Super Duplex Steel S32750 / S32760 Tube Plug

Super Duplex S32750 Tapered Tube Plug, S32760 Super Duplex Two-Piece Tube Plug Manufacturer India, Super Duplex Stainless Steel S32750 Tube Plug, Suppliers of Super Duplex 2507 Heat Exchanger Tube Plug, SDSS S32760 Header Plug At Factory Price In India.

Vintex Steel & Engg. Co. is a Exporter & Supplier of Super Duplex S32750 / S32760 Tube Plug, In India. we provide those in various grades and variety together with made-to-order specification. We as nicely provide an enormous series of those which can be available in diverse thickness and width. We have a broad range of UNS S32750 Tube Plugs that are delivered across the globe to our clients. Duplex 32750 is an alloy of 3% Molybdenum,22% Chromium, and about 5-6% Nickel. 32750 is an austenitic-ferritic stainless steel alloy. DIN 1.4410 Tube Plug additionally has a few terrific functions to provide together with corrosion resistance, excessive energy, durability and more.

Super Duplex Steel 2507 Expansion Tube Plug, S32760 Ferritic Super Duplex Steel One-Piece Tube Plug Stockist, UNS S32760 Metal Tapered Tube Plugs, UNS S32750 Tube Plug, Super Duplex S32750 Boiler Tube Plug, Super Duplex S32760 Tube Plug, SAF 2507 High Pressure Tube Plug, 1.4501 Tube Plug, DIN 1.4410 Condenser Tube Plug Supplier Manufacturer In India.

- Material Specification Chart Of Super Duplex S32750 / S32760 Tube Plug

- Super Duplex S32750 / S32760 Tube Plug Equivalent Grade

- Most Commonly used Super Duplex S32750 / S32760 Tube Plug Types

- Super Duplex Steel S32750 / S32760 Tube Plug Sizes

- Super Duplex S32750 / S32760 Threaded Tapered Plug Sizes

- Super Duplex S32750 / S32760 Two-Piece Metal Tube Plug Sizes

- Stock List Of Super Duplex Steel S32750 / S32760 Tube Plug

- Chemical Composition of Super Duplex S32750 / S32760 Tube Plug

- Mechanical Properties of Super Duplex S32750 / S32760 Tube Plug

- Super Duplex S32750 / S32760 Tube Plug Uses and Application

- Super Duplex Steel S32750 / S32760 Tube Plug Export Countries

It is the superior carbon composition version and validates better-excellent of creep residences and excessive temperature. Available in different dimensions and grades which are being offered in different sizes and shapes as per customers need. UNS S32750 Tube Plug has enormous strength and stress corrosion cracking resistance and bear high steam pressure. Alloy 2507 Tube Plug is a better nickel, molybdenum and chromium shape that’s taken into consideration specifically for stepped forward corrosion resistance and energy.

Material Specification Chart Of Super Duplex S32750 / S32760 Tube Plug

| Tube Size | 0.375″ to 3.000″ (9.5 – 76.2mm) OD |

|---|---|

| Maximum Pressure | 150 PSI |

| Length | Max 6 in 152.4 mm |

Super Duplex S32750 / S32760 Tube Plug Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 |

| Super Duplex 2507 | 1.4501 | S32760 |

Most Commonly used Super Duplex S32750 / S32760 Tube Plug Types

Super Duplex 2507 Tapered Tube Plug

Super Duplex 2507 Heat Exchanger Tube Plug

Super Duplex 2507 Threaded Tapered Plug

Super Duplex 2507 One-Piece Tube Plug

Super Duplex 2507 Two-Piece Tube Plug

Super Duplex 2507 Metal Tapered Tube Plug

Super Duplex 2507 Expandable Tube Plug

Super Duplex 2507 Boiler Tube Plug

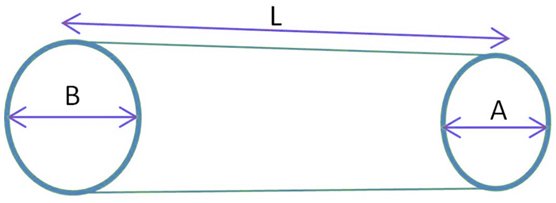

Super Duplex Steel S32750 / S32760 Tube Plug Sizes

| Metal Tapered Tube Plugs – Tube Plug Sizing Chart | ||||

| Tube OD | Gauge | Dimension (Inches) | ||

| “A” | “B” | “L” | ||

| Small End | Large End | Length | ||

| 1/4″ | 18-24 | 0.141″ | 0.235″ | 1-1/4″ |

| 3/8″ | 12-24 | |||

| 3/8″ | 15-24 | 0.213″ | 0.371″ | 1-3/4″ |

| 1/2″ | 13-15 | |||

| 1/2″ | 15-24 | 0.337″ | 0.495″ | |

| 5/8″ | 12-14 | |||

| 5/8″ | 14-24 | 0.449″ | 0.625″ | |

| 3/4″ | 10-14 | |||

| 3/4″ | 14-24 | 0.564″ | 0.750″ | |

| 7/8″ | 10-13 | |||

| 1″ | 8-9 | |||

| 7/8″ | 15-24 | 0.706″ | 0.875″ | |

| 1″ | 10-15 | |||

| 1″ | 13-18 | 0.776″ | 0.934″ | |

| 1″ | 18-24 | 0.892″ | 1.050″ | |

| 1-1/8″ | 13-17 | |||

| 1-1/8″ | 15-24 | 0.949″ | 1.125″ | 2″ |

| 1-1/4″ | 10-14 | |||

| 1-1/4″ | 13-19 | 1.010″ | 1.186″ | |

| 1-1/4″ | 19-24 | 1.147″ | 1.323″ | |

| 1-1/2″ | 10-24 | 1.200″ | 1.495″ | 3″ |

| 1-1/2″ | 14-24 | 1.305″ | 1.600″ | |

| 1-3/4″ | 6-13 | |||

| 1-3/4″ | 14-22 | 1.575″ | 1.870″ | |

| 2″ | 6-13 | |||

| 2″ | 12-22 | 1.700″ | 1.995″ | |

| 2-1/4″ | 6-13 | 1.805″ | 2.100″ | |

| 2-1/2″ | 5-18 | 2.000″ | 2.375″ | |

| 2-3/4″ | 4-10 | 2.232″ | 2.500″ | |

| 3″ | 5-12 | 2.524″ | 2.834″ | 4″ |

| 3″ | 10-23 | 2.625″ | 3.000″ | |

| 3-1/4″ | 7-14 | 2.875″ | 3.125″ | |

| 3-1/4″ | 13-23 | 3.010″ | 3.250″ | |

| 3-1/2″ | 7-12 | 3.125″ | 3.375″ | |

| 3-1/2″ | 13-23 | 3.260″ | 3.500″ | |

| 3-3/4″ | 5-12 | 3.274″ | 3.567″ | |

| 3-3/4″ | 13-23 | 3.510″ | 3.750″ | |

| 4″ | 5-12 | 3.524″ | 3.817″ | |

| 4″ | 13-23 | 3.782″ | 4.000″ | |

Super Duplex S32750 / S32760 Threaded Tapered Plug Sizes

| Threaded Tapered Plugs | |||

|---|---|---|---|

| Max Hole Size | Part No. | Width | Hex Size |

| 0.350″ | TTP-375 | 0.365″ | 3/8″ |

| 0.450″ | TTP-500 | 0.480″ | 1/2″ |

| 0.580″ | TTP-625 | 0.615″ | 5/8″ |

| 0.710″ | TTP-750 | 0.730″ | 3/4″ |

| 0.835″ | TTP-875 | 0.855″ | 7/8″ |

| 0.950″ | TTP-1000 | 0.975″ | 1″ |

| 1.150″ | TTP-1125 | 1.100″ | 1 1/8″ |

| 1.200″ | TTP-1250 | 1.220″ | 1 1/4″ |

| 1.320″ | TTP-1375 | 1.345″ | 1 3/8″ |

| 1.450″ | TTP-1500 | 1.470″ | 1 1/2″ |

Super Duplex S32750 / S32760 Two-Piece Metal Tube Plug Sizes

| Metal Tapered Two Piece Plugs – Tube Plug Sizing Chart | |||

|---|---|---|---|

| Tube OD | Tube ID Range | Pin Size | Ring Size |

| 3/8″ | 0.283 – 0.377 | TP – 1 | TPR-0375 |

| 1/2″ | 0.283 – 0.377 | TP – 1 | TPR-0500-1 |

| 0.384 – 0.503 | TP – 2 | TPR-0500-2 | |

| 5/8″ | 0.384 – 0.503 | TP – 2 | TPR-0625-2 |

| 0.480 – 0.635 | TP – 3 | TPR-0625-3 | |

| 3/4″ | 0.480 – 0.635 | TP – 3 | TPR-0750-3 |

| 0.616 – 0.759 | TP – 4 | TPR-0750-4 | |

| 1″ | 0.616 – 0.759 | TP – 4 | TPR-1000-4 |

| 0.730 – 0.840 | TP – 5 | TPR-1000-5 | |

| 0.830 – 1.008 | TP – 6 | TPR-1000-6 | |

| 1 1/8″ | 0.730 – 0.840 | TP – 5 | TPR-1125-5 |

| 0.830 – 1.008 | TP – 6 | TPR-1125-6 | |

| 0.930 – 1.130 | TP – 7 | TPR-1125-7 | |

| 1 1/4″ | 0.930 – 1.130 | TP – 7 | TPR-1250-7 |

| 0.992 – 1.261 | TP – 8 | TPR-1250-8 | |

| 1 1/2″ | 1.180 – 1.240 | TP – 9 | TPR-1500-9 |

| 1.242 – 1.342 | TP – 10 | TPR-1500-10 | |

| 1.344 – 1.495 | TP – 11 | TPR-1500-11 | |

| 1.380 – 1.510 | TP – 12 | TPR-1500-12 | |

| 2″ | 1.680 – 1.856 | TP – 13 | TPR-2000-13 |

| 1.742 – 2.020 | TP – 14 | TPR-2000-14 | |

Other Related Products

Test Certificates Of Super Duplex Steel S32750 / S32760 Tube Plug

- Hydrostatic Test

- Chemical Analysis – Spectro Analysis

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Mechanical Testing Such as Tensile, Elongation

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Micro Test

- Radiography Test

- Flattening Test

Chemical Composition of Super Duplex S32750 / S32760 Tube Plug

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

Mechanical Properties of Super Duplex S32750 / S32760 Tube Plug

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 2507 | 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 116000, MPa – 800 | Psi – 80000, MPa – 550 | 15 % |

Super Duplex S32750 / S32760 Tube Plug Uses and Application

- Nuclear Energy Sector

- Offshore & Chemical Industry

- Engineering & Aerospace Industry

- Automotive industry

- Oil & Gas Industries

- Power Generation

- Architectural Trim and Molding

- Kitchen Benches, Sinks, Equipment

- Food Processing Equipment