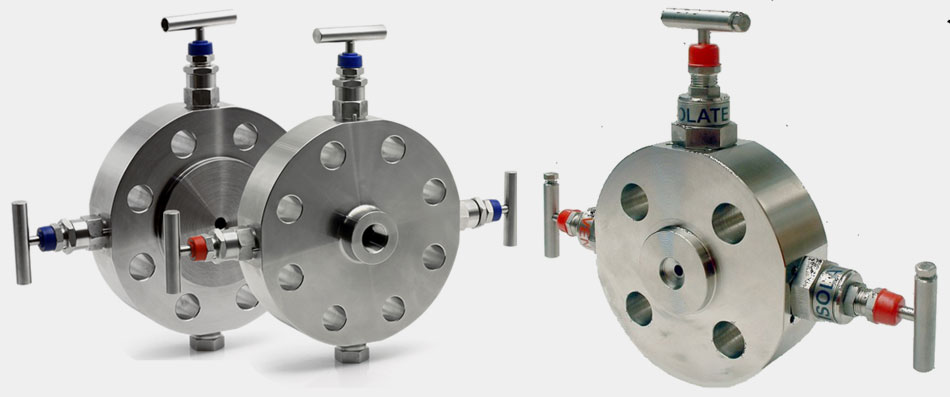

MonoFlange Valves

Monoflange Single Block Valve, Monoflange Valve Double Block Bleed, Monoflange Manifolds, Suppliers of Monoflange Valves, Single Block Monoflange Valves At Factory Price In India.

Vintex Steel & Engg. Co. is an acquainted manufacturer and exporter of MonoFlange Valves, which does now no longer reply or harden from warmness treatments.

It is likewise tougher than stainless by way of a protracted stringy chip, in which the usage of chip breakers is recommended. It has more power beneath welding; its merchandise are stronger. It changed into advanced in most cases to withstand extra correctly the assault of sulphurous acid compounds. Shearing, stamping, heading and drawing may be effectively accomplished in such valves. Stainless Steel MonoFlange Valves is normally determined within the fabric industry, in which its power and corrosion resistance may be utilized. To remove internal stresses, a post-paintings annealing is recommended in those vales, that is immune to corrosion from such substances.

Bleed Monoflange Valve, Key Block DBB Valves, Stainless Steel Monoflange Valves, Alloy Steel Monoflange Instrument Valves, Carbon Steel Bleed Monoflange Valves, CS Single Block Monoflange Valve Supplier, Monoflange DBB Valve Stockist, Monoflange Ball Valves Manufacturer In India.

- Material Specification Chart Of MonoFlange Valves

- Most Commonly used MonoFlange Valves Types

- Monoflange Single Block & Bleed Valve Dimensions

- Double Block & Bleed Monoflange Dimensions

- Process Monoflanges Valve Weight

- Instrument Monoflange Weight

- Stock List Of MonoFlange Valves

- MonoFlange Valves Uses and Application

- MonoFlange Valves Export Countries

It has advanced creep, stress-to-rupture and tensile powers than different steels. By itself, it’s far not unusual place to find valves in equipment utilized in pulp and paper mills. In addition to molybdenum, it additionally incorporates some of different factors in various concentrations. The most temperature of such Carbon Steel MonoFlange Valves for scaling resistance in non-stop offerings is set 1650 Deg F, and 1500 Deg F for intermittent service. High temperature resistance is likewise compounded via way of its titanium content material, which lets in to be proof against precipitation at those temperatures. It is the desired metallic to be used in marine environments due to its more resistance to pitting corrosion than different grades of metallic.

It is suggested whilst publicity within side the carbide precipitation variety is unavoidable and in which annealing after welding isn’t practical. It incorporates an addition of molybdenum in its composition. Super Duplex Steel MonoFlange Valves is molybdenum-alloyed metallic and is the second one maximum not unusual place austenite metallic. It has advanced corrosion resistance in tough environments. Not unexpectedly, trendy corrosion resistance and different homes of those vales intently correspond to the ones this is titanium stabilised model of molybdenum-bearing austenitic chrome steel type. It is appropriate for welding as it has carbon content material decrease than collection alloys to keep away from carbide precipitation in welding applications.

Material Specification Chart Of MonoFlange Valves

| Flange Size | 1/2″ NB TO 2″ NB |

| Construction as Per | ANSI B16.5 |

| Standard Outlet | 1/2″ NPT (F) |

| Standard Vent | 1/4″ NPT (F) |

| Other Connections | Threaded, Tube End, Socket Weld |

| Flange Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Packing & Seat Material | PTFE, GRAPHOIL, PEEK |

| Body Type | Bar Stock, Forged |

| Handle | T Handle |

| Material | SS 316, SS 304, SS 316 Ti, Copper, Brass, Duplex, CS, Inconel, Super Duplex, Hastelloy, Monel, Alloy 20, SMO 254, 904L, Titanium & All Other Alloys |

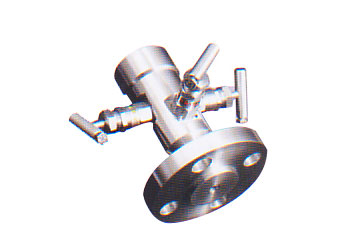

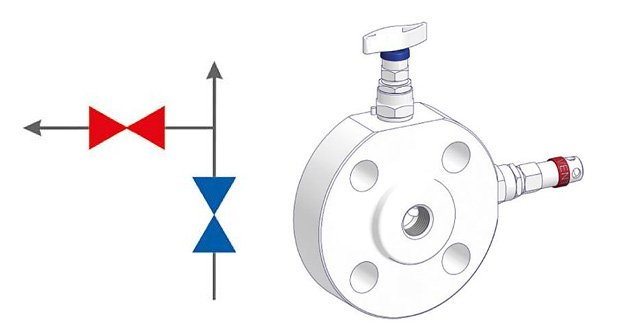

Most Commonly used MonoFlange Valves Types

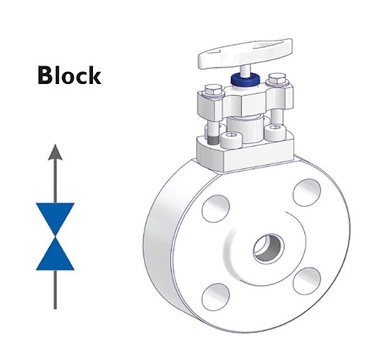

Double Block & Bleed Valve Monoflange

Monoflange Block & Bleed Valve

Monoflange Process Valve

Monoflange Single Isolation Valve

Instrumentation Double Block & Bleed Monoflange

Monoflange DBB Valves

Key Block DBB Valves

Customized Monoflange Valve

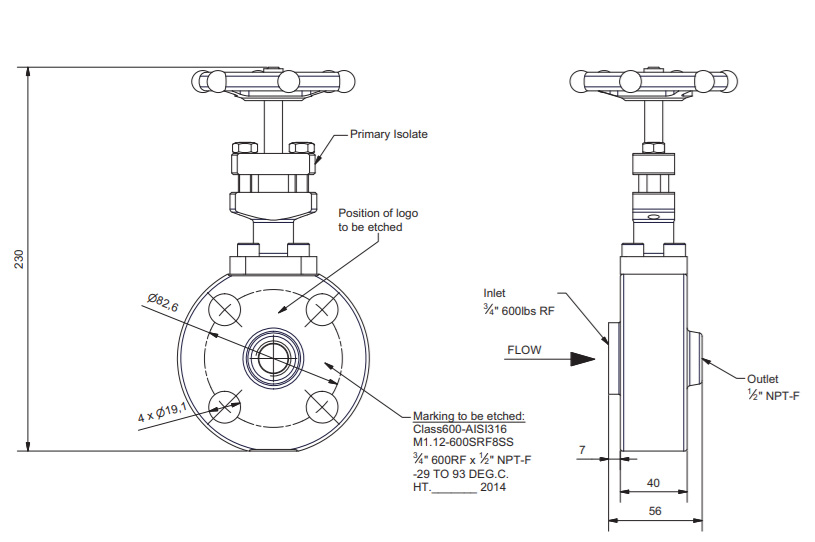

Monoflange Single Block & Bleed Valve Dimensions

| SIZE | RATING | A | ØB | ØC |

| (inch) | (#) | (mm) | (mm) | (mm) |

| ½" | 150 | 57 | 90 | 2 |

| 3/4" | 150 | 57 | 100 | 2 |

| 1" | 150 | 57 | 110 | 2 |

| 11/2" | 150 | 60 | 125 | 2 |

| 2" | 150 | 63 | 150 | 2 |

| 1/2" | 300 | 57 | 95 | 2 |

| 3/4" | 300 | 60 | 115 | 2 |

| 1" | 300 | 60 | 125 | 2 |

| 11/2" | 300 | 63 | 155 | 2 |

| 2" | 300 | 63 | 165 | 2 |

| 1/2" | 600 | 61 | 95 | 7 |

| 3/4" | 600 | 64 | 115 | 7 |

| 1" | 600 | 64 | 125 | 7 |

| 11/2" | 600 | 67 | 155 | 7 |

| 2" | 600 | 67 | 165 | 7 |

| 1/2" | 900 | 64 | 120 | 7 |

| 3/4" | 900 | 64 | 130 | 7 |

| 1" | 900 | 67 | 150 | 7 |

| 11/2" | 900 | 67 | 180 | 7 |

| 2" | 900 | 72 | 215 | 7 |

| 1/2" | 1500 | 60 | 120 | 7 |

| 3/4" | 1500 | 60 | 130 | 7 |

| 1" | 1500 | 60 | 150 | 7 |

| 11/2" | 1500 | 60 | 180 | 7 |

| 2" | 1500 | 72 | 215 | 7 |

| ½" | 2500 | 60 | 135 | 7 |

| 3/4" | 2500 | 60 | 140 | 7 |

| 1" | 2500 | 60 | 160 | 7 |

| 11/2" | 2500 | 72 | 205 | 7 |

| 2" | 2500 | 72 | 235 | 7 |

Double Block & Bleed Monoflange Dimensions

| SIZE | ØC | A | RATING | ØB |

| (inch) | (mm) | (mm) | (#) | (mm) |

| 1/2" | 2 | 57 | 150 | 90 |

| 3/4" | 2 | 57 | 150 | 100 |

| 1" | 2 | 57 | 150 | 110 |

| 11/2" | 2 | 60 | 150 | 125 |

| 2" | 2 | 63 | 150 | 150 |

| 1/2" | 2 | 57 | 300 | 95 |

| 3/4" | 2 | 60 | 300 | 115 |

| 1" | 2 | 60 | 300 | 125 |

| 11/2" | 2 | 63 | 300 | 155 |

| 2" | 2 | 63 | 300 | 165 |

| 1/2" | 7 | 61 | 600 | 95 |

| 3/4" | 7 | 64 | 600 | 115 |

| 1" | 7 | 64 | 600 | 125 |

| 11/2" | 7 | 67 | 600 | 155 |

| 2" | 7 | 67 | 600 | 165 |

| 1/2" | 7 | 64 | 900 | 120 |

| 3/4" | 7 | 64 | 900 | 130 |

| 1" | 7 | 67 | 900 | 150 |

| 11/2" | 7 | 67 | 900 | 180 |

| 2" | 7 | 72 | 900 | 215 |

| 1/2" | 7 | 60 | 1500 | 120 |

| 3/4" | 7 | 60 | 1500 | 130 |

| 1" | 7 | 60 | 1500 | 150 |

| 11/2" | 7 | 60 | 1500 | 180 |

| 2" | 7 | 72 | 1500 | 215 |

| 1/2" | 7 | 60 | 2500 | 135 |

| 3/4" | 7 | 60 | 2500 | 140 |

| 1" | 7 | 60 | 2500 | 160 |

| 11/2" | 7 | 72 | 2500 | 205 |

| 2" | 7 | 72 | 2500 | 235 |

Other Related Products

Process Monoflanges Valve Weight

| Flange Size (in) |

Approx.Weight (kg) |

ØD (mm) | Flange Class | Flange Face | |

| RTJ x mm | RF x mm | ||||

| 1/2 | 2.05 | 98.06 | 150 | – | 36.06 |

| 1/2 | 2.06 | 98.06 | 300 | 40.06 | 36.06 |

| 1/2 | 2.06 | 98.06 | 600 | 40.06 | 41.04 |

| 1/2 | 3.05 | 120.07 | 900 / 1,500 | 41.04 | 41.04 |

| 1/2 | 4.03 | 133.04 | 2,500 | 41.04 | 41.04 |

| 3/4 | 2.06 | 98.06 | 150 | – | 36.06 |

| 3/4 | 3.05 | 117.03 | 300 | 41.04 | 36.06 |

| 3/4 | 3.05 | 117.03 | 600 | 41.04 | 41.04 |

| 3/4 | 4.01 | 130.00 | 900 / 1,500 | 41.04 | 41.04 |

| 3/4 | 4.08 | 139.07 | 2,500 | 41.04 | 41.04 |

| 1 | 3.00 | 108.00 | 150 | 41.04 | 36.06 |

| 1 | 3.09 | 124.00 | 300 | 41.04 | 36.06 |

| 1 | 3.09 | 124.00 | 600 | 41.04 | 41.04 |

| 1 | 5.01 | 149.03 | 900 / 1,500 | 41.04 | 41.04 |

| 1 | 6.01 | 158.08 | 2,500 | 42.04 | 42.04 |

| 1 1/2 | 4.01 | 127.00 | 150 | 41.04 | 36.06 |

| 1 1/2 | 6.00 | 155.04 | 300 | 41.04 | 36.06 |

| 1 1/2 | 6.00 | 155.04 | 600 | 41.04 | 41.04 |

| 1 1/2 | 7.04 | 177.08 | 900 / 1,500 | 41.04 | 41.04 |

| 1 1/2 | 11.04 | 203.02 | 2,500 | 52.09 | 51.04 |

| 2 | 5.04 | 152.04 | 150 | 41.04 | 36.06 |

| 2 | 6.04 | 165.01 | 300 | 42.09 | 36.06 |

| 2 | 6.09 | 165.01 | 600 | 42.09 | 41.04 |

| 2 | 12.00 | 215.09 | 900 / 1,500 | 46.09 | 45.04 |

| 2 | 17.05 | 235.00 | 2,500 | 59.09 | 58.04 |

Instrument Monoflange Weight

| Flange Size (in) |

Approx. Weight (kg) |

ØD (mm) | Flange Class | Flange Face | |

| RTJ x mm | RF x mm | ||||

| 1/2 | 1.06 | 88.09 | 150 | – | 33.06 |

| 1/2 | 2.00 | 95.03 | 300 | 37.06 | 33.06 |

| 1/2 | 2.00 | 95.03 | 600 | 37.06 | 38.04 |

| 1/2 | 2.09 | 120.07 | 900 / 1,500 | 38.04 | 38.04 |

| 1/2 | 3.07 | 133.04 | 2,500 | 38.04 | 38.04 |

| 3/4 | 2.00 | 98.06 | 150 | – | 33.06 |

| 3/4 | 2.09 | 117.03 | 300 | 38.04 | 33.06 |

| 3/4 | 2.09 | 117.03 | 600 | 38.04 | 38.04 |

| 3/4 | 3.05 | 130.00 | 900 / 1,500 | 38.04 | 38.04 |

| 3/4 | 4.02 | 139.07 | 2,500 | 39.04 | 39.04 |

| 1 | 2.06 | 108.00 | 150 | 38.04 | 36.06 |

| 1 | 3.03 | 124.00 | 300 | 38.04 | 36.06 |

| 1 | 3.03 | 124.00 | 600 | 38.04 | 38.04 |

| 1 | 6.08 | 149.03 | 900 / 1,500 | 38.04 | 38.04 |

| 1 | 5.07 | 158.08 | 2,500 | 42.04 | 42.04 |

| 1 1/2 | 3.08 | 127.00 | 150 | 38.04 | 36.06 |

| 1 1/2 | 5.03 | 155.04 | 300 | 38.04 | 36.06 |

| 1 1/2 | 5.03 | 155.04 | 600 | 38.04 | 38.04 |

| 1 1/2 | 6.08 | 177.08 | 900 / 1,500 | 39.04 | 39.04 |

| 1 1/2 | 11.05 | 203.02 | 2,500 | 52.09 | 51.04 |

| 2 | 5.01 | 152.04 | 150 | 38.04 | 36.06 |

| 2 | 5.07 | 165.01 | 300 | 39.09 | 36.06 |

| 2 | 6.02 | 165.01 | 600 | 39.09 | 38.04 |

| 2 | 11.06 | 215.09 | 900 / 1,500 | 46.09 | 45.04 |

| 2 | 17.00 | 235.00 | 2,500 | 59.09 | 58.04 |

Stock List Of MonoFlange Valves

- Monoflange Valves Exporter

- Stainless Steel 304 Monoflange Valves

- SS 316 Monoflange Valves

- Monoflange Double Block And Bleed Valve

- Monoflange Valves Premiere Quality

- Mono Flange Butterfly Valve

- Titanium Monoflange Valves

- Monoflange Needle Valves

- Monel Monoflange Valves

- Incoloy Monoflange Valves

- Monoflange Valves Stockist

- Monoflange Single Block & Bleed Valve

- Copper Nickel Monoflange Valves

- Monoflange DBB Valve

- Hastelloy Monoflange Valves

- Monoflange Gate Valve Dealer

- SS 304L Monoflange Valves Manufacturer

- Slimline Monoflange Valves

- Monoflange Ball Valve

- Diagram Block & Bleed Monoflange Valves

- Alloy 20 Monoflange Valves

- Alloy Steel Monoflange Valves

- Instrument Monoflange Valves

- Monoflange Valves Stockist In Mumbai

- SMO 254 Monoflange Valves

- Monoflange Valves at Best Price in India

- Industrial Monoflange Valves Supplier

- Monoflange Valves Distributor

- Bleed Monoflange Valves

- SS 316L Monoflange Valves

- Monoflange Single Isolation Valve

- CS Monoflange Valves

- Super Duplex Steel Monoflange Valves

- Key Block DBB Valves

- Single Block Monoflange Valves

- Stainless Steel Monoflange Valve

- Nickel Alloy Monoflange Valves

- Parker Monoflange Valve

MonoFlange Valves Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment