Inconel 625 Needle Valve

Inconel Alloy 625 Integral Bonnet Needle Valve, Suppliers of Alloy 625 Hydraulic Needle Valve, 625 Inconel High Pressure Needle Valve Manufacturer, Inconel 625 Compression Needle Valve, Inconel 625 Needle Valve At Factory Price In India.

Vintex Steel & Engg. Co. is a customary supplier of Inconel 625 Needle Valves, which has high-quality corrosion resistance in a wide-ranging series of corrosive media. Inconel alloy 625 needle valve is used in the oil & gas industry, which has a high resistance to corrosion, oxidation, and cracking. Meanwhile, Inconel UNS N06625 Needle Valves has terrific energy at temperatures to 816 Deg C after suitable warmth action. It is utilized in business warmers and for trays, furniture and warmth-treating baskets. It is usually used within the warmth carrying out enterprise for masses of the same programs. These are normally a solitary shutoff needle valve that separates the gauge from the practices. Owning with the great features such as robust design, high-end finish and superior durability these alloy of needles and gauges become the highly demanding product in the market.

Inconel 625 Instrumentation Needle Valve, Alloy 625 Miniature Needle Valve, 2.4856 Needle Valve, Inconel® Alloy 625 Panel Mount Needle Valve, Nickel Alloy 625 Union Bonnet Needle Valve, 625 Inconel Miniature Needle Valve Stockist, DIN 2.4856 Hex Needle Valve Supplier, 1/2 Inch Inconel 625 Needle Valve, UNS N06625 Needle Valve, UNS N06625 Forged Needle Valve Manufacturer In India.

- Material Specification Chart Of Inconel 625 Needle Valve

- Inconel 625 Needle Valve Equivalent Grade

- Most Commonly used Inconel 625 Needle Valve Types

- Dimension Chart Of Alloy 625 Needle Valve

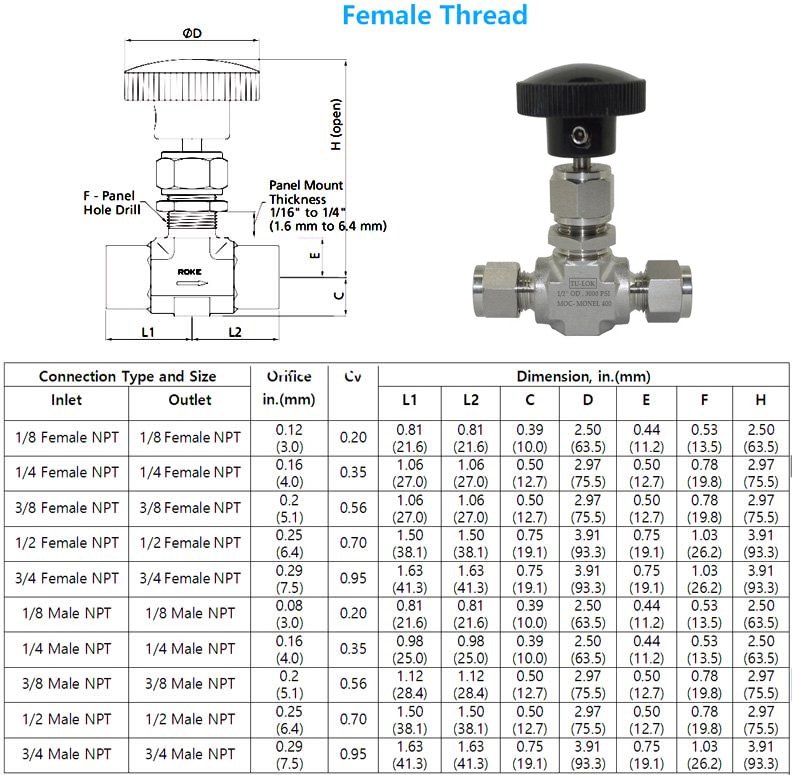

- Alloy 625 Female Thread Needle Valve Dimensions Chart

- Stock List Of Inconel 625 Needle Valve

- Chemical Composition of Inconel Alloy 625 Needle Valve

- Mechanical Properties of Inconel 625 Needle Valve

- Inconel 625 Needle Valve Uses and Application

- Inconel 625 Needle Valve Export Countries

Inconel 625 High Pressure Needle Valve can also be offered in made to order length sizes and shapes, and is also available at market leading prices. Our Inconel 625 Angle Needle Valve provides excellent resistance to oxidation and corrosion and possesses good creep strength. Inconel Alloy WNR 2.4856 Needle Valves are usually utilized in pollutants control, chemical processing parts, nuclear gasoline processing, oil and fuelling recovery, and pickling tank components. Nickel-Alloy 625 Needle Valves is a nickel-chromium alloy this is extraordinarily immune to oxidation during 2200 Deg F. It is an oxidation and corrosion resistant, nonmagnetic, nickel-primarily based totally alloy. It is virtually a Cr-Ni-Fe alloy that deters excessive temp oxidation wherein it indicates high-quality tensile and effect efficiency. It has high-quality resistance to each oxidizing and decreasing acids along with phosphoric and sulphuric.

Material Specification Chart Of Inconel 625 Needle Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Inconel 625 Needle Valve Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | ЭИ602 |

Most Commonly used Inconel 625 Needle Valve Types

Inconel 625 Screwed End Needle Valve

Inconel 625 Tube End Needle Valve

Inconel 625 Socket Weld Needle Valve

Inconel 625 Angle Needle Valve

Inconel 625 Hexagonal Needle Valve

Inconel 625 3 Way Needle Valve

Inconel 625 Union Bonnet Needle Valve

Inconel 625 Panel Mounted Needle Valve

Inconel 625 Forged Needle Valve

Inconel 625 Miniature Needle Valve

Inconel 625 High Pressure Needle Valve

Inconel 625 Bar Stock Needle Valve

Dimension Chart Of Alloy 625 Needle Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Alloy 625 Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of Inconel 625 Needle Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Inconel 625 Needle Valve

- Nickel Alloy 625 Hydraulic Needle Valve Supplier

- 625 Inconel Compression Needle Valve

- UNS N06625 Socket Weld End Needle Valve

- DIN 2.4856 Threaded Needle Valve

- Alloy 625 Integral Bonnet Needle Valve Stockist

- Alloy 625 Screwed End Needle Valve Exporter

- 625 Inconel Flanged Needle Valve

- Inconel Alloy 625 Angle Needle Valve

- Inconel 625 Needle Valve

- Inconel 625 1/2 Inch Needle Valve

- Inconel 625 1rs4 Needle Valve

- Alloy 625 Female Thread Needle Valve

- Inconel JIS NCF 625 3 Way Needle Valve

- Inconel® Alloy 625 Needle Valve

- Inconel 625 High Pressure Needle Valve

- Inconel 625 Flow Control Needle Valves

- 625 Inconel 1/4 Needle Valve

- Inconel 625 Panel Mount Needle Valve

- UNS N06625 Female Male Needle Valves

- UNS N06625 Needle Valve

- Alloy 625 Miniature Needle Valve

- Nickel Alloy 625 Forged Needle Valve Distributor

- Inconel® Alloy 625 Round Body Needle Valve

- Alloy 625 Union Bonnet Needle Valve

- 625 Inconel Hex Needle Valves

- Alloy 625 Single Port Gauge Needle Valve Dealer

- Inconel 625 Industrial Needle Valve Price

- 625 Inconel Straight Needle Valve

- DIN 2.4856 Bar Stock Needle Valve

- Inconel 625 Multi Port Gauge Needle Valve

- Alloy 625 Instrumentation Needle Valve

- 625 Inconel Screwed Bonnet Valve

- Inconel® Alloy 625 Male Needle Valve Manufacturer

- 625 Inconel 90 Deg Angled Needle Valve

Chemical Composition of Inconel Alloy 625 Needle Valve

| Grade | C | Mn | Si | S | Al | Ti | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 0.40 max | 0.40 max | 5.0 max | 58.0 min | 20.0 – 23.0 |

Mechanical Properties of Inconel 625 Needle Valve

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Inconel 625 Needle Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment