SMO 254 Needle & Gauge Valve

Alloy 254 High Pressure Needle Valve Manufacturer, Suppliers of 254 SMO Hydraulic Needle Valve, 254 SMO Stainless Steel Integral Bonnet Needle Valve, SMO 254 Compression Needle Valve, SMO 254 Needle & Gauge Valve At Factory Price In India.

Vintex Steel & Engg. Co. is manufacturer of SMO 254 Needle Valves & Gauge Valves, which possesses a degree of aqueous corrosion resistance akin to that of the austenitic stainless steels.

In addition, its miles austenitic metal making it ideal for manifold machineries within the oil & fuelling industry, fastener programs. Typical Applications include: Jet engine components, Non-magnetic cryogenic equipment, High temperature fasteners, spring, etc. We offer these SMO 254 Forged Needle & Gauge Valves in different sizes and shapes that are being designed as per the national and international standard quality of raw materials. All SMO 254 needles valves are developed to provide superior performances in those industrial applications that demand rugged as well as reliable performances.

Alloy 254 Panel Mount Needle Valve, 254 SMO Instrumentation Needle Valve, 254 SMO Miniature Needle Valve, Stainless Steel SMO 254 Union Bonnet Needle Valve, DIN 1.4547 Hex Needle Valve Supplier, 6 Moly Miniature Needle Valve Stockist, 1/2 Inch SMO 254 Needle Valve, 1.4547 Needle Valve, UNS S31254 Gauge Valve, UNS S31254 Forged Needle Valve Manufacturer In India.

- Material Specification Chart Of 254 SMO Needle & Gauge Valve

- SMO 254 Needle & Gauge Valve Equivalent Grade

- Most Commonly used SMO 254 Needle & Gauge Valve Types

- Dimension Chart Of 254 SMO Needle & Gauge Valve

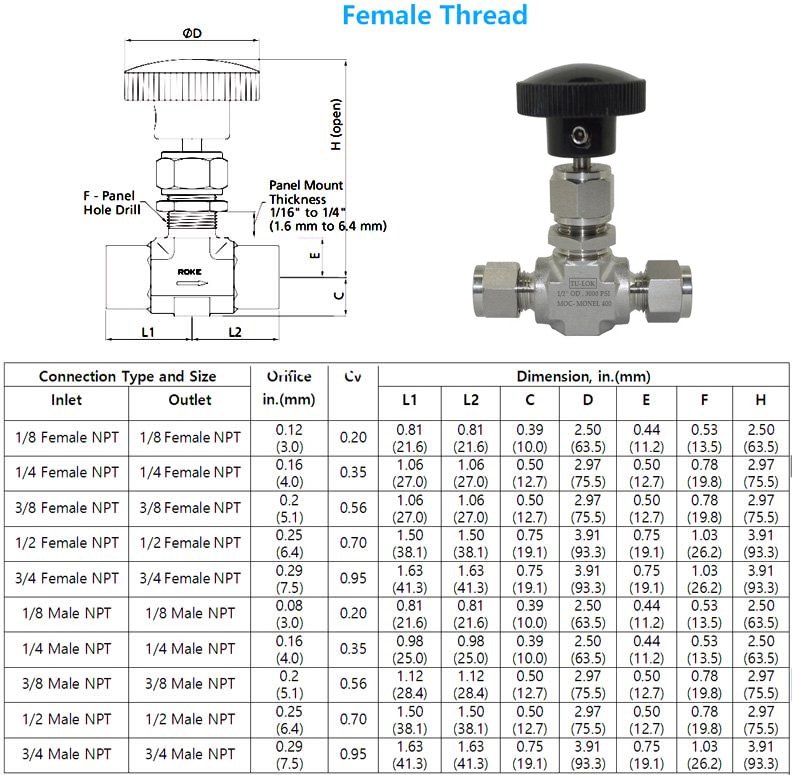

- 254 SMO Female Thread Needle Valve Dimensions Chart

- Stock List Of SMO 254 Needle & Gauge Valve

- Chemical Composition of 254 SMO Needle & Gauge Valve

- Mechanical Properties of SMO 254 Needle & Gauge Valve

- SMO 254 Needle & Gauge Valve Uses and Application

- SMO 254 Needle & Gauge Valve Export Countries

It is as nicely acceptable for expend to a temperature of approximately 1300 Deg F in corrosive environment (which includes fuelling turbines) and to 1500 Deg F for non-stop carrier in oxidizing environments. In fact, the notched rupture power of alloy is advanced to many different industrial alloys in company of the similar excessive temperature houses. It has excessive power to one thousand Degree F and Oxidation proof against 1500 Degree F. Alloy 254 Needle Valves is used for rationally cost-powerful whilst oxidation resistance and slight power are crucial at temperatures advanced to suitable for stainless steels.

Material Specification Chart Of 254 SMO Needle & Gauge Valve

| Size | 1/4″ to 1″ (Female / Female BSP and BSPT), 3/8″ to 1″ (Female / Female NPT) and 1/4″ to 1/2″ (Male / Female BSPP). |

| Thread | NPT, BSPP, BSPT, JIC, METRIC, UNF |

| Connection | Threaded, Tube End, Butt Weld, Socket Weld, Weld Nipple, Flanged, Sae |

| Function | 2 Way, 3 Way |

| Pressure Rating | 1500 PSI, 3000 PSI, 6000 PSI, 10000 PSI, 15,000 PSI, 20000 PSI |

| Orifice Size | 2 MM TO 9.5 MM |

| Standard | ISO , DIN , ANSI , API , ASME , AWWA , MSS |

| Design | Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

| Patterns | Straight / Angle |

| Needle Valve Type | Bar Stock Needle Valve, High Pressure Needle Valve, Angle Needle Valve, Union Bonnet High Pressure Female X-Female NPT, Miniature Needle Valve, Screwed Bonnet Needle Valve, Forged Needle Valve |

| Maximum Working Pressure | Up to 6000 psig (413 bar) |

| Equivalent Brands | Swagelok, Parker, Dk-Lok, Hamlet, Oliver Valves, Hoke |

SMO 254 Needle & Gauge Valve Equivalent Grade

| STANDARD | UNS | WNR. | AFNOR | SIS | JIS |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | 2378 |

Most Commonly used SMO 254 Needle & Gauge Valve Types

SMO 254 Screwed End Needle Valve

SMO 254 Tube End Needle Valve

SMO 254 Socket Weld Needle Valve

SMO 254 Angle Needle Valve

SMO 254 Hexagonal Needle Valve

SMO 254 3 Way Needle Valve

SMO 254 Union Bonnet Needle Valve

SMO 254 Panel Mounted Needle Valve

SMO 254 Forged Needle Valve

SMO 254 Miniature Needle Valve

SMO 254 High Pressure Needle Valve

SMO 254 Bar Stock Needle Valve

Dimension Chart Of 254 SMO Needle & Gauge Valve

| Size | L | a | b | W | H |

|---|---|---|---|---|---|

| 1/8″ | 56 | 28 | 28 | 60 | 80 |

| ¼” | 56 | 28 | 28 | 60 | 80 |

| 3/8” | 56 | 28 | 28 | 60 | 80 |

| ½” | 58 | 28 | 28 | 60 | 81 |

| ¾” | 62 | 35 | 35 | 60 | 85 |

| 1” | 70 | 45 | 45 | 70 | 100 |

| Port Size (BSP) | Media Pressure | Media Temperature | CV |

|---|---|---|---|

| 1/8″ | 0 to 408 Bar | -20°C to 230°C | |

| ¼” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| 3/8” | 0 to 408 Bar | -20°C to 230°C | 0.4 |

| ½” | 0 to 408 Bar | -20°C to 230°C | 0.6 |

| ¾” | 0 to 408 Bar | -20°C to 230°C | 1.6 |

| 1” | 0 to 408 Bar | -20°C to 230°C | 2.5 |

254 SMO Female Thread Needle Valve Dimensions Chart

Other Related Products

Test Certificates Of SMO 254 Needle & Gauge Valve

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Stock List Of SMO 254 Needle & Gauge Valve

- 6 Moly 3 Way Needle Valve

- Alloy 254 Angle Needle Valve

- Stainless Steel SMO 254 Compression Needle Valve

- DIN 1.4547 Threaded Needle Valve

- SMO 254 Flow Control Needle Valves

- SMO 254 High Pressure Needle Valve

- 6 Moly Flanged Needle Valve

- 254 SMO Integral Bonnet Needle Valve Stockist

- UNS S31254 Socket Weld End Needle Valve

- SMO 254 Gauge Valve

- Alloy 254 1rs4 Needle Valve

- Stainless Steel 254 SMO Gauge Valve

- 254 SMO 1/4 Needle Valve

- SMO 254 1/2 Inch Needle Valve

- Alloy 254 Screwed End Needle Valve Exporter

- 254 SMO Female Thread Needle Valve

- 254 SMO Hydraulic Needle Valve Supplier

- Alloy 254 Screwed Bonnet Valve

- 254 SMO Instrumentation Needle Valve

- SMO 254 Panel Mount Needle Valve

- SMO 254 Union Bonnet Needle Valve

- Alloy 254 Male Needle Valve Manufacturer

- Alloy 254 Miniature Needle Valve

- SMO 254 Industrial Needle Valve Price

- UNS S31254 Female Male Needle Valves

- SMO 254 Multi Port Gauge Needle Valve

- 254 SMO Single Port Gauge Needle Valve Dealer

- UNS S31254 Gauge Valve

- 6 Moly Straight Needle Valve

- Alloy 254 Hex Needle Valves

- DIN 1.4547 Bar Stock Needle Valve

- 254 SMO Round Body Needle Valve

- 254 SMO 90 Deg Angled Needle Valve

- 254 SMO Forged Needle Valve Distributor

Chemical Composition of 254 SMO Needle & Gauge Valve

| Grade | Ni | C | Mo | Mn | Si | F | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | – | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

Mechanical Properties of SMO 254 Needle & Gauge Valve

| Element | Density | Melting Point | Yield Strength (0.2%Offset | Tensile Strength | Elongation |

| SMO 254 | 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

SMO 254 Needle & Gauge Valve Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment