Manufacturer India, Alloy Steel F91 Header Plug, Alloy Steel F91 Tube Plug, Chrome Moly F91 Tube Plug At Factory Price In India.

- Material Specification Chart Of ASTM A182 Alloy Steel F91 Tube Plug

- ASTM A182 Alloy Steel F91 Tube Plug Equivalent Grade

- Most Commonly used ASTM A182 Alloy Steel F91 Tube Plug Types

- Alloy Steel ASTM A182 F91 Tube Plug Sizes

- Alloy Steel ASTM A182 F91 Threaded Tapered Plug Sizes

- ASTM A182 F91 Alloy Steel Two-Piece Metal Tube Plug Sizes

- Stock List Of Alloy Steel A182 F91 Tube Plug

- Chemical Composition of ASTM A182 F91 Alloy Steel Tube Plug

- Mechanical Properties of Alloy Steel A182 F91 Tube Plug

- Alloy Steel ASTM A182 F91 Tube Plug Uses and Application

- ASTM A182 Alloy Steel F91 Tube Plug Export Countries

They are extraordinarily preferred within the enterprise due to easy texture, specific dimensions, excessive tensile efficiency and sturdiness. It has a few extraordinary capabilities including sturdier in nature, first-rate finish, exceptional checked, rust evidence and more. ASTM A182 Alloy Steel F91 Tube Plug are made-up via way of means of our professionals in obedience via worldwide exceptional requirements and via way of means of the usage of advanced grade aspect involvements. It additionally has a few first rate capabilities to provide including longer carrier life, uniform thickness, corrosion, temperature and chemical resistance, etc.

They are appreciably used for warmth switch in technique gadget like boilers, extremely good heaters, warmness exchangers and condensers. It is completely proof against corrosion at temperatures as much as six hundred Degree F, rendering it best for a lot of marine uses. It is regularly used for a number of programs within the aerospace, marine, electricity technology and offshore industries. ASME SA 182 Alloy Steel F91 Tube Plug is designed to characteristic excessive energy, resistance to pitting, strain corrosion cracking, erosion corrosion and corrosion fatigue, crevice corrosion and sturdy weldability. It has a few extraordinary capabilities to provide including abrasion resistant nature, smooth to install, leakage loose connection and more.

Material Specification Chart Of ASTM A182 Alloy Steel F91 Tube Plug

| Standard | ASTM A182 / ASME SA182 |

|---|---|

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

ASTM A182 Alloy Steel F91 Tube Plug Equivalent Grade

| Grade | DIN | UNS | EN |

| ASTM A182 Gr. F91 | 1.4903 | K90901 | 9Cr-1Mo-V |

Most Commonly used ASTM A182 Alloy Steel F91 Tube Plug Types

Alloy Steel F91 Tapered Tube Plug

Alloy Steel F91 Heat Exchanger Tube Plug

Alloy Steel F91 Threaded Tapered Plug

Alloy Steel F91 One-Piece Tube Plug

Alloy Steel F91 Two-Piece Tube Plug

Alloy Steel F91 Metal Tapered Tube Plug

Alloy Steel F91 Expandable Tube Plug

Alloy Steel F91 Boiler Tube Plug

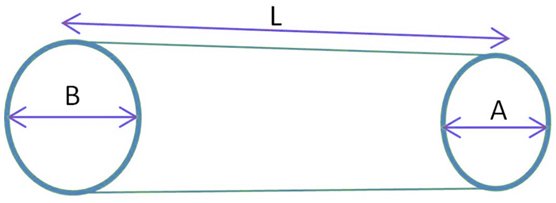

Alloy Steel ASTM A182 F91 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Alloy Steel ASTM A182 F91 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

ASTM A182 F91 Alloy Steel Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of ASTM A182 F91 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of ASTM A182 F91 Alloy Steel Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo |

| ASTM A182 F91 | 0.08 – 0.12 | 0.3 – 0.6 | 0.5 | 0.01 | 0.02 | 8.5 – 9.5 | 0.85 – 1.05 |

Mechanical Properties of Alloy Steel A182 F91 Tube Plug

| Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

|---|---|---|

| 415 | 585 | 20 |

Alloy Steel ASTM A182 F91 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment