Hastelloy C22 / C276 Tube Plug

Hastelloy C22 Tube Plug, Hastelloy C-22 Tapered Tube Plug, C276 Hastelloy Two-Piece Tube Plug Manufacturer India, Suppliers of Hastelloy Alloy C276 Heat Exchanger Tube Plug, Alloy C22 Header Plug, Hastelloy C276 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular seller of Hastelloy Alloy C22 / C276 Tube Plug, which are incredibly destroy resistant and correct in dimensions.

It is frequently utilized in Equipment Handling Organic and Fatty Acids, Chemical Storage and Tankers, etc. It is resistance to chloride pitting and crevice corrosion, and resists sulphide pressure corrosion and chloride environments. Hastelloy Alloy UNS N06022 Tube Plug is likewise utilized in oil and fueloline exploration and processing equipment – piping, tubing, and warmth exchangers. It has immune to intergranular corrosion within the as-welded condition.

They are extraordinarily corrosion resistant and paintings hardenable alloys, and additionally has excessive resistance to chloride pressure corrosion cracking. Its layout permits combining advanced resistance to pitting, excessive strength, pressure corrosion, crevice corrosion and cracking. Hastelloy Alloy WNR 2.4602 Tube Plug is likewise utilized in Chemical processing, delivery and storage – strain vessels, tanks, piping, and warmth exchangers. They have excessive ductility and toughness, and still have great resistance to erosion and corrosion in seawater.

Hastelloy® Alloy C-22 High Pressure Tube Plug, Alloy C276 One-Piece Tube Plug Stockist, Nickel Alloy C22 Expansion Tube Plug, 2.4602 Tube Plug, UNS N10276 Metal Tapered Tube Plugs, DIN 2.4819 Condenser Tube Plug Supplier, UNS N06022 Tube Plug, Hastelloy C-276 Boiler Tube Plug Manufacturer In India.

- Material Specification Chart Of Hastelloy C22 / C276 Tube Plug

- Hastelloy C22 / C276 Tube Plug Equivalent Grade

- Most Commonly used Hastelloy C22 / C276 Tube Plug Types

- Hastelloy C22 / C276 Tube Plug Sizes

- Hastelloy C22 / C276 Threaded Tapered Plug Sizes

- Hastelloy C22 / C276 Two-Piece Metal Tube Plug Sizes

- Stock List Of Hastelloy C22 / C276 Tube Plug

- Chemical Composition of Alloy C22 / C276 Tube Plug

- Mechanical Properties of Hastelloy C22 / C276 Tube Plug

- Hastelloy C22 / C276 Tube Plug Uses and Application

- Hastelloy C22 / C276 Tube Plug Export Countries

They have great corrosion and pitting resistance in marine environments, and so are broadly utilized in marine service, tidewater electricity plants, and more. It is advanced for packages related to sulphuric acid, and so has great widespread corrosion resistance to sulfuric acid. Hastelloy Alloy UNS N10276 Tube Plug specifically excels in resisting corrosion to warm sulfuric acids whilst as compared to standard steels. It has best efficiency to weight ratio of any corrosion resistant product. Additions of Copper and Molybdenum content material offer resistance to adversarial environments, pitting, and crevice corrosion.

By means of the additions of niobium, its miles stabilized in opposition to sensitization and resultant intergranular corrosion. Hastelloy Alloy WNR 2.4819 Tube Plug are lengthily used for warmth transmission in improvement equipment which include awesome heaters, boilers condensers and warmth exchangers. It is normally used for a group of capabilities within the marine, electricity generation, offshore and aerospace industries. In seawater, its miles absolutely immune to corrosion at temp approximately six hundred Deg F, deciphering it best for a variety of marine packages.

Material Specification Chart Of Hastelloy C22 / C276 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Hastelloy C22 / C276 Tube Plug Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | OR | GOST |

| Hastelloy C22 | N06022 | 2.4602 | – | NiCr21Mo14W | NW 6022 | – | – |

| Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |

Most Commonly used Hastelloy C22 / C276 Tube Plug Types

Hastelloy C22 / C276 Tapered Tube Plug

Hastelloy C22 / C276 Heat Exchanger Tube Plug

Hastelloy C22 / C276 Threaded Tapered Plug

Hastelloy C22 / C276 One-Piece Tube Plug

Hastelloy C22 / C276 Two-Piece Tube Plug

Hastelloy C22 / C276 Metal Tapered Tube Plug

Hastelloy C22 / C276 Expandable Tube Plug

Hastelloy C22 / C276 Boiler Tube Plug

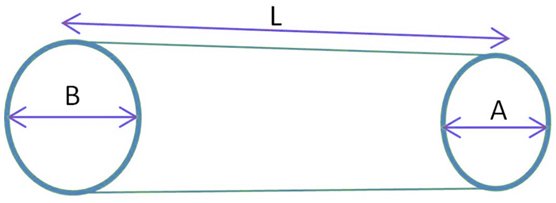

Hastelloy C22 / C276 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Hastelloy C22 / C276 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Hastelloy C22 / C276 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Hastelloy C22 / C276 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy C22 / C276 Tube Plug

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr | W | V |

| Hastelloy C22 | Balance | 0.010 max | 12.5-14.5 | 0.50 max | 0.08 max | 2-6 | 0.02 max | 0.02 max | 2.5 max | 20-22.5 | 2.5-3.5 | 0.35 max |

| Hastelloy C276 | Balance | 0.01 max | 15–17 | 1.0 max | 0.08 max | 4–7 | 0.04 max | 0.03 max | 2.5 max | 14.5–16.5 | 3–4.5 | 0.35 max |

Mechanical Properties of Hastelloy C22 / C276 Tube Plug

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000, MPa – 690 | Psi – 45000, MPa – 310 | 45 % |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |

Hastelloy C22 / C276 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment