Stainless Steel 317 / 317L Tube Plug

Stainless Steel 317 Tapered Tube Plug, SS 317L Header Plug, Stainless Steel 317 Tube Plug, Suppliers of SS 317L Heat Exchanger Tube Plug, 317L SS Two-Piece Tube Plug Manufacturer India, Stainless Steel 317L Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is exporter and supplier of Stainless Steel 317 / 317L Tube Plug in India. They are pretty normally utilized in structural home equipment which consists of fasteners, gears, and some plane exterior. We offer this SS 317 / 317l Tube Plug Fittings in different sizes and thickness. We export and supply an extensive array of Stainless Steel 317 plug fittings that have excellent impact strength. Few properties of such Stainless Steel UNS S31700 Tube Plug are that it has a few awesome weldability, excessive decisive tensile strength, excessive yield strength, and so on.

SS 317L High Pressure Tube Plug, 317L SS One-Piece Tube Plug Stockist, Stainless Steel 317 Boiler Tube Plug, DIN 1.4438 Condenser Tube Plug Supplier, UNS S31700 Tube Plug, UNS S31703 Metal Tapered Tube Plugs, 317L SS Expansion Tube Plug, 1.4449 Tube Plug Manufacturer In India.

- Material Specification Chart Of Stainless Steel 317 / 317L Tube Plug

- Stainless Steel 317 / 317L Tube Plug Equivalent Grade

- Most Commonly used Stainless Steel 317 / 317L Tube Plug Types

- Stainless Steel 317 / 317L Tube Plug Sizes

- Stainless Steel 317 / 317L Threaded Tapered Plug Sizes

- Stainless Steel 317 / 317L Two-Piece Metal Tube Plug Sizes

- Stock List Of Stainless Steel 317 / 317L Tube Plug

- Chemical Composition of SS 317 / 317L Tube Plug

- Mechanical Properties of Stainless Steel 317 / 317L Tube Plug

- Stainless Steel 317 / 317L Tube Plug Uses and Application

- Stainless Steel 317 / 317L Tube Plug Export Countries

We have developed all ranges of product at the highly equipped inventory that is resulting in making those greatly reliable and durable as well. They are used specially in equipment element reducing and aren’t effects welded for the purpose that of its advanced carbon content material. They are commonly engaged in shafts, pins, rods, spindles, sprocket assemblies and a variety of element parts. It could be very tons perfect in numerous industries due to its extra efficiency and strength.

Material Specification Chart Of Stainless Steel 317 / 317L Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Stainless Steel 317 / 317L Tube Plug Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | – |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

Most Commonly used Stainless Steel 317 / 317L Tube Plug Types

SS 317 / 317L Tapered Tube Plug

SS 317 / 317L Heat Exchanger Tube Plug

SS 317 / 317L Threaded Tapered Plug

SS 317 / 317L One-Piece Tube Plug

SS 317 / 317L Two-Piece Tube Plug

SS 317 / 317L Metal Tapered Tube Plug

SS 317 / 317L Expandable Tube Plug

SS 317 / 317L Boiler Tube Plug

Stainless Steel 317 / 317L Tube Plug Sizes

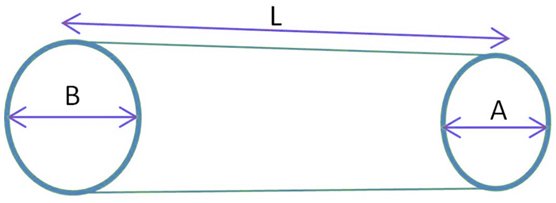

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Stainless Steel 317 / 317L Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Stainless Steel 317 / 317L Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Stainless Steel 317 / 317L Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of SS 317 / 317L Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 – 20.00 | 3.00 – 4.00 | 11.00 – 15.00 | 57.89 min |

Mechanical Properties of Stainless Steel 317 / 317L Tube Plug

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Stainless Steel 317 / 317L Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment