Inconel 625 Tube Plug

Alloy 625 Header Plug, 625 Inconel Two-Piece Tube Plug Manufacturer India, Suppliers of Inconel Alloy 625 Heat Exchanger Tube Plug, Inconel 625 Tube Plug, Inconel 625 Tapered Tube Plug, Inconel 625 Tube Plug At Factory Price In India.

Vintex Steel Engg is Manufacturer, Supplier & Exporter of Inconel 625 Tube Plugs & Alloy 625 Tube Plugs in India. Inconel 625 Tube Plug, which is relatively proof against corrosion. These residences and its chemical composition make our valves fabricatable and extraordinarily proof against corrosive environments. we manufacture wide range of Inconel 625 Tube plugs, Alloy 625 High Pressure Tube Plug, UNS N06625 Tube Plug, Inconel 625 Boiler Tube Plug etc. as per International standard like ASME/ASTM/API.

Nickel Alloy 625 Expansion Tube Plug, DIN 2.4856 Condenser Tube Plug Supplier, Alloy 625 One-Piece Tube Plug Stockist, Inconel® Alloy 625 High Pressure Tube Plug, UNS N06625 Tube Plug, Inconel 625 Boiler Tube Plug, UNS N06625 Metal Tapered Tube Plugs, 2.4856 Tube Plug Manufacturer In India.

- Material Specification Chart Of Inconel 625 Tube Plug

- Inconel 625 Tube Plug Equivalent Grade

- Most Commonly used Inconel 625 Tube Plug Types

- Inconel 625 Tube Plug Sizes

- Inconel 625 Threaded Tapered Plug Sizes

- Inconel 625 Two-Piece Metal Tube Plug Sizes

- Stock List Of Inconel 625 Tube Plug

- Chemical Composition of Alloy 625 Tube Plug

- Mechanical Properties of Inconel 625 Tube Plug

- Inconel 625 Tube Plug Uses and Application

- Inconel 625 Tube Plug Export Countries

Inconel Alloy UNS N06625 Tube Plug are fabricated the usage of the advanced grade and are acknowledged for high quality, electricity and resistance to corrosion. They are substantially utilized in various industries which include Chemicals, Fats, & Fertilizers, Sugar Mills & Distilleries, Cement Industries, Ship Builders, Paper Industries etc. Inconel Alloy UNS N06625 Tube Plug is nickel-copper primarily based totally alloy comprised basically of two-thirds nickel and one-thirds copper. It is used for resistance to plenty of corrosive conditions, consisting of alkalis (or acid like substances), saltwater, hydrofluoric acid and sulphuric acid. Meanwhile, these Inconel 625 Tube Plugs are offered in different sizes and shapes to our customers. We offer inconel 625 Tube Plug in different sizes, specifications and shapes as per demands of our esteemed customers.

Material Specification Chart Of Inconel 625 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Inconel 625 Tube Plug Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | EN | JIS | BS | GOST | OR |

| Inconel 625 | N06625 | 2.4856 | NC22DNB4M | NiCr22Mo9Nb | NCF 625 | NA 21 | ХН75МБТЮ | ЭИ602 |

Most Commonly used Inconel 625 Tube Plug Types

Inconel 625 Tapered Tube Plug

Inconel 625 Heat Exchanger Tube Plug

Inconel 625 Threaded Tapered Plug

Inconel 625 One-Piece Tube Plug

Inconel 625 Two-Piece Tube Plug

Inconel 625 Metal Tapered Tube Plug

Inconel 625 Expandable Tube Plug

Inconel 625 Boiler Tube Plug

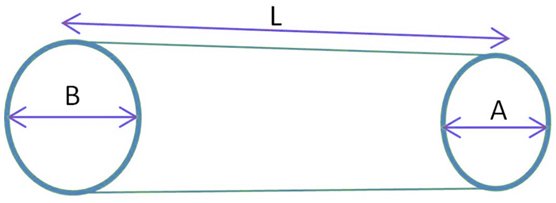

Inconel 625 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Inconel 625 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Inconel 625 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Inconel 625 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy 625 Tube Plug

| Grade | C | Mn | Si | S | Al | Ti | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | 0.40 max | 0.40 max | 5.0 max | 58.0 min | 20.0 – 23.0 |

Mechanical Properties of Inconel 625 Tube Plug

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa -930 | Psi – 75,000 , MPa – 517 | 42.5 % |

Inconel 625 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment