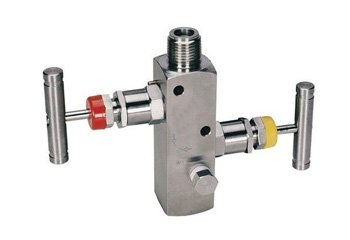

Monel 400 / K500 Manifold Valves

Monel 400 2 Way Manifold Valves, Monel Alloy 400 Manifold Tuning Valve, K500 Monel 5 Way Manifold Valve Manufacturer India, Alloy 400 Manifold Valves , Suppliers of Alloy 400 3 Way Manifold Valve, Monel K500 Manifold Heat Control Valve At Factory Price In India.

Vintex Steel & Engg. Co. is supplier of Monel 400 / K500 Manifold Valves, which shows off higher corrosion resistance.

We are the leading manufacturer, exporter and reliable supplier of top notch quality of Manifold valves. With a team of highly trained specialist, the manufacturing process is conducted in high modern machines and inventories which ultimately increase the efficiency and quality of the valves. It is likewise fine for excessive temperature provider due to its appropriate mechanical properties. It is a change with a better carbon content, to offer progressed excessive temperature electricity. Monel UNS N04400 Manifold Valves is titanium stabilized austenitic metallic with appropriate standard corrosion resistance.

Monel® Alloy 400 Manifold Heat Control Valve Stockist, UNS N05500 Manifold Valve, Monel 400 R-Type 2 Way Manifold Valve, Nickel Alloy 400 Hydraulic Manifold Valve, Monel K500 H-Type 3 way Manifold, DIN 2.4375 Direct-Mount Manifolds, UNS N04400 Manifold Solenoid Valve, 2.4360 Manifold Valve Supplier, Alloy K500 V / VB and VL series Manifolds Manufacturer In India.

- Material Specification Chart Of Monel 400 / K500 Manifold Valves

- Monel 400 / K500 Manifold Valves Equivalent Grade

- Most Commonly used Monel 400 / K500 Manifold Valves Types

- Dimensions Of Monel Alloy 400 / K500 Two Way Manifold Valve

- Stock List Of Monel 400 / K500 Manifold Valves

- Chemical Composition of Monel Alloy 400 / K500 Manifold Valves

- Mechanical Properties of Alloy 400 / K500 Manifold Valves

- Monel 400 / K500 Manifold Valves Uses and Application

- Monel 400 / K500 Manifold Valves Export Countries

It is the grade of choice for programs within the temperature variety of as much as about 900°C, merging excessive electricity, resistance to scaling and section balance within the organization of resistance to following aqueous corrosion. Our entire production process is performed under the supervision of qualified professionals that adhered to obtain the national and international standard product. We supply our product in customized shape, length, size, grade and dimensions as per the requisites and order mention by the clients. They are substantially extra resistant than any of the opposite chromium-nickel kinds to answers of sulphuric acid. Monel UNS N05500 Manifold Valves are molybdenum-bearing austenitic steels which might be extra immune to standard corrosion and pitting/crevice corrosion than the traditional chromium-nickel austenitic steels. In addition to incredible corrosion resistance and electricity properties, it additionally affords incredible fabric ability and formability which might be traditional of the austenitic steels. Monel WNR 2.4375 Manifold Valves additionally gives better creep, stress-rupture and tensile electricity at increased temperature. They have incredible weld-ability, without or with the addition of filler metal.

Material Specification Chart Of Monel 400 / K500 Manifold Valves

| Size | 1/8″ To 1″ |

| Working Pressures | up to 6000 psig (413 bar) |

| Temperatures | up to 1200°F (648°C) with Grafoil valve packing |

| Thread | NPT, BSPP, BSPT |

| Connection | Threaded, Flange End |

| Type | R Type, T Type, H Type |

| Function | 2 Way, 3 Way, 5 Way |

| Body Shape | Square, Rectangle |

| Pressure Rating | 1500 Psi, 3000 Psi, 6000 Psi, 10000 Psi, 15,000 Psi |

| Orifice Size | 2 Mm To 9.5 Mm |

| Media Temperature | (-120* C To 500*C ) Range As Per Pressure |

| Body Type | Bar Stock, Forged |

| Handle | Bar T-Handle |

| Packing Details | Box Packing, Wooden Pallet |

| Equivalent Brands | Swagelok, Parker, Rose Mount, Hamlet, Oliver Valves, Hoke |

Monel 400 / K500 Manifold Valves Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

| Monel K500 | 2.4375 | N05500 | – | – | – | – | – |

Most Commonly used Monel 400 / K500 Manifold Valves Types

Manifold - R Type - 2 Way-01

Manifold - R Type - 2 Way-02

Manifold - R Type - 2 Way-03

Manifold - R Type - 2 Way-04

Manifold - R Type - 2 Way-05

Manifold - R Type - 2 Way-06 (Direct Mounting)

Manifold - T Type - 2 Way (Direct Mounting)

Manifold - R - 3 Way-01

Manifold - R - 3 Way-02 (Direct Mounting)

Manifold - T - 3 Way-02 (Direct Mounting)

Manifold - H - 3 Way-02 (Direct Mounting)

Manifold - R - 5 Way -01

Manifold - R - 5 Way - 02 (Direct Mounting)

Manifold - R - 5 Way - 03 (Direct Mounting)

Manifold - T - 5 Way (Direct Mounting)

Manifold - H - 5 Way (Direct Mounting)

Dimensions Of Monel Alloy 400 / K500 Two Way Manifold Valve

| END CONNECTIONS | DIMENSION | ||

| Process Connection | Instrument Connection | A | B |

| 1/4″ FEMALE | 1/4″ MALE | 24 | 80 |

| 1/4″ FEMALE | 1/4″ FEMALE | 24 | 80 |

| 1/4″ MALE | 1/4″ MALE | 24 | 80 |

| 1/2″FEMALE | 1/2″ MALE | 30 | 115 |

| 1/2″ MALE | 1/2″FEMALE | 30 | 115 |

| 1/2″ MALE | 1/2″ MALE | 30 | 115 |

| 3/4″ FEMALE | 1/2″ MALE | 30 | 115 |

| 1/2″ MALE | 3/4″ FEMALE | 38 | 115 |

| 3/4″ FEMALE | 3/4″ MALE | 38 | 115 |

| 3/4″ FEMALE | 3/4″ FEMALE | 38 | 115 |

| 3/4″ MALE | 3/4″ MALE | 38 | 115 |

Other Related Products

Test Certificates Of Monel Alloy 400 / K500 Manifold Valves

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Monel 400 / K500 Manifold Valves

- Monel K500 T-Type 5 Way Valve

- Monel Alloy 400 5 Way Manifold Valve

- Monel® Alloy 400 R – Type Manifold Valve

- Monel K500 R Type 5 Way Manifold Valve Exporter

- Alloy 400 Hydraulic Manifold Valve Stockist

- Monel® Alloy 400 Manifold Valves

- K500 Monel 3 Way T- Type Manifold Valves

- Nickel Alloy 400 H-Type 3 Way Manifold Valve

- Monel JIS NW 4400 3 Valve Manifold

- K500 Monel Instrument Manifolds

- Monel 400 Manifold Valves

- Monel 400 2 Way Manifold Valve

- Monel 400 3 Way Manifold Valves

- Alloy 400 H Series Manifold Valves Supplier

- Monel 400 Manifold Valves at Best Price in India

- DIN 2.4360 Manifold Heat Control Valve

- UNS N04400 Manifold Tuning Valve

- 400 Monel Alloy H-Type 5 Way Manifold Valve

- Monel K500 5 Way Pipe to Pipe Manifold Valves

- Monel 400 MANIFOLD-R-2 Way-06 Dealer

- 400 Monel 5 Way T Type Manifold Valve

- 400 Monel 5 Way R Type Manifold Valve

- Monel® Alloy 400 Three Way Manifold (T Type)

- UNS N04400 Fuel Manifold Valve

- Alloy 400 H-Type 2 Way Manifold Valves Distributor

- 400 Monel Manifold Heat Control Valve

- Monel 400 Industrial Manifold Valves Price

- Alloy 400 3 Way R Type Manifold Valve Manufacturer

- Alloy K500 2 Way R Type Manifold Valve

- UNS N05500 R-2 Way-03 Manifold Valves

- Alloy 400 5 Way Manifold Valves, T Type, Direct Mounting

- Monel® Alloy 400 “R” Type 5 Way Manifold Valves

- Monel K500 2 Valve Manifold-H Type

- DIN 2.4375 3 Way R Type Manifold Valve

Chemical Composition of Monel Alloy 400 / K500 Manifold Valves

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

| Monel K500 | 0.25 max | 1.5 max | 0.5 max | 0.010 max | 27.00 – 33.00 | 0.5 – 2 | 63.00 min |

Mechanical Properties of Alloy 400 / K500 Manifold Valves

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

| Monel K500 | 8.44 g/cm3 | 1350 °C (2460 °F) | Psi – 160000 , MPa – 1100 | Psi – 115000 , MPa – 790 | 20 % |

Monel 400 / K500 Manifold Valves Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment