Stainless Steel 410 Tube Plug

Stainless Steel 410 Tapered Tube Plug, SS 410 Header Plug, Stainless Steel 410 Tube Plug, 410 SS Two-Piece Tube Plug Manufacturer India, Suppliers of SS 410 Heat Exchanger Tube Plug, Stainless Steel 410 Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is exporter and upplier of SS 410 Tube Plug in India. Stainless steel 410 tube plugs are typically used to seal the end of a tube or pipe in applications where a leak-proof seal is required. The 410 stainless steel material is a martensitic stainless steel that offers good corrosion resistance and high strength. It is one of the high-quality steels advanced for max resistance to acid attack. And due to this feature, there are numerous makes use of for it in each the immaculate and nickel industries. These Stainless Steel 410 Tube Plugs cannot be hardened by heat treatment, only by cold working. Stainless Steel 410 Tube Plug can be easily welded and processed by standard shop fabrication practices.

SS 410 High Pressure Tube Plug, 1.4006 Tube Plug, UNS S41000 Tube Plug, Stainless Steel 410 Boiler Tube Plug, 410 SS One-Piece Tube Plug Stockist, 410 SS Expansion Tube Plug, DIN 1.4006 Condenser Tube Plug Supplier, UNS S41000 Metal Tapered Tube Plugs Manufacturer In India.

- Material Specification Chart Of Stainless Steel 410 Tube Plug

- Stainless Steel 410 Tube Plug Equivalent Grade

- Most Commonly used Stainless Steel 410 Tube Plug Types

- Stainless Steel 410 Tube Plug Sizes

- Stainless Steel 410 Threaded Tapered Plug Sizes

- Stainless Steel 410 Two-Piece Metal Tube Plug Sizes

- Stock List Of Stainless Steel 410 Tube Plug

- Chemical Composition of SS 410 Tube Plug

- Mechanical Properties of Stainless Steel 410 Tube Plug

- Stainless Steel 410 Tube Plug Uses and Application

- Stainless Steel 410 Tube Plug Export Countries

The installation technique for stainless steel 410 tube plugs is similar to that of stainless steel 321 tube plugs, and typically involves the following steps :

Cleaning : The tube must be thoroughly cleaned and free of any debris or contaminants before the plug is inserted.

Measuring : The correct size of the plug must be determined and selected based on the size of the tube.

Insertion : The plug is inserted into the tube and then expanded using a mandrel or tool until it is securely in place.

Testing : The installed plug should be tested to ensure it is properly sealed and securely in place.

Material Specification Chart Of Stainless Steel 410 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Stainless Steel 410 Tube Plug Equivalent Grade

| Grade | UNS | AFNOR | W.N. | JIS | GOST | EN | UNI | ONORM | SIS |

| SS 410 | S41000 | – | 1.4006 | SUS 410 | – | X12Cr13 | – | – | – |

Most Commonly used Stainless Steel 410 Tube Plug Types

SS 410 Tapered Tube Plug

SS 410 Heat Exchanger Tube Plug

SS 410 Threaded Tapered Plug

SS 410 One-Piece Tube Plug

SS 410 Two-Piece Tube Plug

SS 410 Metal Tapered Tube Plug

SS 410 Expandable Tube Plug

SS 410 Boiler Tube Plug

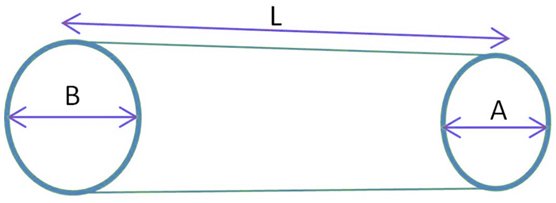

Stainless Steel 410 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Stainless Steel 410 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Stainless Steel 410 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Stainless Steel 410 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of SS 410 Tube Plug

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Tie |

| SS 410 | 0.15 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5 – 13.5 | – | 0.75 | – |

Mechanical Properties of Stainless Steel 410 Tube Plug

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.74 g/cm3 | 1480 °C (2790 °F) | Psi – 74000 , MPa – 510 | Psi – 42000 , MPa – 290 | 34 % |

Stainless Steel 410 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment