Nickel Alloy 200 / 201 Tube Plug

Nickel Alloy 200 Tapered Tube Plug, Nickel 200 Tube Plug, Suppliers of Nickel Alloy 201 Heat Exchanger Tube Plug, 201 Nickel Two-Piece Tube Plug Manufacturer India, Alloy 200 Header Plug, Nickel 201 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a popular supplying unit of Nickel Alloy 200 / 201 Tube Plug, which are nicely appropriate for shaped or fabricated applications.

It is a variant and varies via way of having a decrease content material of Carbon in addition to decrease tensile and yield strengths to a point. Associated to nickel-chromium austenitic alloys, Nickel Alloy UNS N02200 Tube Plug presents advanced creep, tensile power and strain to rupture at excessive temperatures. It is an austenitic alloy, wherein it’s far as nicely alloyed with the aid of boron and nitrogen content material in it. However, those boron and nitrogen alloying necessities get better the mechanical houses at excessive temperatures.

Nickel 200 Expansion Tube Plug, UNS N02200 Tube Plug, UNS N02201 Metal Tapered Tube Plugs, Nickel Alloy 200 High Pressure Tube Plug, 2.4066 Tube Plug, DIN 2.4068 Condenser Tube Plug Supplier, Alloy 201 One-Piece Tube Plug Stockist, Nickel 201 Boiler Tube Plug Manufacturer In India.

- Material Specification Chart Of Nickel Alloy 200 / 201 Tube Plug

- Nickel Alloy 200 / 201 Tube Plug Equivalent Grade

- Most Commonly used Nickel Alloy 200 / 201 Tube Plug Types

- Nickel Alloy 200 / 201 Tube Plug Sizes

- Nickel Alloy 200 / 201 Threaded Tapered Plug Sizes

- Nickel Alloy 200 / 201 Two-Piece Metal Tube Plug Sizes

- Stock List Of Nickel Alloy 200 / 201 Tube Plug

- Chemical Composition of Alloy 200 / 201 Tube Plug

- Mechanical Properties of Nickel Alloy 200 / 201 Tube Plug

- Nickel Alloy 200 / 201 Tube Plug Uses and Application

- Nickel Alloy 200 / 201 Tube Plug Export Countries

It is an advanced carbon variant making the metal extra suitable to be used in capabilities wherein excessive temperatures are in attendance. Nickel Alloy UNS N02201 Tube Plug additionally provide strain-to-rupture, tensile power and better creep at excessive temperatures, wonderful corrosion resistance and efficiency houses. The molybdenum content material offers more suitable entire corrosion resistant attributes, in particular advanced resistance to crevice and pitting corrosion in chloride atmospheres.

The features of it are pretty equal to the ones of different alloys, other than that this metal is more potent to a point at excessive temperatures. Nickel Alloy WNR 2.4066 Tube Plug are used at temp as much as 1150 Deg C in incessant service, and 1035 Deg C in discontinuous service. Cyclic bureaucracy condense its oxidation resistance, and a thoroughgoing purposeful temperature of 1900 Deg F is typically recommended if biking is complicated.

They are basically non-magnetic as annealed and grow to be nonchalantly magnetic while bloodless functioned. It is usually carried out within the enterprise of car alongside heavy system industries. Nickel Alloy WNR 2.4068 Tube Plug is flexible and low cost corrosion resistant metal suitable for an intensive variety of not unusual place motive capabilities. The prudently measured chemical compositions provide a huge array of bloodless paintings hardenability, permitting them to ensemble for some of capabilities via way of direct drawing disadvantaged of transitional annealing.

Material Specification Chart Of Nickel Alloy 200 / 201 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Nickel Alloy 200 / 201 Tube Plug Equivalent Grade

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Nickel 200 | N02200 | 2.4066 | N-100M | Ni 99.2 | NW 2200 | NA 11 | НП-2 |

| Nickel 201 | N02201 | 2.4068 | – | LC-Ni 99 | NW 2201 | NA 11 | НП-2 |

Most Commonly used Nickel Alloy 200 / 201 Tube Plug Types

Nickel Alloy 200 / 201 Tapered Tube Plug

Nickel Alloy 200 / 201 Heat Exchanger Tube Plug

Nickel Alloy 200 / 201 Threaded Tapered Plug

Nickel Alloy 200 / 201 One-Piece Tube Plug

Nickel Alloy 200 / 201 Two-Piece Tube Plug

Nickel Alloy 200 / 201 Metal Tapered Tube Plug

Nickel Alloy 200 / 201 Expandable Tube Plug

Nickel Alloy 200 / 201 Boiler Tube Plug

Nickel Alloy 200 / 201 Tube Plug Sizes

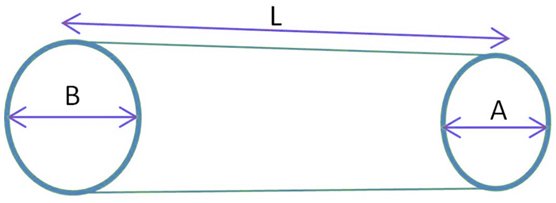

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Nickel Alloy 200 / 201 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Nickel Alloy 200 / 201 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Nickel Alloy 200 / 201 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Alloy 200 / 201 Tube Plug

| Grade | Ni | Fe | Cu | C | Mn | S | Si |

| 200 | 99.0 min | 0.40 | 0.25 | 0.15 | 0.35 | 0.01 | 0.35 |

| 201 | 99.0 min | 0.40 | 0.25 | 0.02 | 0.35 | 0.01 | 0.35 |

Mechanical Properties of Nickel Alloy 200 / 201 Tube Plug

| Grade | Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| Alloy 200/201 | 8.9 g/cm3 | 1446 °C (2635 °F) | Psi – 21500 , MPa – 148 | Psi – 67000 , MPa – 462 | 45 % |

Nickel Alloy 200 / 201 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment