Stainless Steel 440B / 440C Tube Plug

SS 440C Header Plug, Suppliers of SS 440C Heat Exchanger Tube Plug, Stainless Steel 440B Tapered Tube Plug, Stainless Steel 440B Tube Plug, 440C SS Two-Piece Tube Plug Manufacturer India, Stainless Steel 440C Tube Plug At Factory Price In India.

Vintex Steel & Engg. Co. is Exporter, Manufacturer, and Supplier of SS 440c / 440b Tube Plug, which are molybdenum-bearing austenitic stainless steels. Stainless-steel ASTM 410 Tube Plug isn’t suggested to be used at sub-zero temperatures because of a crucial drop as a result properties enduring with most steels apart from the steel varieties. we offer 440C Stainless Steel Tube Plug in different sizes, grades and thickness as per custom-made demands provided by our customers at a very reasonable price. To serve escalating requirement of our clients.

Stainless Steel 440B Boiler Tube Plug, UNS S44003 Tube Plug, SS 440C High Pressure Tube Plug, 440C SS One-Piece Tube Plug Stockist, DIN 1.4122 Condenser Tube Plug Supplier, 1.4125 Tube Plug, UNS S44004 Metal Tapered Tube Plugs, 440C SS Expansion Tube Plug Manufacturer In India.

- Material Specification Chart Of Stainless Steel 440B / 440C Tube Plug

- Stainless Steel 440B / 440C Tube Plug Equivalent Grade

- Most Commonly used Stainless Steel 440B / 440C Tube Plug Types

- Stainless Steel 440B / 440C Tube Plug Sizes

- Stainless Steel 440B / 440C Threaded Tapered Plug Sizes

- Stainless Steel 440B / 440C Two-Piece Metal Tube Plug Sizes

- Stock List Of Stainless Steel 440B / 440C Tube Plug

- Chemical Composition of SS 440B / 440C Tube Plug

- Mechanical Properties of Stainless Steel 440B / 440C Tube Plug

- Stainless Steel 440B / 440C Tube Plug Uses and Application

- Stainless Steel 440B / 440C Tube Plug Export Countries

UNS S44004 Tube Plug also is utilized in a whole lot of industries for numerous distinctive purposes, along with for kitchen device and appliances. Meanwhile, it refers to a decrease carbon content material to allow for more corrosion safety whilst welding. Stainless Steel UNS S44003 Tube Plug also are taken into consideration to be because the maximum wieldable of the excessive-alloy steels and may be welded through all fusion and resistance welding processes.

Material Specification Chart Of Stainless Steel 440B / 440C Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Stainless Steel 440B / 440C Tube Plug Equivalent Grade

| STANDARD | DIN | UNS | JIS | GB |

| SS 440B | 1.4122 | S44003 | SUS 440B | 8Cr17 |

| SS 440C | 1.4125 | S44004 | SUS 440C | 11Cr17 / 9Cr18Mo |

Most Commonly used Stainless Steel 440B / 440C Tube Plug Types

SS 440B / 440C Tapered Tube Plug

SS 440B / 440C Heat Exchanger Tube Plug

SS 440B / 440C Threaded Tapered Plug

SS 440B / 440C One-Piece Tube Plug

SS 440B / 440C Two-Piece Tube Plug

SS 440B / 440C Metal Tapered Tube Plug

SS 440B / 440C Expandable Tube Plug

SS 440B / 440C Boiler Tube Plug

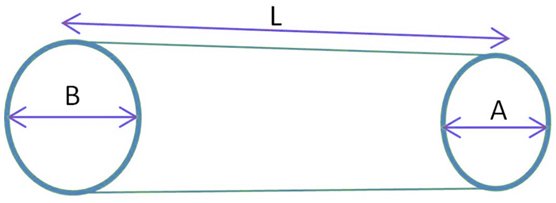

Stainless Steel 440B / 440C Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Stainless Steel 440B / 440C Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Stainless Steel 440B / 440C Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Stainless Steel 440B / 440C Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of SS 440B / 440C Tube Plug

| Grades | C | Si | Mn | P | S | Cr | Mo | Cu | Ni |

| 440B | 0.75-0.95 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.75 | (≤0.5) | (≤0.5) |

| 440C | 0.95-1.2 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0.03 | 16.0-18.0 | ≤0.75 | (≤0.5) | (≤0.5) |

Mechanical Properties of Stainless Steel 440B / 440C Tube Plug

| Density | Melting Point | Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

|---|---|---|---|---|

| 7.6 g/cm³ | 1482 °C | 110 | 65 | 14 |

Stainless Steel 440B / 440C Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment