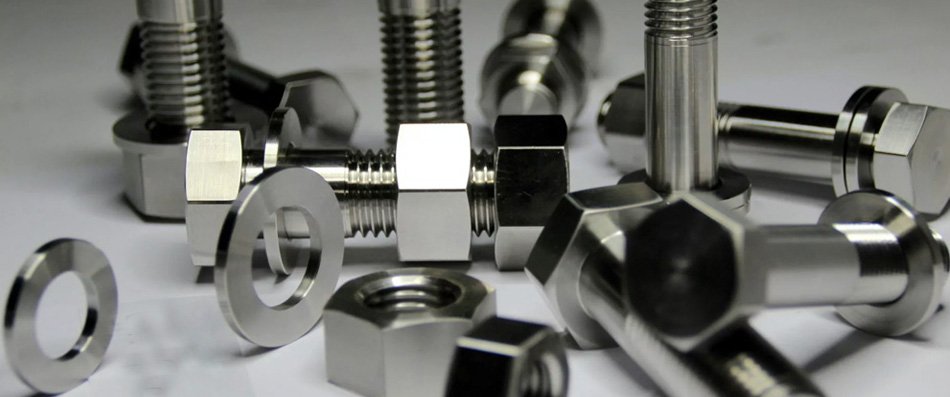

Nitronic Fasteners

Nitronic 50 Fasteners, Nitronic Bolts, Suppliers of Nitronic Nuts, Nitronic Stud Bolts, Stainless Steel Nitronic Screws, Nitronic® 60 Fasteners At Factory Price In India.

Stainless Steel Nitronic Bolts, Nitronic 40 Anchor Fasteners, Nitronic 32 Machine Screw Stockist, 1.3964 Threaded Rod Supplier, UNS S21800 Fasteners, UNS S20910 Bolts, Alloy 218 Socket Set Screw Manufacturer In India.

- Material Specification Chart Of Nitronic Fasteners

- Nitronic Fasteners Equivalent Grade

- Most Commonly used Nitronic Fasteners Types

- Nitronic Fasteners Standard

- Dimensions Of Nitronic Bolts

- Nitronic Fasteners Torque Chart

- Weight Chart Of Nitronic Fasteners

- Stock List Of Nitronic Fasteners

- Chemical Composition of Nitronic Fasteners

- Mechanical Properties of Nitronic Fasteners

- Nitronic Fasteners Uses and Application

- Nitronic Fasteners Export Countries

Because this alloy incorporates no huge chromium addition, it must now no longer be utilized in oxidizing media or in presence of oxidizing salts, inclusive of ferric or cupric salts. Nitronic Bolts is appropriate to be used in diverse situations which includes a lot of non – oxidizing acids. They are used for lots packages which includes strain vessels, chemical reactors, nuclear reactors, as pipes and valves in chemical industry. Fasteners with confined chemistry may be used within the welded circumstance and is much less liable to SCC below many situations.

Nitronic Washers may be rolled to attain the mood houses required with the aid of using unique clients and/or production requirements. Principal high-temperature makes use of for Fasteners are the ones wherein a low coefficient of thermal growth is required. Ferric or cupric salts for Fasteners can also additionally broaden whilst hydrochloric acid comes in touch with iron or copper. As always, care should be taken in selecting Fasteners for the preferred application. It must be answer annealed at 1950 Degree F (1040 Degree C) and swiftly quenched. It must now no longer be utilized in oxidizing media or in which oxidizing contaminants are to be had in decreasing media. Surface situation for maximum corrosion resistance is pickled or machined.

Material Specification Chart Of Nitronic Fasteners

| Specification | ASTM A193 / ASME SA193 |

|---|---|

| Standard | DIN, UNI, ISO, JIS, GB, IS, BS, ASME, ANSI, ASTM and all International Standards |

| Size | M2, M2.5, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M24, M30, M36 to M160 |

| Length | 3 mm to 200 mm |

| Threads | METRIC, BSW, BSF, UNC, UNF or as required |

| Standard | ANSI – American National Standards Institute

DIN: DIN 931, DIN 933, DIN 934, DIN 970 UTS – Unified Thread Standard : UNC, UNF, UNEF, UNS, NPT, NPTF ISO – International Organization for Standardization : ISO 4032, ISO 4033, JIS standards |

| In Form of | Hex, Square, Round, Threading as per Gauge Etc. |

| Head drive | Phillips, Slotted, Phillips/Slot, Six-Lobe, etc |

| Test Certificate: | Manufacturer Test Certificate as per EN 10204 / 3.1 |

| Surface finishing | Zinc (yellow, white, blue, black), black oxide, Geometry, Dacroment, anodizing, nickel plated, plated zinc-nickel, Stainless steel: Passivated Self-Colour, Hot Dip Galvanised (HDG), Bright Zinc Plated (BZP), Sherardized, Stainless Steel, Mechanically Applied coating and some special one like DACROMET |

| Production process | M2-M24: Cold Froging, hot forging M24-M100, machining and CNC for Customized connecting element |

| Surface Coating |

All surface finishes offered including Geomet & PTFE, Galvanised, Zinc, Electroless Nickel, Sherardized, Dacromet |

| Packing | IN BULK: canton, pallet, Small Boxs / carton / pallet, or customer request |

Nitronic Fasteners Equivalent Grade

| STANDARD | Werkstoff Number | UNS | Alloy |

| Nitronic® 50 | 1.3964 | S20910 | Alloy XM-19 |

| Nitronic® 60 | – | S21800 | Alloy 218 |

Most Commonly used Nitronic Fasteners Types

Nitronic Bolts

- Nitronic 60 U Bolts

- Nitronic 32 Eye Bolts

- UNS S20910 Carriage Bolts

- Nitronic 50 Flange Bolts

- Nitronic Hex Head Bolt

- 1.3964 Square Bolts

- Stainless Steel Nitronic 40 Bolt

Nitronic Screw

- Nitronic Socket Head Cap Screw

- Nitronic® 32 Machine Screw

- 1.3964 Self Tapping Screw

- Nitronic 50 Allen Cap Screws

- UNS S20910 Self Tapping Screw

- Nitronic 60 Wood Screws

- Nitronic Screw

Nitronic Nuts

- 1.3964 Square Nuts

- Nitronic Coupling Nuts

- Nitronic 50 Heavy Hex Nuts

- UNS S20910 Wing Nuts

- Nitronic 60 Dome Nuts

- Nitronic® 50 Nuts

- Nitronic® 40 Stainless Steel Hex Nuts

Nitronic Stud Bolts

- 1.3964 Half Threaded Stud Bolt

- Nitronic 60 Tap End Stud Bolt

- Nitronic 50 Double Ended Stud Bolts

- Nitronic Tie Rods

- UNS S20910 Stud Bolt

- Nitronic 40 Stud Bolt

- Stainless Steel Nitronic Stud Bolt

Nitronic Washer

- Stainless Steel Nitronic Washers

- Nitronic 32 Plain Washer

- 1.3964 Square Washer

- Nitronic 60 Split Washer

- UNS S20910 Spring Washer

- Nitronic 50 Flat Washer

- Nitronic 40 Ogee Washer

Nitronic Anchor Bolts

- Nitronic 40 Sleeve Anchor Bolts

- 1.3964 Self Tapping Anchor

- Nitronic 60 Concrete Anchor

- UNS S20910 Wedge Anchor Bolt

- Nitronic J Anchor Bolts

- Nitronic 32 Anchor Bolt

- Nitronic 50 Anchor Bolt

Nitronic Threaded Rod

- UNS S20910 Half Threaded Rods

- 1.3964 Trapezoidal Threaded Rod

- Nitronic Heavy Threaded Rods

- Nitronic 50 Acme Threaded Rods

- Nitronic 40 Full Threaded Rods

- Stainless Steel Nitronic Threaded Rod

- Nitronic 60 Partially Threaded Rods

Nitronic Stud

- Nitronic Stainless Steel Studs

- Nitronic 60 Full Thread Stud

- UNS S20910 Double Ended Stud

- Nitronic® 50 Flush Head Studs

- Stainless Steel Nitronic Stud

- 1.3964 Studs

Nitronic Fasteners Standard

| Hexagon Bolt / Set Screws | Stud Bolt | Hexagon Nuts | Socket Cap screws |

|---|---|---|---|

| DIN 931 | BS4882 | DIN 934 | DIN 912 |

| DIN 933 | DIN 976 | BS 1768 | DIN 6912 |

| BS 1768 | BS 1769 | DIN 7984 | |

| UNI 5731 | BS 1083 | ANSI B18.3 | |

| UNI 5739 | BS 3692 | ISO 4762 | |

| ISO 4014 | ISO 4032 | UNI 5931 | |

| ISO 4017 | ISO 4033 | BS 2470 | |

| BS 1769 | ANSI B18.2.2 | BS 4168 | |

| BS 3692 | |||

| ANSI B18.2.1 | |||

| Socket & Slotted Set Screws | Socket & Slotted Countersunk Screws | Studs | Washers |

| DIN 913 | DIN 963 | DIN 938 | DIN 125 |

| DIN 914 | DIN 7991 | DIN 939 | DIN 9021 |

| DIN 915 | BS 4168 | DIN 2510 | BS 4320 |

| DIN 916 | BS 1981 | BS 4439 | BS 3410 |

| DIN 551 | BS 483 | BS 2693 | |

| DIN 553 | BS 2470 | Spring Washers | |

| DIN 438 | DIN 127 | ||

| BS 4168 | BS 4464 | ||

| BS 1802 |

ANSI And/Or ASME Standards Nitronic Fasteners Inch Series

| ASME B18.1.1 | Small Solid Rivets | ASME B18.8.1 | Clevis Pins and Cotter Pins |

|---|---|---|---|

| ASME B18.1.2 | Large Rivets | ASME B18.8.2 | Taper Pins, Dowel Pins, Straight Pins, Grooved Pins and Spring Pins |

| ASME B18.2.1 | Square and Hex Bolts and Screws | ASME B18.9 | Plow Bolts |

| ASME B18.2.2 | Square and Hex Nuts | ASME B18.10 | Track Bolts and Nuts |

| ASME B18.2.6 | Fasteners for use in Structural Applications | ASME B18.11 | Miniature Screws |

| ASME B18.3 | Socket Cap, Shoulder and Set Screws | ASME B18.13 | Screws and Washer Assemblies (Sems) |

| ASME B18.5 | Round Head Bolts | ASME B18.15 | Forged Eyebolts |

| ASME B18.6.2 | Slotted Head Cap Screws, Square Head Set Screws, and Slotted Headless Set Screws | ASME B18.17 | Wing Nuts, Thumb Screws and Wing Screws |

| ASME B18.6.3 | Machine Screws and Machine Screws Nuts | ASME B18.21.1 | Lock Washers |

| ASME B18.6.4 | Thread Forming and Thread Cutting Tapping Screws and Metallic Drive Screws | ASME B18.22.1 | Plain Washers |

| ASME B18.7 | General Purpose Semi- Tubular Rivets, Full Tubular Rivets, Split Rivets and Rivet Caps | ASME B18.23.1 | Beveled Washers |

Other Related Products

Dimensions Of Nitronic Bolts

| NOMINAL SIZE (D) | BODY DIAMETER | HEAD THICKNEASTM A193 | ACROASTM A193 THE FLATS | ACROASTM A193 CORNERS | ||||

|---|---|---|---|---|---|---|---|---|

| D (MAX) | D (MIN) | H (MAX) | H (MIN) | F (MAX) | F (MIN) | C (MAX) | C (MIN) | |

| m10 | 10.00 | 9.78 | 6.63 | 6.17 | 17.00 | 15.73 | 18.48 | 17.77 |

| m12 | 12.00 | 11.73 | 7.76 | 4.24 | 19.00 | 17.73 | 20.78 | 20.03 |

| m14 | 14.00 | 13.73 | 9.09 | 8.51 | 22.00 | 20.67 | 24.25 | 23.35 |

| m16 | 16.00 | 15.73 | 10.32 | 9.68 | 24.00 | 23.67 | 27.71 | 26.75 |

| m20 | 20.00 | 19.67 | 12.88 | 12.12 | 30.00 | 29.16 | 34.64 | 32.95 |

| m24 | 24.00 | 23.67 | 15.44 | 14.56 | 36.00 | 35.00 | 41.57 | 39.55 |

| m30 | 30.00 | 29.67 | 19.48 | 17.92 | 46.00 | 45.00 | 53.12 | 50.85 |

| m36 | 36.00 | 35.61 | 23.38 | 21.63 | 55.00 | 53.80 | 63.51 | 60.79 |

| m42 | 42.00 | 41.38 | 26.97 | 25.03 | 65.00 | 62.90 | 75.06 | 71.71 |

| m48 | 48.00 | 47.38 | 31.07 | 28.93 | 75.00 | 72.60 | 86.60 | 82.76 |

| m56 | 56.00 | 55.26 | 36.2 | 33.80 | 85.00 | 82.20 | 98.15 | 93.71 |

| m64 | 64.00 | 63.26 | 41.32 | 38.68 | 95.00 | 91.80 | 109.70 | 104.65 |

| m72 | 72.00 | 71.26 | 46.45 | 43.55 | 105.00 | 101.40 | 121.24 | 115.60 |

| m80 | 80.00 | 79.26 | 51.58 | 48.42 | 115.00 | 111.00 | 132.72 | 126.54 |

| m90 | 90.00 | 89.13 | 57.74 | 54.26 | 130.00 | 125.50 | 150.11 | 143.07 |

| m100 | 90.00 | 99.13 | 63.9 | 60.10 | 145.00 | 140.00 | 167.43 | 159.60 |

Nitronic Fasteners Torque Chart

| Torque Specifications | |||||||

|---|---|---|---|---|---|---|---|

| Bolt Size Inches or # | Threads Per Inch | Standard Dry Torque in Inch-Pounds | |||||

Nitronic | Nitronic | ||||||

| #2 | 56 | 2.5 | 2.6 | ||||

| 64 | 3.0 | 3.2 | |||||

| #3 | 48 | 3.9 | 4.0 | ||||

| 56 | 4.4 | 4.6 | |||||

| #4 | 40 | 5.2 | 5.5 | ||||

| 48 | 6.6 | 6.9 | |||||

| #5 | 40 | 7.7 | 8.1 | ||||

| 44 | 9.4 | 9.8 | |||||

| #6 | 32 | 9.6 | 10.1 | ||||

| 40 | 12.1 | 12.7 | |||||

| #8 | 32 | 19.8 | 20.7 | ||||

| 36 | 22.0 | 23.0 | |||||

| #10 | 24 | 22.8 | 23.8 | ||||

| 32 | 31.7 | 33.1 | |||||

| Bolt Size Inches or # | Threads Per Inch | Standard Dry Torque in Inch-Pounds | |||||

| Nitronic | Nitronic | ||||||

| 1/4 | 20 | 75.2 | 78.8 | ||||

| 28 | 94.0 | 99.0 | |||||

| 5/16 | 18 | 132 | 138 | ||||

| 24 | 142 | 147 | |||||

| 3/8 | 16 | 236 | 247 | ||||

| 24 | 259 | 271 | |||||

| 7/16 | 14 | 376 | 393 | ||||

| 20 | 400 | 418 | |||||

| 1/2 | 13 | 517 | 542 | ||||

| 20 | 541 | 565 | |||||

| Bolt Size Inches or # | Threads Per Inch | Standard Dry Torque in Inch-Pounds | |||||

| Nitronic | Nitronic | ||||||

| 9/16 | 12 | 682 | 713 | ||||

| 18 | 752 | 787 | |||||

| 5/8 | 11 | 1110 | 1160 | ||||

| 18 | 1244 | 1301 | |||||

| 3/4 | 10 | 1530 | 1582 | ||||

| 16 | 1490 | 1558 | |||||

| 7/8 | 9 | 2328 | 2430 | ||||

| 14 | 2318 | 2420 | |||||

| 1 | 8 | 3440 | 3595 | ||||

| 14 | 3110 | 3250 | |||||

| Bolt Size Inches or # | Threads Per Inch | Standard Dry Torque in Foot-Pounds | |||||

| Nitronic | Nitronic | ||||||

| 1 1/8 | 7 | 413 | 432 | ||||

| 12 | 390 | 408 | |||||

| 1 1/4 | 7 | 523 | 546 | ||||

| 12 | 480 | 504 | |||||

| 1 1/2 | 6 | 888 | 930 | ||||

| 12 | 703 | 732 | |||||

Weight Chart Of Nitronic Fasteners

| AS PER IS 1363/67 MM THREADS | ||||||||||

| FOR 100 NOS APPROXIMATE WEIGHT IN KGS | ||||||||||

| LENGTH | Fasteners DIAMETER | |||||||||

| M 6 | M 5 | M 8 | M 12 | M 10 | M 14 | M 18 | M 22 | M 16 | M 20 | |

| 16 mm | 0.743 | 0.448 | 1.590 | 3.211 | ||||||

| 20 mm | 0.812 | 0.598 | 1.711 | 4.892 | 3.411 | |||||

| 25 mm | 0.897 | 0.660 | 1.871 | 5.252 | 3.660 | 8.170 | ||||

| 30 mm | 1.010 | 0.737 | 2.070 | 5.574 | 3.912 | 9.690 | 10.707 | 18.657 | ||

| 35 mm | 1.120 | 0.804 | 2.271 | 5.974 | 4.223 | 10.000 | 16.026 | 11.416 | 19.608 | |

| 40 mm | 1.230 | 0.881 | 2.470 | 6.410 | 4.533 | 10.288 | 16.667 | 12.107 | 20.747 | |

| 45 mm | 1.340 | 0.958 | 2.671 | 6.859 | 4.840 | 10.504 | 17.241 | 12.821 | 21.739 | |

| 50 mm | 1.450 | 1.030 | 2.870 | 7.299 | 5.155 | 11.261 | 17.857 | 28.409 | 13.624 | 22.727 |

| 55 mm | 1.560 | 3.071 | 7.740 | 5.464 | 11.628 | 18.868 | 30.120 | 14.409 | 23.810 | |

| 60 mm | 1.670 | 3.270 | 8.183 | 5.774 | 12.255 | 20.000 | 32.051 | 15.244 | 25.126 | |

| 65 mm | 1.781 | 3.472 | 8.621 | 6.083 | 12.626 | 21.008 | 34.014 | 16.026 | 26.455 | |

| 70 mm | 1.890 | 3.671 | 9.058 | 6.394 | 12.987 | 22.124 | 35.461 | 16.835 | 27.778 | |

| 75 mm | 2.000 | 3.873 | 9.506 | 6.702 | 13.228 | 23.256 | 39.063 | 17.606 | 29.070 | |

| 80 mm | 2.111 | 4.072 | 10.000 | 7.013 | 13.889 | 24.510 | 40.000 | 18.248 | 30.303 | |

| 90 mm | 4.472 | 10.917 | 7.634 | 14.925 | 26.042 | 41.667 | 19.841 | 33.113 | ||

| 100 mm | 4.873 | 11.820 | 8.251 | 16.340 | 27.778 | 46.296 | 21.459 | 35.714 | ||

| 110 mm | 12.723 | 8.881 | 17.730 | 31.250 | 47.170 | 23.041 | 38.168 | |||

| 120 mm | 13.624 | 9.506 | 18.797 | 32.895 | 50.000 | 24.631 | 40.984 | |||

| 130 mm | 14.535 | 10.101 | 20.000 | 34.722 | 52.632 | 26.316 | 43.478 | |||

| 140 mm | 15.432 | 10.707 | 20.833 | 35.461 | 55.556 | 27.933 | 46.296 | |||

| 150 mm | 16.340 | 11.312 | 22.222 | 37.594 | 58.824 | 29.412 | 48.544 | |||

| 160 mm | 17.241 | 11.905 | 24.272 | 40.984 | 61.728 | 31.056 | 50.505 | |||

| 170 mm | 18.116 | 12.500 | 64.935 | 32.680 | 53.191 | |||||

| 180 mm | 19.011 | 13.123 | 26.882 | 67.568 | 34.247 | 55.556 | ||||

| 190 mm | 19.920 | 13.736 | 70.423 | 35.971 | 58.140 | |||||

| 200 mm | 20.833 | 14.327 | 29.586 | 49.020 | 73.529 | 37.594 | 60.976 | |||

| 220 mm | 22.624 | 15.528 | 79.365 | 40.650 | 65.789 | |||||

| 240 mm | 24.510 | 16.722 | 84.746 | 43.860 | 71.429 | |||||

| 250 mm | 25.381 | 17.301 | 87.719 | 45.455 | 74.627 | |||||

| 260 mm | 26.316 | 17.921 | 90.909 | 47.170 | 76.923 | |||||

| 280 mm | 28.090 | 19.157 | 98.039 | 50.505 | 81.967 | |||||

| 300 mm | 29.940 | 20.325 | 104.167 | 53.763 | 87.719 | |||||

| 320 mm | 31.646 | 56.818 | 92.593 | |||||||

| 340 mm | 33.557 | 60.241 | 98.039 | |||||||

| 360 mm | 35.211 | 63.291 | 104.167 | |||||||

| 380 mm | 37.037 | 66.667 | 108.696 | |||||||

| 400 mm | 39.063 | 69.444 | 113.636 | |||||||

Test Certificates Of Nitronic Fasteners

- Mill Test Report

- Raw Materials Certificate

- EN 10204/3.1B

- Third Party Inspection Report

- 100% Radiography Test Report

Chemical Composition of Nitronic Fasteners

| Nitronic 32 / 40 / 50 /60 | |

| Carbon | 0.15 max |

| Chromium | 16.5 – 19.5 |

| Iron | Balance |

| Manganese | 11 – 14 |

| Nickel | 0.5 – 2.5 |

| Nitrogen | 0.2 – 0.45 |

| Phosphorus | 0.06 max |

| Silicon | 1 max |

| Sulphur | 0.03 max |

Mechanical Properties of Nitronic Fasteners

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength, ultimate | 883 MPa | 128000 psi |

| Tensile strength, yield (@0.2%) | 745 MPa | 108000 psi |

| Elongation at break (in 50 mm) | 56% | 56% |

| Modulus of elasticity (typical for stainless steel) | 200 GPa | 29000 ksi |

Nitronic Fasteners Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment

Nitronic Fasteners Export Countries

SS Special Grades

- ASTM A453 Gr 660 Fasteners

- 1.4980 Fasteners

- Stainless Steel XM19 Fasteners

- SMO 254 Fasteners

- Stainless Steel 904L Fasteners

- DIN Fasteners

- Nitronic Fasteners

- PTFE / TEFLON Coated Fasteners

- Xylan Coated Fasteners

- Phosphorous Bronze Fasteners

- Silicon Bronze Fasteners

- Aluminium Bronze Fasteners

- Hot Dip Galvanized Fasteners

- ASTM A193 Grade B7 Fasteners

- High Tensile Grade 8.8 Fasteners

- High Tensile Grade 10.9 Fasteners

- High Tensile Grade 12.9 Fasteners