Nickel Alloy 200 / 201 Instrumentation Ball Valves

Nickel 200 2 Way Ball Valves Manufacturer, Suppliers of Alloy 200 High Pressure Ball Valve, Nickel Alloy 200 One-Piece Instrumentation Ball Valves, Nickel Alloy 201 3 Piece Ball Valves, Nickel Alloy 201 Instrumentation Ball Valves At Factory Price In India.

Vintex Steel & Engg. Co. is a standard supplier of Nickel Alloy 200 / 201 Instrumentation Ball Valves, which contains decrease carbon content material ensuing in decrease hardness.

Nickel Alloy UNS N02200 Instrumentation Ball Valves is specifically used for increased temperature packages specifically because of the gain in their oxidation resistance.We are fulfilling the industrial project requirements for the decades since we meet all international quality standards and government norms for excellence in the area. The Nickel Alloy Ball Valve is one of the most commonly used. It has a ball inside the body with handle attached to it. Due to its excessive chromium and nickel content material, the overall corrosion resistance of such valves is extra advanced in maximum environments. Nickel Alloy UNS N02201 Instrumentation Ball Valves is extensively utilized by the fabrication enterprise and all trendy welding strategies may be used on pipes.

Nickel Alloy 201 Lined Ball Valves, Nickel Alloy 201 Trunnion Ball Valves, Nickel Alloy 200 2 Piece Ball Valves, Nickel 200 Flanged Ball Valves, DIN 2.4066 4 Way Ball Valve Supplier, UNS N02201 Four Way Ball Valves, UNS N02200 Instrumentation Ball Valve, Alloy 201 Rising Stem Ball Valve Stockist, 2.4068 Multiport Ball Valve, Nickel Alloy 200 Ball Valve Manufacturer In India.

- Material Specification Chart Of Nickel 200 / 201 Ball Valves

- Nickel Alloy 200 / 201 Ball Valves Equivalent Grade

- Most Commonly used Nickel Alloy 200 / 201 Ball Valves Types

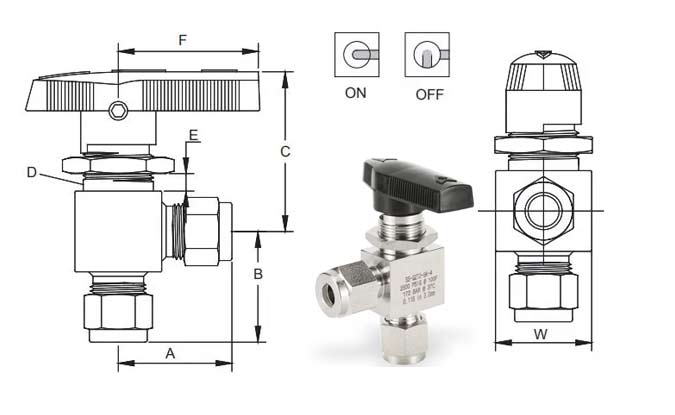

- Dimensions Of Alloy 200 / 201 Instrumentation Ball Valves

- Stock List Of Alloy 200 / 201 Instrumentation Ball Valves

- Chemical Composition of Nickel 200 / 201 Instrumentation Ball Valves

- Mechanical Properties of Nickel Alloy 200 / 201 Ball Valve

- Nickel Alloy 200 / 201 Ball Valves Uses and Application

- Nickel 200 / 201 Instrumentation Ball Valves Export Countries

Moreover, the development of the same product is done by considering the national as well as international product quality standards and according to set manufacturing norms. It is non-magnetic, while Titanium Heat Exchanger Tubes has drastically better melting factor than different metallic alloys. Nickel Alloy WNR 2.4066 Instrumentation Ball Valves are utilized in numerous packages including Heat exchangers and condensers, Automobile exhaust pipe, Marine equipments, and so on. Applications of such valves are Chemical Industry, Pulp and Paper Manufacturing, Heat Exchangers and Process Piping. Applications of such valves also are Chemical Process Equipments, Pharmaceutical, Food Processing, Heat Exchangers, Process Piping, Valves and Pumps.

Material Specification Chart Of Nickel 200 / 201 Ball Valves

| Size | 1/8″ To 2″ / 6 Mm To 50 Mm |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way, 4 Way, 5 Way |

| Pressure Rating | 1500 Psi, 3000 Psi, 6000 Psi, 10000 Psi, 15000 Psi, 20000 Psi |

| Seal Ring Material | PTFE, PVDF, DELRIN, PEEK, GRAPHITE |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design Standards | Valve Body – ASME B 16.34 Valve Flanges – ASME 16.5 Face to Face – ASME B 16.10 (long pattern) |

| End Connection | Flanged End / Screwed End / Butt Weld End / Screwed to BSPT / NPT / Socket Weld / Buttweld with extended Nipple |

| Ball Valve Type | One Piece, Two Piece, Three Piece, 3 Way, 4 Way, High temperature, fire safe, trunnion mounted Full Bore, Metal Seated, separate ball and shaft, split body design, pneumatically operated ball valve with Manual Over ride and gas purging provision. |

| Media Temperature | (-120* C To 500*C )Range As Per Pressure |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

| Application | Material Handling Equipment, Earth Moving Machineries , Power Generating Plant , Steel Manufacturing Plant , Mining Industries , Chemical Processing Machines , Piping Line , Paint Industries , Trucks And Trailers , Automation , Agriculture Machines , Aerospace & Defence Equipments |

Nickel Alloy 200 / 201 Ball Valves Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | – | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

Most Commonly used Nickel Alloy 200 / 201 Ball Valves Types

Nickel Alloy 200 / 201 2 Way Ball Valve

Nickel Alloy 200 / 201 3 Way Ball Valve

Nickel Alloy 200 / 201 4 Way Ball Valve

Nickel Alloy 200 / 201 5 Way Ball Valve

Nickel Alloy 200 / 201 Panel Mounted Ball Valve

Nickel Alloy 200 / 201 Butterfly Handle Ball Valve

Nickel Alloy 200 / 201 Short Handle Ball Valve

Nickel Alloy 200 / 201 Round Body Ball Valve

Nickel Alloy 200 / 201 Square Body Ball Valve

Nickel Alloy 200 / 201 Full Bore Ball Valve

Nickel Alloy 200 / 201 Reduced Bore Ball Valve

Nickel Alloy 200 / 201 Compression Ball Valve

Dimensions Of Alloy 200 / 201 Instrumentation Ball Valves

| END CONNECTION SIZE | ORIFICE | A | |||

|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) |

| 1/8 | 3.17 | 0.09 | 2.4 | 1.01 | 25.5 |

| 3/16 | 4.76 | 0.13 | 3.2 | 1.1 | 28 |

| 1/4 | 6.35 | 0.19 | 4.8 | 1.2 | 30 |

| 3/8 | 9.52 | 0.28 | 7.1 | 1.45 | 36.5 |

| 1/2 | 12.7 | 0.41 | 10.3 | 1.74 | 44.2 |

| 0.12 | 3 | 0.09 | 2.4 | 1.01 | 25.5 |

| 0.24 | 6 | 0.19 | 4.8 | 1.2 | 30 |

| 0.31 | 8 | 0.19 | 4.8 | 1.23 | 31.2 |

| 0.39 | 10 | 0.28 | 7.1 | 1.45 | 36.5 |

| 0.47 | 12 | 0.41 | 10.3 | 1.74 | 44.2 |

| B | C | D | |||

|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) |

| 1.01 | 25.5 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.1 | 28 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.2 | 30 | 1.47 | 37.3 | 0.78 | 19.8 |

| 1.45 | 36.5 | 2.07 | 52.5 | 1.13 | 28.7 |

| 1.74 | 44.2 | 2.44 | 62 | 1.5 | 38.1 |

| 1.01 | 25.5 | 1.36 | 34.5 | 0.59 | 15.1 |

| 1.2 | 30 | 1.47 | 37.3 | 0.59 | 15.1 |

| 1.23 | 31.2 | 1.47 | 37.3 | 0.78 | 19.8 |

| 1.45 | 36.5 | 2.07 | 52.5 | 1.13 | 28.7 |

| 1.74 | 44.2 | 2.44 | 62 | 1.5 | 38.1 |

| E | W | F | CV |

|||

|---|---|---|---|---|---|---|

| (IN) | (MM) | (IN) | (MM) | (IN) | (MM) | |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.15 |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.35 |

| 1/4 | 6.4 | 1.26 | 32 | 0.78 | 19.8 | 0.9 |

| 3/8 | 9.7 | 1.5 | 38.1 | 1.12 | 28.5 | 2 |

| 3/8 | 9.7 | 2.36 | 60 | 1.5 | 38 | 4.6 |

| 1/4 | 6.4 | 1.26 | 32 | 0.58 | 14.7 | 0.15 |

| 1/4 | 6.4 | 1.26 | 32 | 0.78 | 19.8 | 0.9 |

| 1/4 | 9.7 | 1.5 | 38.1 | 0.78 | 19.8 | 0.9 |

| 3/8 | 9.7 | 1.7 | 43 | 1.12 | 28.5 | 2 |

| 3/8 | 9.7 | 2.36 | 60 | 1.5 | 38 | 4.6 |

Other Related Products

Test Certificates Of Nickel Alloy 200 / 201 Ball Valves

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of Alloy 200 / 201 Instrumentation Ball Valves

- Nickel Alloy 200 Instrument Ball Valve

- Nickel Alloy 201 Three Piece Ball Valve

- Alloy 200 Instrumentation Ball Valves

- 201 Nickel Alloy High Pressure Ball Valves

- Nickel 200 Three Way Ball Valve Supplier

- 200 Nickel Alloy Hydraulic Ball Valves

- Nickel 201 Forged Ball Valve

- DIN 2.4066 3 Piece Ball Valves

- Nickel Alloy 200 Floating Ball Valves

- Alloy 200 Swagelok Ball Valves Stockist

- UNS N02200 2 Piece Ball Valves

- Alloy 201 1 Piece Ball Valves Exporter

- Nickel Alloy 200 Instrumentation Ball Valves

- Nickel JIS NW 2200 Single-piece Ball Valve

- Nickel 201 Panel Mount Ball Valves

- Nickel Alloy 200 One-Piece Ball Valves

- Nickel 201 High Pressure Instrument Ball Valve

- Alloy 200 Sanitary Ball Valves Distributor

- Nickel Alloy 200 Three Piece Bolted Ball Valve

- Nickel 201 Five-Way Ball Valves

- Nickel 200 Three Piece Firesafe Ball Valve

- Nickel Alloy 200 Industrial Ball Valves Price

- UNS N02201 Rising Stem Ball Valve

- Nickel Alloy 201 4 Way Ball Valve

- Nickel Alloy 201 Lined Ball Valve

- Alloy 200 Three Piece Compression Ended Ball Valve

- Nickel Alloy 200 3 Pc Ball Valve Dealer

- 200 Nickel Three Piece High Pressure Ball Valve

- DIN 2.4068 Multiport Ball Valves

- Nickel 201 High Pressure 2 Way Ball Valve

- Nickel Alloy 200 2-Piece Instrumentation Ball Valve

- Nickel Alloy 201 4 Way Ball Valves Manufacturer

- 201 Nickel Alloy Trunnion Ball Valves

- UNS N02200 Socket Weld End Ball Valve

Chemical Composition of Nickel 200 / 201 Instrumentation Ball Valves

| Grade | Ni | Fe | Cu | C | Mn | S | Si |

| 200 | 99.0 min | 0.40 | 0.25 | 0.15 | 0.35 | 0.01 | 0.35 |

| 201 | 99.0 min | 0.40 | 0.25 | 0.02 | 0.35 | 0.01 | 0.35 |

Mechanical Properties of Nickel Alloy 200 / 201 Ball Valve

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200/201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

Nickel Alloy 200 / 201 Ball Valves Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment

Nickel 200 / 201 Instrumentation Ball Valves Export Countries

Nickel Alloy Instrumentation Ball Valves

Instrumentation Ball Valves

- Stainless Steel Instrumentation Ball Valves

- Duplex Steel Instrumentation Ball Valves

- Super Duplex Instrumentation Ball Valves

- Inconel Instrumentation Ball Valves

- Monel Instrumentation Ball Valves

- Nickel Alloy Instrumentation Ball Valves

- Hastelloy Instrumentation Ball Valves

- Titanium Instrumentation Ball Valves

- Copper Nickel Instrumentation Ball Valves

- Other Instrumentation Ball Valves