Cupro Nickel 70/30 Tube Plug

CuNi 70/30 Tapered Tube Plug, Cu-Ni 70/30 Header Plug, 70/30 Copper Nickel Two-Piece Tube Plug Manufacturer India, Suppliers of Copper Nickel 70/30 Heat Exchanger Tube Plug, Cupro Nickel 70/30 Tube Plug, Cupro Nickel 70/30 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a widely known seller of Copper Nickel 70 / 30 Tube Plug, which are designed for expanded temperature service.

It is typically utilized in petrochemical and chemical technique machinery, condensers in fossil, pulp and paper industrialized, and nuclear power-pushed era stations. Machining of this alloy desires low speeds and non-stop feeds to lower its propensity to paintings reinforce. Cupronickel 70 / 30 Tube Plug has a better corrosion resistance in advanced programs wherein it’s far looked-for to lower contagion to a least. It is non-magnetic within the hardened scenario however can also additionally possibly come to be magnetic to a point due to welding. The molybdenum content material gives stepped forward corrosion resistant attributes, especially better resistance to crevice and pitting corrosion in chloride atmospheres.

Cu-Ni 70/30 One-Piece Tube Plug Stockist, UNS C71500 Metal Tapered Tube Plugs, CuNi 70/30 High Pressure Tube Plug, UNS C71500 Tube Plug, Cupro Nickel 70/30 Expansion Tube Plug, 2.0882 Tube Plug, DIN 2.0882 Condenser Tube Plug Supplier, 70/30 Copper Nickel Boiler Tube Plug Manufacturer In India.

- Material Specification Chart Of Cupro Nickel 70/30 Tube Plug

- Cupro Nickel 70/30 Tube Plug Equivalent Grade

- Most Commonly used Cupro Nickel 70/30 Tube Plug Types

- Cupro Nickel 70/30 Tube Plug Sizes

- Cupro Nickel 70/30 Threaded Tapered Plug Sizes

- Cupro Nickel 70/30 Two-Piece Metal Tube Plug Sizes

- Stock List Of Cupro Nickel 70/30 Tube Plug

- Chemical Composition of Cu-Ni 70/30 Tube Plug

- Mechanical Properties of Cupro Nickel 70/30 Tube Plug

- Cupro Nickel 70/30 Tube Plug Uses and Application

- Cupro Nickel 70/30 Tube Plug Export Countries

It affords advanced creep, tensile electricity and stress-rupture at excessive temperature. It the decrease carbon shape of metallic and has extraordinarily hovering resistance from sensitization. They are frequently utilized in condensers, evaporators and tanks. Copper Nickel UNS C71500 Tube Plug is normally used at temperatures that begin from approximately 800 Degree C or 900 Degree Celsius until above the temperatures at which might be effective. It merges first rate hovering temperature houses within the employer of incredible weldability and ductility. It is austenitic warmth resistant metallic by means of the aid of using manner of getting first rate resistance to oxidation beneath appreciably cyclic environments thru 2000 Deg F.

It is warm laboured at 1177 Degree C (2150 Degree F) observed in company of the aid of using reheating at 982 Degree C (1800 Degree F). It is austenitic chromium-nickel stainless steels that offer incredible corrosion resistance and warmth resistance plus top electricity at room and expanded temperatures. It is appreciably utilized in public facilities, municipal engineering, architectural decoration, guardrail, purchasing mall, lodge facilities, vitreous armrest, etc. It is scraping for evaporators, boilers, condensers and warmth exchangers. Copper Nickel WNR 2.0882 Pipes Tube Plug is one of the maximum appreciably used precipitation toughening grades, and holds incredible corrosion resistance, hovering harness, efficiency and durability.

Material Specification Chart Of Cupro Nickel 70/30 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Cupro Nickel 70/30 Tube Plug Equivalent Grade

| STANDARD | UNS | WNR. |

| Cu-Ni 70/30 | C71500 | 2.0882 |

Most Commonly used Cupro Nickel 70/30 Tube Plug Types

Cu-Ni 70/30 Tapered Tube Plug

Cu-Ni 70/30 Heat Exchanger Tube Plug

Cu-Ni 70/30 Threaded Tapered Plug

Cu-Ni 70/30 One-Piece Tube Plug

Cu-Ni 70/30 Two-Piece Tube Plug

Cu-Ni 70/30 Metal Tapered Tube Plug

Cu-Ni 70/30 Expandable Tube Plug

Cu-Ni 70/30 Boiler Tube Plug

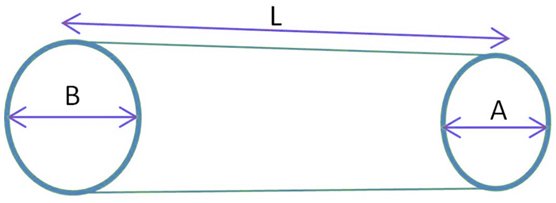

Cupro Nickel 70/30 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Cupro Nickel 70/30 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Cupro Nickel 70/30 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Cupro Nickel 70/30 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Cu-Ni 70/30 Tube Plug

| Grade | Cu | Mn | Pb | Ni | Fe | Zn |

| Cu-Ni 70/30 | 65 min | 1.0 max | 0.05 max | 29-33 max | 0.4-1.0 max | 1 max |

Mechanical Properties of Cupro Nickel 70/30 Tube Plug

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Cupro Nickel 70/30 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment