Monel 400 Needle Valve

Monel Alloy 400 Integral Bonnet Needle Valve, 400 Monel High Pressure Needle Valve Manufacturer, Suppliers of Alloy 400 Hydraulic Needle Valve, Monel 400 Compression Needle Valve, Monel 400 Needle Valve At Factory Price In India.

Vintex Steel & Engg. Co. is an accustomed manufacturer, exporter and supplier of Monel 400 Needle Valves, which has incredible resistance to corrosion, crevice corrosion, and pitting. The valves are made of high-quality material or forging process and are made available to customers in different sizes, end connections, sealing styles and stem types as well as in angle and straight patterns. It is well-thought-out as not going due to its durable texture, power and top notch corrosion resistance. The corrosion resistance of such valves additionally unearths different makes use of within the chemical, meals, pharmaceutical, electricity generation, and plastics industries. It reveals top notch corrosion resistance in chemical environments containing phosphoric acid, nitric acid, chlorides and sulphuric acid.

Alloy 400 Miniature Needle Valve, 1/2 Inch Monel 400 Needle Valve, Monel 400 Instrumentation Needle Valve, 400 Monel Miniature Needle Valve Stockist, DIN 2.4360 Hex Needle Valve Supplier, 2.4360 Needle Valve, UNS N04400 Needle Valve, UNS N04400 Forged Needle Valve, Monel® Alloy 400 Panel Mount Needle Valve, Nickel Alloy 400 Union Bonnet Needle Valve Manufacturer In India.

- Material Specification Chart Of Monel 400 Needle Valve

- Monel 400 Needle Valve Equivalent Grade

- Most Commonly used Monel 400 Needle Valve Types

- Dimension Chart Of Alloy 400 Needle Valve

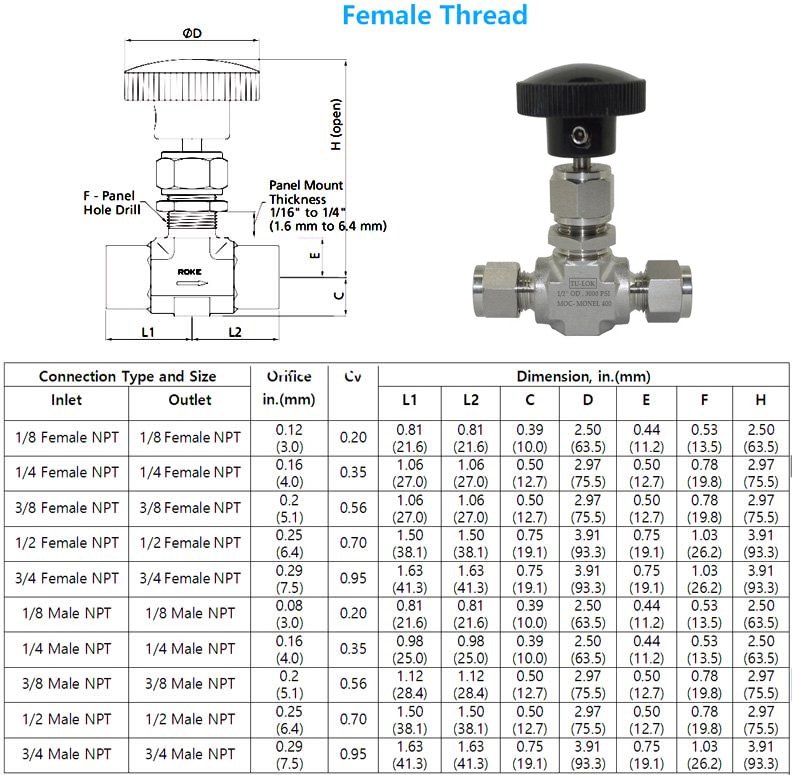

- Alloy 400 Female Thread Needle Valve Dimensions Chart

- Stock List Of Monel 400 Needle Valve

- Chemical Composition of Monel Alloy 400 Needle Valve

- Mechanical Properties of Monel 400 Needle Valve

- Monel 400 Needle Valve Uses and Application

- Monel 400 Needle Valve Export Countries

Monel 400 Needle Valves is well known for its high strength and corrosion resistant properties. It works in a wide range of temperatures, and is available in multiple forms for a variety of products. It is a columbium stabilized cloth that mixes incredible corrosion resistance with increased mechanical houses and comparatively smoothest fabrication. It is a nickel-iron-chromium austenitic alloy that becomes evolved for max resistance to acid attack, exactly sulphuric acid. It is stabilized with columbium to reduce carbide precipitation all through welding. It especially excels in resisting corrosion to warm sulphuric acids whilst as in comparison to standard stainless.

It has numerous noteworthy houses which include – having decreased however greater consistent rate compared to different nickel primarily based totally alloys. It is famous due to its incredible corrosion resistance, potency, and long-time period texture.

Material Specification Chart Of Monel 400 Needle Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

Monel 400 Needle Valve Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Monel 400 | 2.4360 | N04400 | NW 4400 | NA 13 | МНЖМц 28-2,5-1,5 | NU-30M | NiCu30Fe |

Most Commonly used Monel 400 Needle Valve Types

Monel 400 Screwed End Needle Valve

Monel 400 Tube End Needle Valve

Monel 400 Socket Weld Needle Valve

Monel 400 Angle Needle Valve

Monel 400 Hexagonal Needle Valve

Monel 400 3 Way Needle Valve

Monel 400 Union Bonnet Needle Valve

Monel 400 Panel Mounted Needle Valve

Monel 400 Forged Needle Valve

Monel 400 Miniature Needle Valve

Monel 400 High Pressure Needle Valve

Monel 400 Bar Stock Needle Valve

Dimension Chart Of Alloy 400 Needle Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

Alloy 400 Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of Monel 400 Needle Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Monel 400 Needle Valve

- Monel 400 1rs4 Needle Valve

- Monel 400 High Pressure Needle Valve

- UNS N04400 Socket Weld End Needle Valve

- 400 Monel 1/4 Needle Valve

- 400 Monel Flanged Needle Valve

- Monel 400 1/2 Inch Needle Valve

- 400 Monel Compression Needle Valve

- Alloy 400 Integral Bonnet Needle Valve Stockist

- Monel 400 Needle Valve

- Alloy 400 Female Thread Needle Valve

- Monel® Alloy 400 Needle Valve

- DIN 2.4360 Threaded Needle Valve

- Monel 400 Flow Control Needle Valves

- Monel Alloy 400 Angle Needle Valve

- Alloy 400 Screwed End Needle Valve Exporter

- Monel JIS NW 4400 3 Way Needle Valve

- Nickel Alloy 400 Hydraulic Needle Valve Supplier

- Monel® Alloy 400 Round Body Needle Valve

- 400 Monel Hex Needle Valves

- UNS N04400 Needle Valve

- Monel 400 Multi Port Gauge Needle Valve

- Alloy 400 Miniature Needle Valve

- Monel 400 Union Bonnet Needle Valve

- Nickel Alloy 400 Forged Needle Valve Distributor

- Alloy 400 Single Port Gauge Needle Valve Dealer

- 400 Monel Screwed Bonnet Valve

- Monel® Alloy 400 Male Needle Valve Manufacturer

- DIN 2.4360 Bar Stock Needle Valve

- 400 Monel 90 Deg Angled Needle Valve

- Monel 400 Panel Mount Needle Valve

- Alloy 400 Instrumentation Needle Valve

- Monel 400 Industrial Needle Valve Price

- UNS N04400 Female Male Needle Valves

- 400 Monel Straight Needle Valve

Chemical Composition of Monel Alloy 400 Needle Valve

| Grade | C | Mn | Si | S | Cu | Fe | Ni |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

Mechanical Properties of Monel 400 Needle Valve

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Monel 400 Needle Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment